Filling machine

A filling machine and filling tube technology, applied in the field of machinery, can solve problems such as poor sterilization effect, and achieve the effects of improving sterilization effect, enhancing thermal insulation effect, and enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

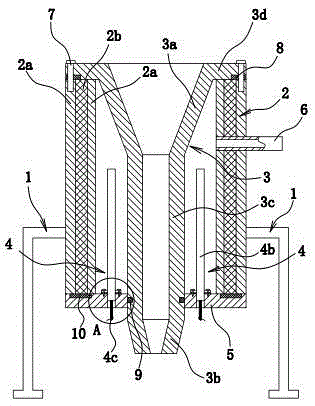

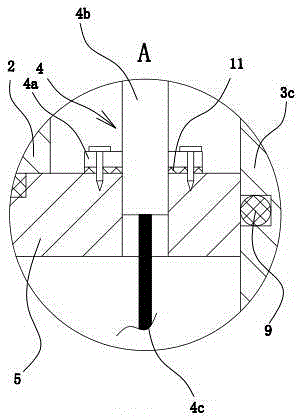

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

[0024] Such as figure 1 As shown, the filling machine is composed of a bracket 1, a support cylinder 2, a filling pipe 3, an electric heating pipe 4, a sealing ring 5, and a water inlet pipe 6. Wherein, the filling pipe 3 is made of thermally conductive material, such as iron, copper and the like. The priority filling tube 3 is made of copper. The electric heating tube 4 is a prior art, and its structure is the same as a flange type electric heating tube 4 [application number: 201410323434.5; application publication number: CN 104159334 A]) disclosed in the Chinese patent library.

[0025] The bracket 1 is connected with the support tube 2 to better support the support tube 2 . The filling tube 3 is tubular and inserted into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com