An anti-off and anti-single ring hoisting system

An anti-dropping and lifting ring technology, applied in the direction of drill pipe, casing, drill pipe, etc., can solve the problems of reduced safety and reliability in the operation process, inability to effectively block the lifting ring, and easy rotation of the lifting ring stopper, so as to reduce labor costs. The effect of labor intensity, ensuring lifting safety, and improving lifting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

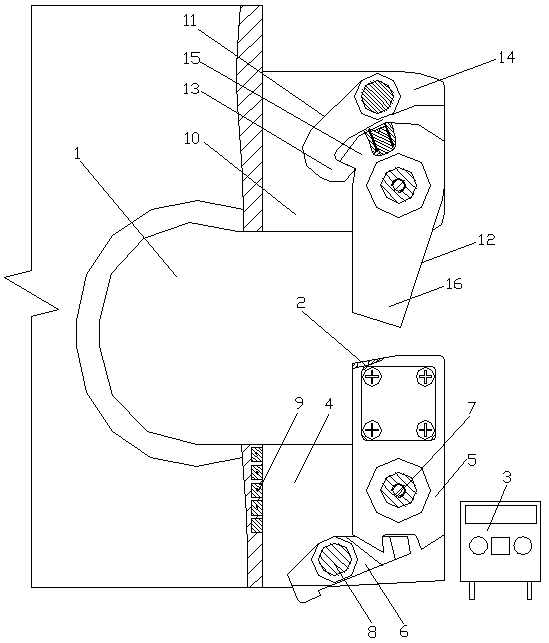

Embodiment 1

[0063] An anti-loosening anti-single-ring lifting system, including anti-off parts arranged in the slots 4 under the lifting lugs on both sides of the elevator, the anti-off parts include a blocking block 5 and a locking block 6 located below the blocking block 5, which block The block 5 is fixed in the lower notch 4 by the first rotating shaft 7, and the lock block 6 is fixed in the lower notch 4 by the second rotating shaft 8, and the blocking block 5 is provided with a lock that matches the locking block 6, The blocking block 5 is locked and connected with the locking block 6, and the blocking block 5 is provided with an inductive part 2 for monitoring the position of the suspension ring, and a trigger block 9 is provided on the inner wall of the lower notch 4; it also includes anti-single-hanging parts and The anti-off mechanism arranged in the upper notch 10 of the lifting lug, the anti-single-hanging part includes a controller 3, the controller 3 is connected with the sen...

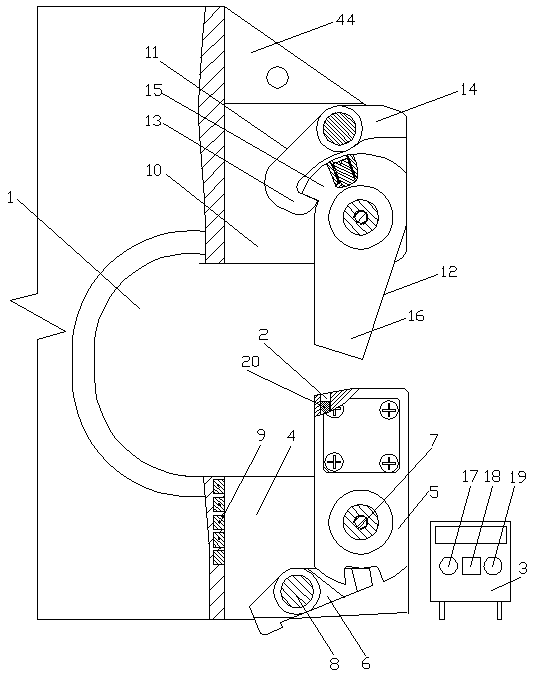

Embodiment 2

[0066] An anti-loosening anti-single-ring lifting system, including anti-off parts arranged in the slots 4 under the lifting lugs on both sides of the elevator, the anti-off parts include a blocking block 5 and a locking block 6 located below the blocking block 5, which block The block 5 is fixed in the lower notch 4 by the first rotating shaft 7, and the lock block 6 is fixed in the lower notch 4 by the second rotating shaft 8, and the blocking block 5 is provided with a lock that matches the locking block 6, The blocking block 5 is locked and connected with the locking block 6, and the blocking block 5 is provided with an inductive part 2 for monitoring the position of the suspension ring, and a trigger block 9 is provided on the inner wall of the lower notch 4; it also includes anti-single-hanging parts and The anti-off mechanism arranged in the upper notch 10 of the lifting lug, the anti-single-hanging part includes a controller 3, the controller 3 is connected with the sen...

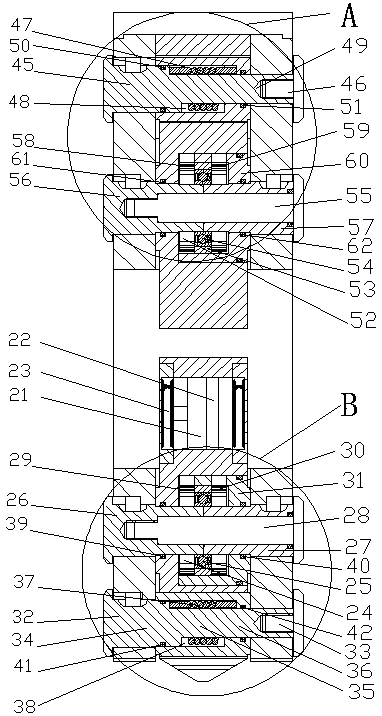

Embodiment 3

[0071] An anti-loosening anti-single-ring lifting system, including anti-off parts arranged in the slots 4 under the lifting lugs on both sides of the elevator, the anti-off parts include a blocking block 5 and a locking block 6 located below the blocking block 5, which block The block 5 is fixed in the lower notch 4 by the first rotating shaft 7, and the lock block 6 is fixed in the lower notch 4 by the second rotating shaft 8, and the blocking block 5 is provided with a lock that matches the locking block 6, The blocking block 5 is locked and connected with the locking block 6, and the blocking block 5 is provided with an inductive part 2 for monitoring the position of the suspension ring, and a trigger block 9 is provided on the inner wall of the lower notch 4; it also includes anti-single-hanging parts and The anti-off mechanism arranged in the upper notch 10 of the lifting lug, the anti-single-hanging part includes a controller 3, the controller 3 is connected with the sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com