Sliding measurement device for automobile front cover assembly

A technology for measuring devices and front covers, applied in measuring devices, instruments, etc., can solve problems such as poor measurement accuracy, inconvenient maintenance, and poor stability, and achieve the effects of high stable operation, convenient maintenance, and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

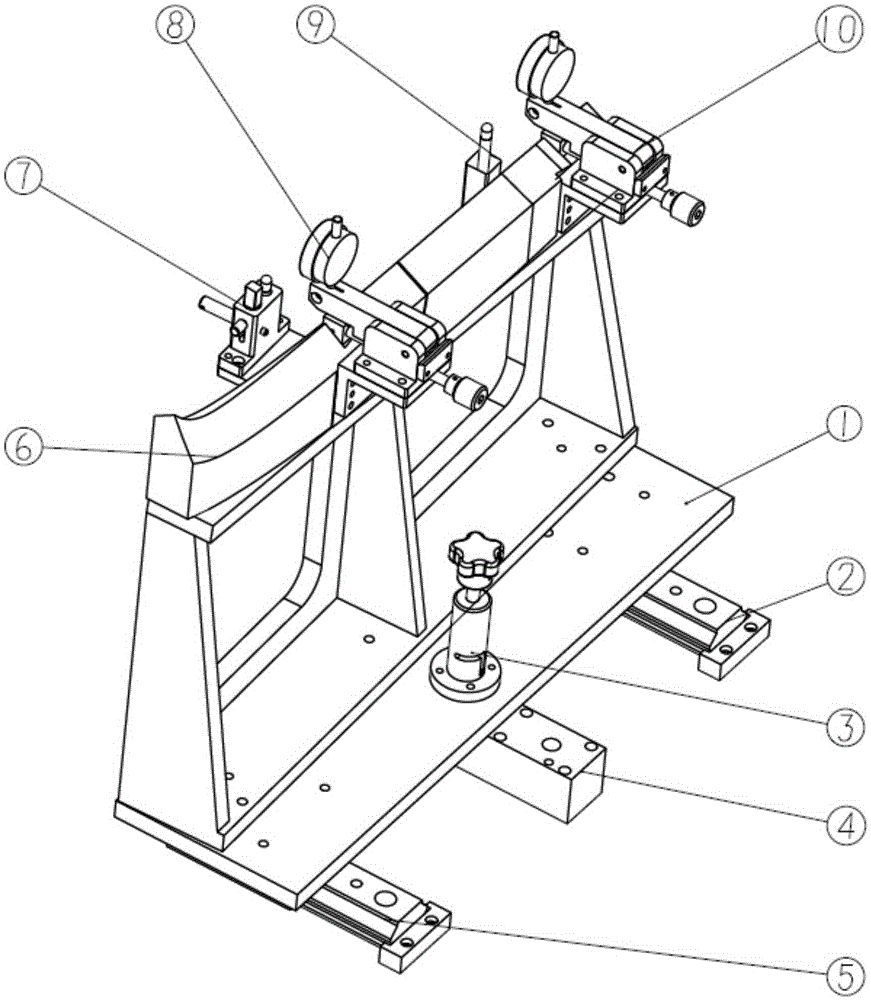

[0022] Such as figure 1 As shown, a sliding measuring device for an automobile front cover assembly includes a sliding component and a measuring component that can slide along the sliding component. The measuring component includes a sliding base plate 1 and a reference adjustment measuring module mounted on the sliding base plate 1. , The reference fixing pin 3 and the reference fixing block 4, when the sliding base plate 1 slides to the set position, the reference fixing pin 3 passes through the sliding base plate 1 and the reference fixing block 4 is connected, and the sliding base plate 1 is locked.

[0023] The sliding assembly is a guide rail sliding mechanism. The sliding assembly includes a first sliding assembly 2 and a second sliding assembly 5 respectively installed on both sides of the lower surface of the sliding bottom plate.

[0024] The reference adjustment measurement module includes a profile reference block 6 and a reference adjustment assembly and a reference m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com