Method for determining the three-dimensional stress based on single drilled rock's deformation measurement

A technology of ground stress and rock mass, applied in the direction of measuring force components, drilling equipment and methods, and measuring devices, can solve problems such as strain measurement dispersion, ground stress tensor calculation result errors, and measurement result errors, and achieve easy Effects of implementing and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for determining the three-dimensional geostress of rock mass based on single borehole deformation measurement, the steps of which are:

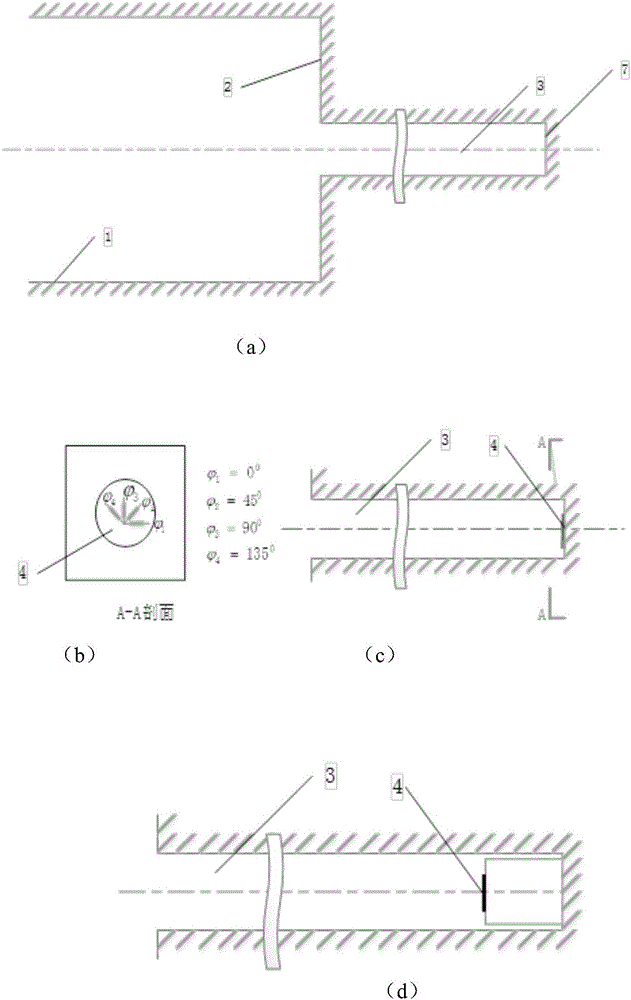

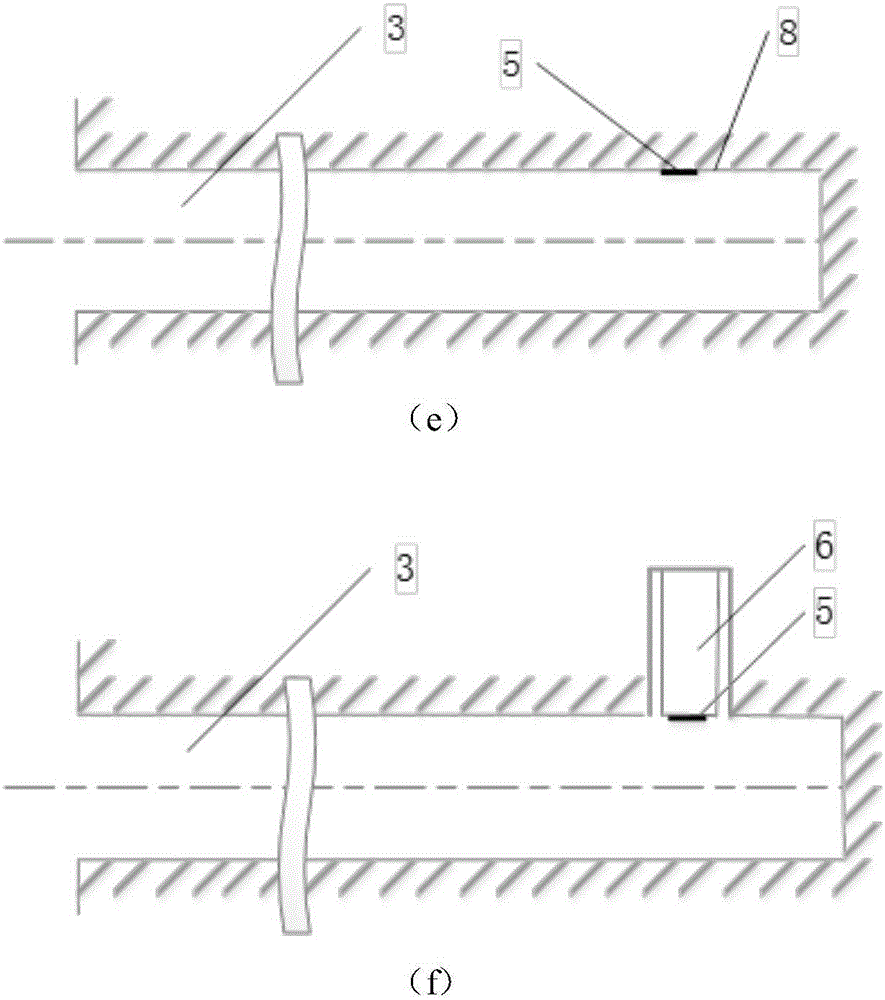

[0028] A. If figure 1 As shown in (a), a horizontal test hole 3 is drilled on the face 2 of the underground roadway 1, and the diameter of the horizontal test hole can be selected as When the depth of the horizontal test hole 3 is far away from the surrounding rock disturbance area of the underground roadway 1, the hole bottom 7 of the horizontal test hole 3 is ground.

[0029] Each strain gage of B, four-component strain bundle 4 is distributed in 45 ° (as figure 1 (b) As shown in section A-A), the diameter of the pasted four-component strain bundle 4 is of round shape. After the four-component strain cluster 4 pasted on the hole bottom 7 of the horizontal test hole is consolidated, the concentric hole construction drilling is carried out along the axis of the original horizontal test hole 3 to repair the bottom surfac...

Embodiment 2

[0034] A method for determining the three-dimensional geostress of rock mass based on single borehole deformation measurement, the steps of which are:

[0035] A. If figure 1 As shown in (a), a horizontal test hole 3 is drilled on the face 2 of the underground roadway 1, and the diameter of the horizontal test hole can be selected as When the depth of the horizontal test hole 3 is far away from the surrounding rock disturbance area of the underground roadway 1, the hole bottom 7 of the horizontal test hole 3 is ground.

[0036] Each strain gage of B, four-component strain bundle 4 is distributed in 45 ° (as figure 1 (b) As shown in section A-A), the diameter of the pasted four-component strain bundle 4 is of round shape. After the four-component strain cluster 4 pasted on the hole bottom 7 of the horizontal test hole is consolidated, the concentric hole construction drilling is carried out along the axis of the original horizontal test hole 3 to repair the bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com