Fiber grating type six-way pressure sensor for deep soft rock stress measurement

A technology of pressure sensor and fiber grating, which is applied in the field of fiber grating six-direction pressure sensor, can solve the problems of small measurement range, difficulty in meeting multi-direction and large range requirements, etc., and achieve large range, comprehensive rock mass stress measurement, and free Effects of Electromagnetic Interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

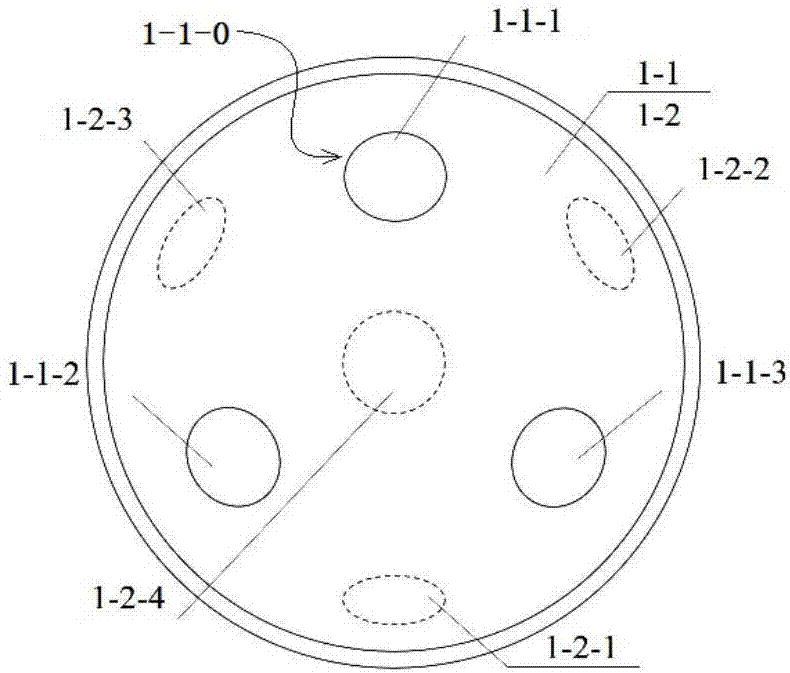

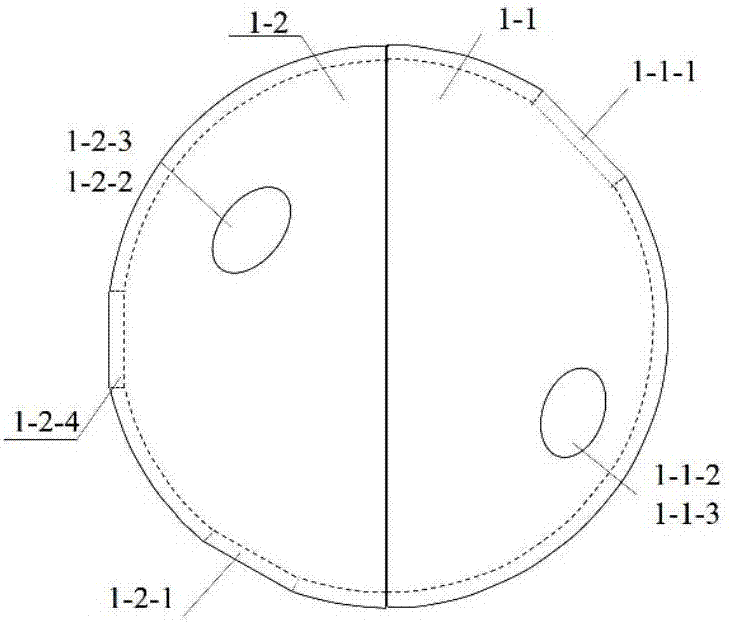

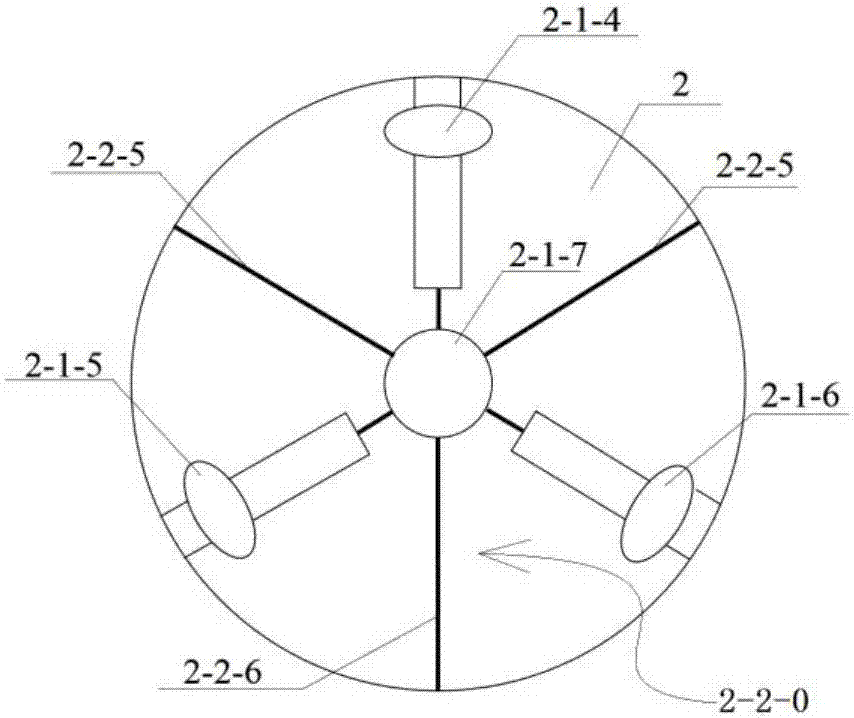

[0037] A fiber grating type six-direction pressure sensor for deep soft rock stress measurement, comprising a solid sphere 2, the upper half of the solid sphere 2 is provided with three pressure sensing unit installation grooves 4-2, and the lower half of the solid sphere 2 is provided with three A pressure sensing unit mounting groove 4-2, the lower half of the solid sphere 2 is also provided with a cylindrical fiber optic groove 2-1-7, and a fiber grating pressure sensing unit 3-2 is arranged in the pressure sensing unit mounting groove 4-2. 0, the optical fiber 3-4 connected to the fiber grating pressure sensing unit 3-0 converges in the cylindrical optical fiber groove 2-1-7 along the optical fiber routing groove 2-2-0 opened on the outer surface of the solid sphere 2, The outer cover of the solid sphere 2 is provided with a spherical shell 1, and the part of the spherical shell 1 corresponding to the position of the cylindrical optical fiber groove 2-1-7 is provided with a...

Embodiment 2

[0057] The angle between the normal line of the sensing surface of the pressure head 3-1 of the three fiber grating pressure sensing units 3-0 installed on the upper half of the solid sphere 2 and the horizontal plane is 45 degrees, and the upper half of the solid sphere 2 is set The adjacent angle between the projection straight lines of the normal of the sensing surface of the indenter 3-1 of the three fiber grating pressure sensing units 3-0 on the horizontal plane is 60 degrees; the lower half of the solid sphere 2 The angle between the normal line of the sensing surface of the pressure head 3-1 of the three fiber grating pressure sensing units 3-0 and the horizontal plane is 60 degrees, and the three fiber gratings arranged in the lower half of the solid sphere 2 The adjacent angle between the projection straight lines of the normal of the sensing surface of the pressure head 3-1 of the pressure sensing unit 3-0 on the horizontal plane is 60 degrees.

[0058] Others are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com