Welding tooling and welding method of motor vibrator

A technology of welding tooling and welding method, applied in the field of welding tooling of motor vibrators, can solve the problems of increasing cost and time, increasing the difficulty of positioning, complex structure, etc., and achieves the effect of easy positioning of the vibrator in the air, cost and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

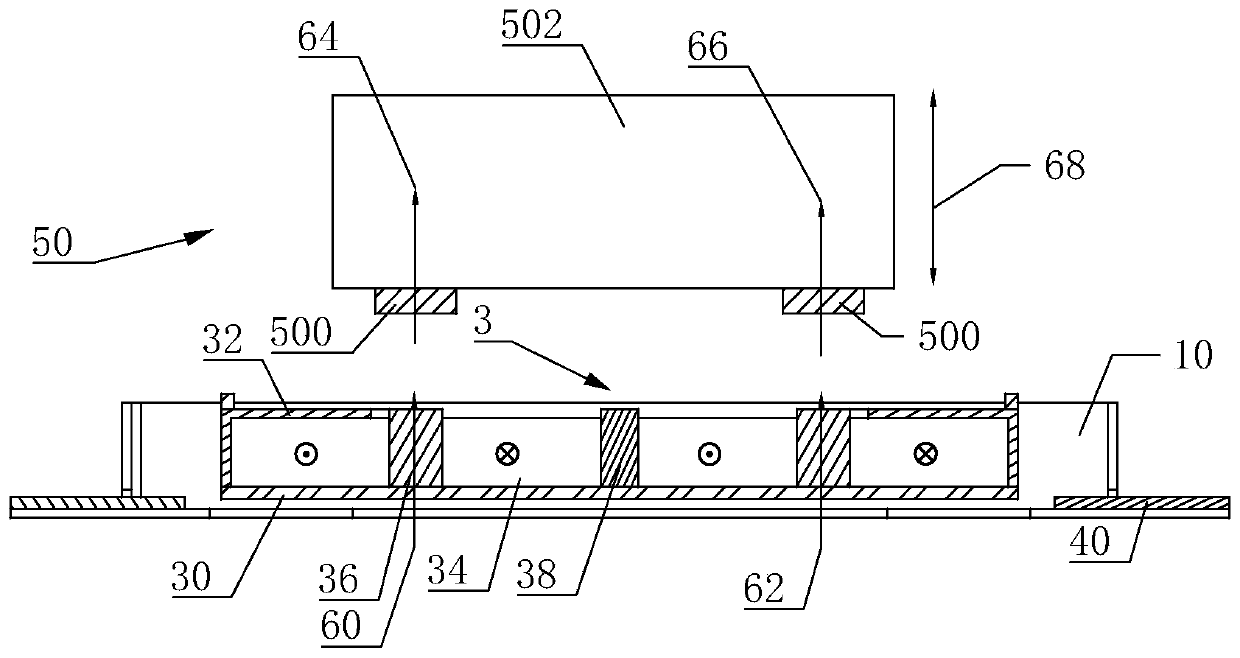

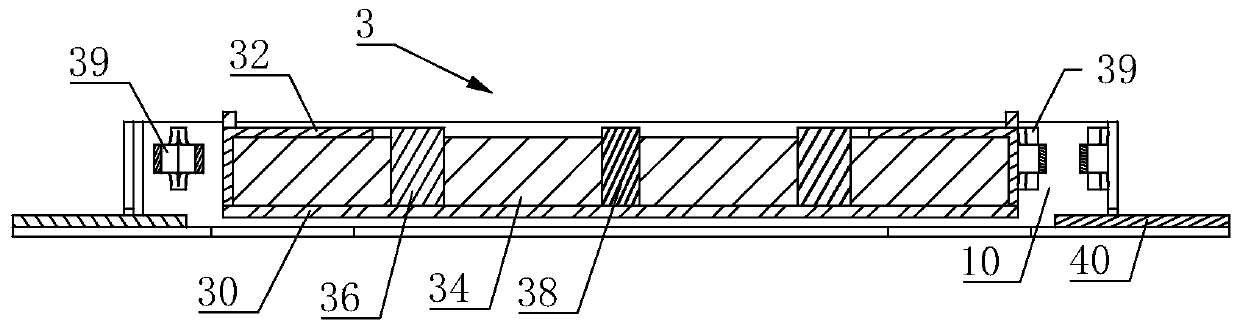

[0036] Such as figure 1 and figure 2 As shown, a welding tool for a motor vibrator includes a supporting component, the supporting component in this embodiment is preferably a mechanical arm 502 ; and a tooling magnet 500 installed at the lower end of the mechanical arm 502 . The number of tooling magnets 500 is at least two, and the two tooling magnets 500 located at the two ends of the mechanical arm 502 are respectively arranged corresponding to the two motor magnets located at the two ends of the motor vibrator 3; the motor magnets are electromagnets, and the tooling magnets The magnetization directions of the magnet 500 and the motor magnet are both vertical and the same.

[0037] The quantity of the tooling magnets 500 of the present invention is the same as that of the motor magnets, so that when welding, the tooling magnets 500 and the motor magnets attract each other one by one to attract the motor vibrator 3 .

[0038] The tooling magnet 500 used in this embodimen...

Embodiment 2

[0048] This embodiment is basically the same as Embodiment 1, the difference is:

[0049] Such as figure 1 and figure 2 As shown, in the welding tool 50 of this embodiment, the tool magnet 500 provided on the mechanical arm 502 is an electromagnet. That is, the fixture magnet 500 becomes an electromagnet after being fed with electric current.

[0050] A welding method for a motor vibrator, comprising the following steps:

[0051] Step 1: Put the motor vibrator 3 on the motor housing 10, place the welding fixture 50 of the motor vibrator 3 on the top of the motor vibrator 3, and make the two fixture magnets 500 located at both ends of the mechanical arm 502 respectively correspond to the vibrator 3 The two motor magnets at both ends correspond to each other. The motor magnet in this embodiment includes a flat voice coil 34 and an armature 36 inserted in the middle of the voice coil; of course, the motor magnet is not limited to the structures listed in this embodiment.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com