A fire extinguishing system using sand positive pressure injection and its realization method

A fire extinguishing system and sand technology, applied in fire rescue, etc., can solve problems such as secondary disasters, easy danger, and poor adaptability, and achieve the effects of strong adaptability, low cost, and wide application locations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment the present invention is further described:

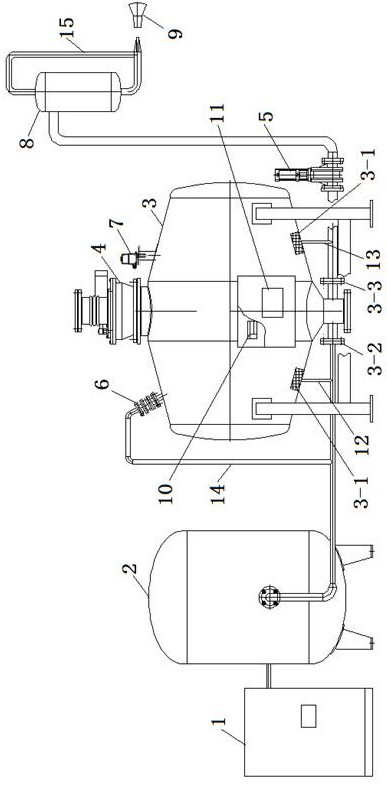

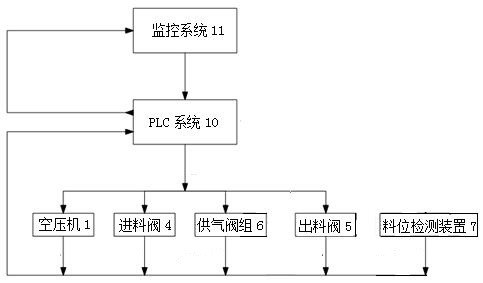

[0022] Such as figure 1 , 2 As shown, a positive pressure jetting fire extinguishing system using sand includes a compressed air system, a sandblasting tank system, an air return system, a control system, and a sandblasting nozzle 9 .

[0023] The compressed air system includes an air compressor 1 and an air storage tank 2.

[0024] The sandblasting tank system includes a sand storage tank 3 , a feed valve 4 , a discharge valve 5 , an air supply valve group 6 , and a material level detection device 7 .

[0025] At the upper end of the sand storage tank 3, a feed valve 4 and a material level detection device 7 are installed respectively, and two disturbing air perforated plate covers 3-1 are installed on the bottom body in the sand storage tank 3. On the sand storage tank 3 body in the perforated plate cover 3-1, the gas transmission pipeline branch pipe II12 and the gas transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com