Rotary drum screen special for gunpowder

A drum sieve and gunpowder technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of low work efficiency, sieving of inflammable and explosive gunpowder materials, time-consuming and labor-intensive problems, and achieve high work efficiency and safety Reliable performance and the effect of saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

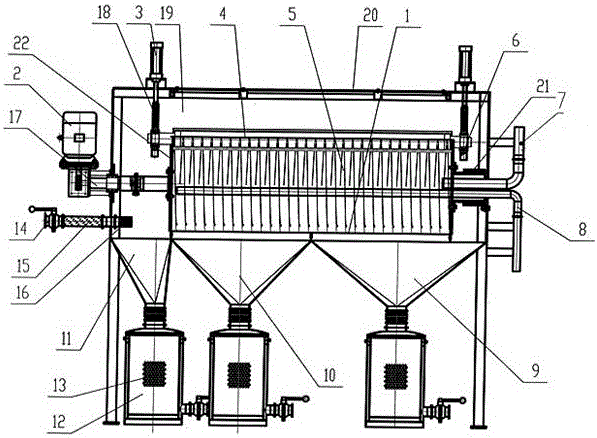

[0007] Describe the embodiment in detail in conjunction with accompanying drawing, it comprises a drum type screen box 19, two air cylinders 3 are installed symmetrically outside the upper cover 20 of the screen box, a cage 22 is installed in the drum below the two air cylinders, and A uniformly distributed material guide belt 5 is installed on the inner wall of the cage circumference, and a screen cleaning roller 4 is installed parallel to the top of the drum, and a vibrator 6 is installed at both ends of the screen cleaning roller. Vibration damping springs 18 are respectively installed between the cylinder heads, an explosion-proof motor 2 is installed at the outer end of the drive shaft 17 of the drum, and a feed pipe is installed in the hollow shaft 21 at the other end of the drum from the outer end upward to the drum 7. A spray pipe 8 is installed below the feed pipe from the outer end of the hollow shaft to the inside of the drum. On the bottom plate 1 of the screen box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com