Steel ball cleaning device

A cleaning device and a technology for steel balls, which are applied in the directions of dry gas arrangement, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of easy friction of steel balls, damage to the spherical surface quality of steel balls, and inability to dry steel balls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below by means of specific embodiments:

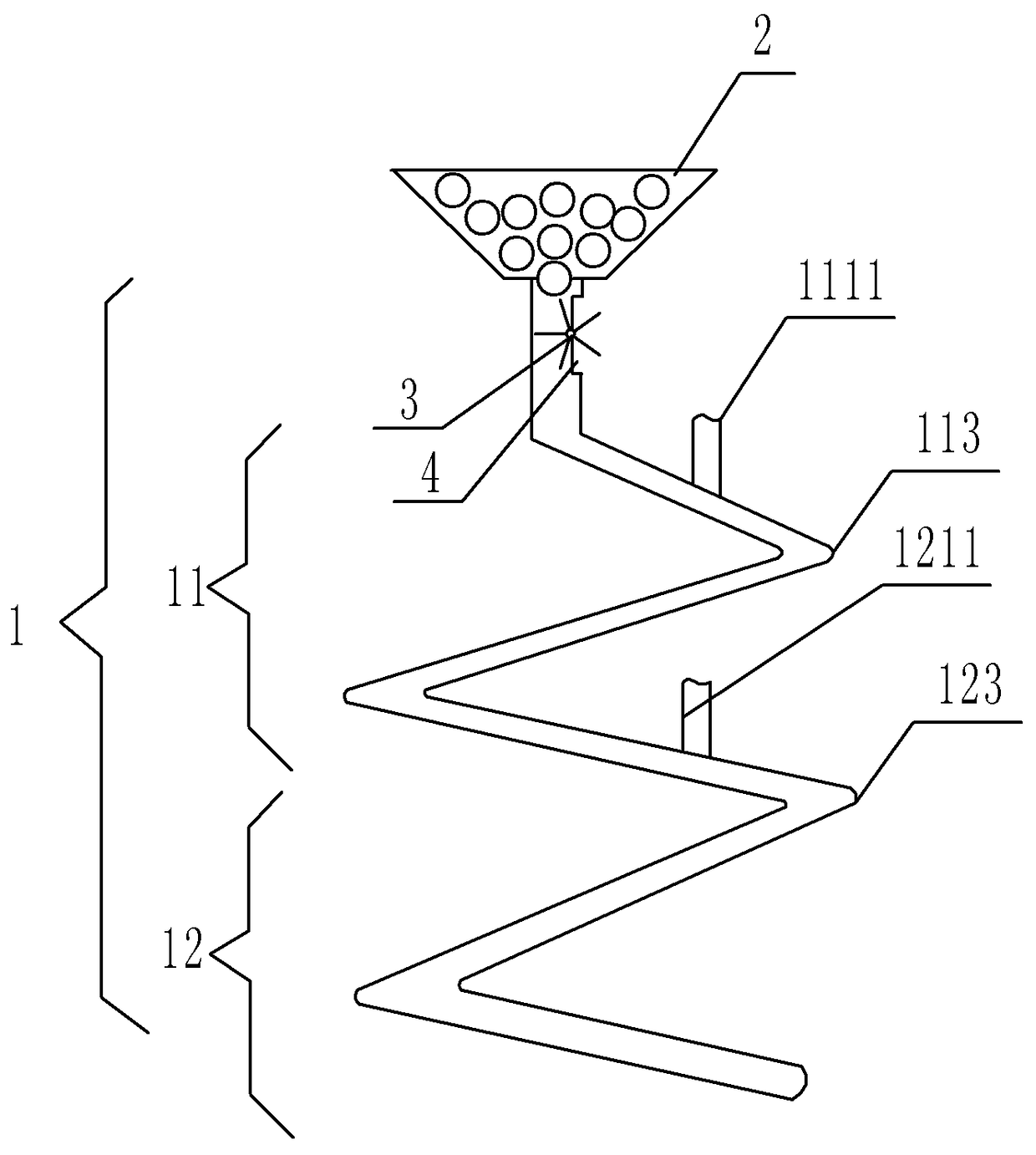

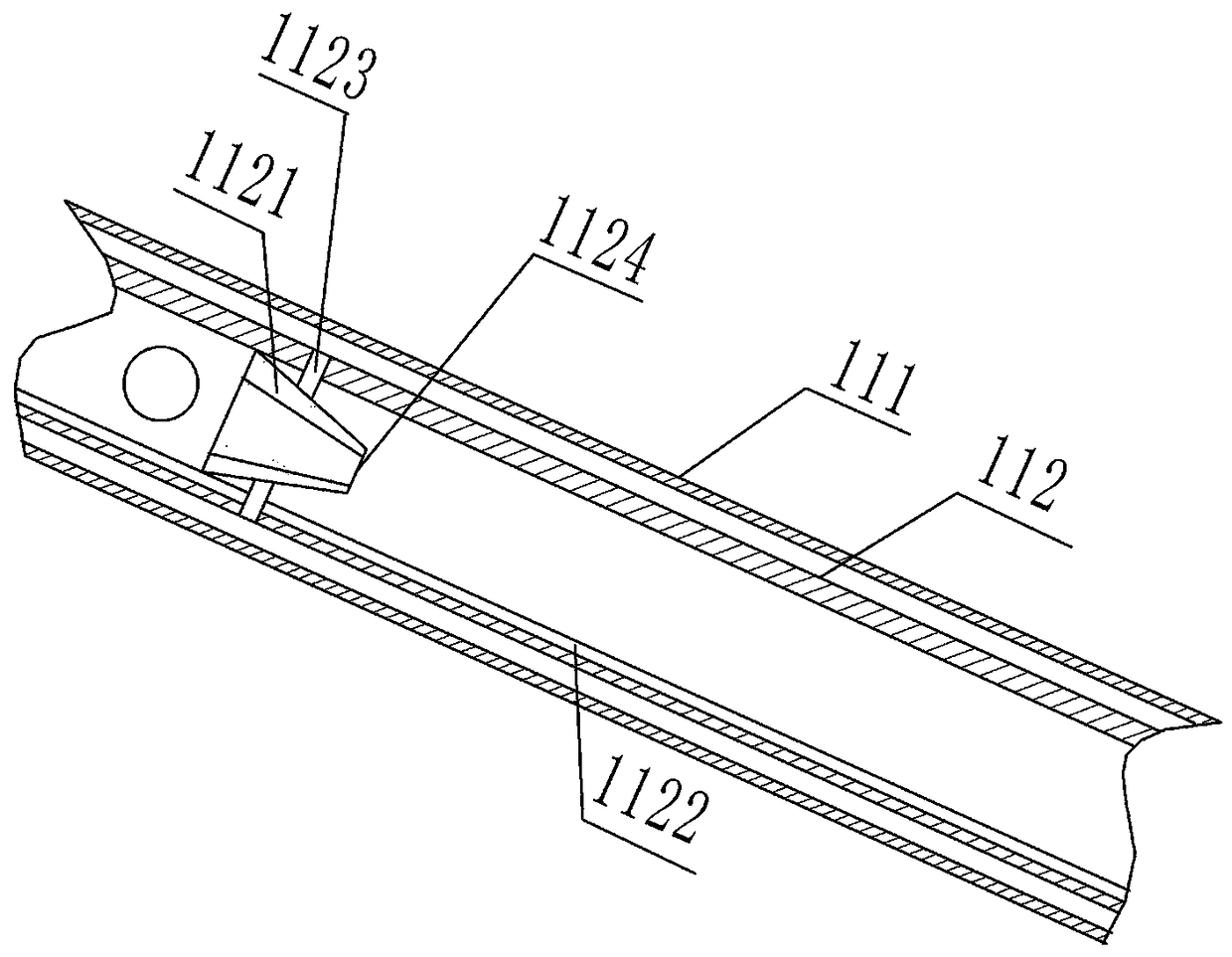

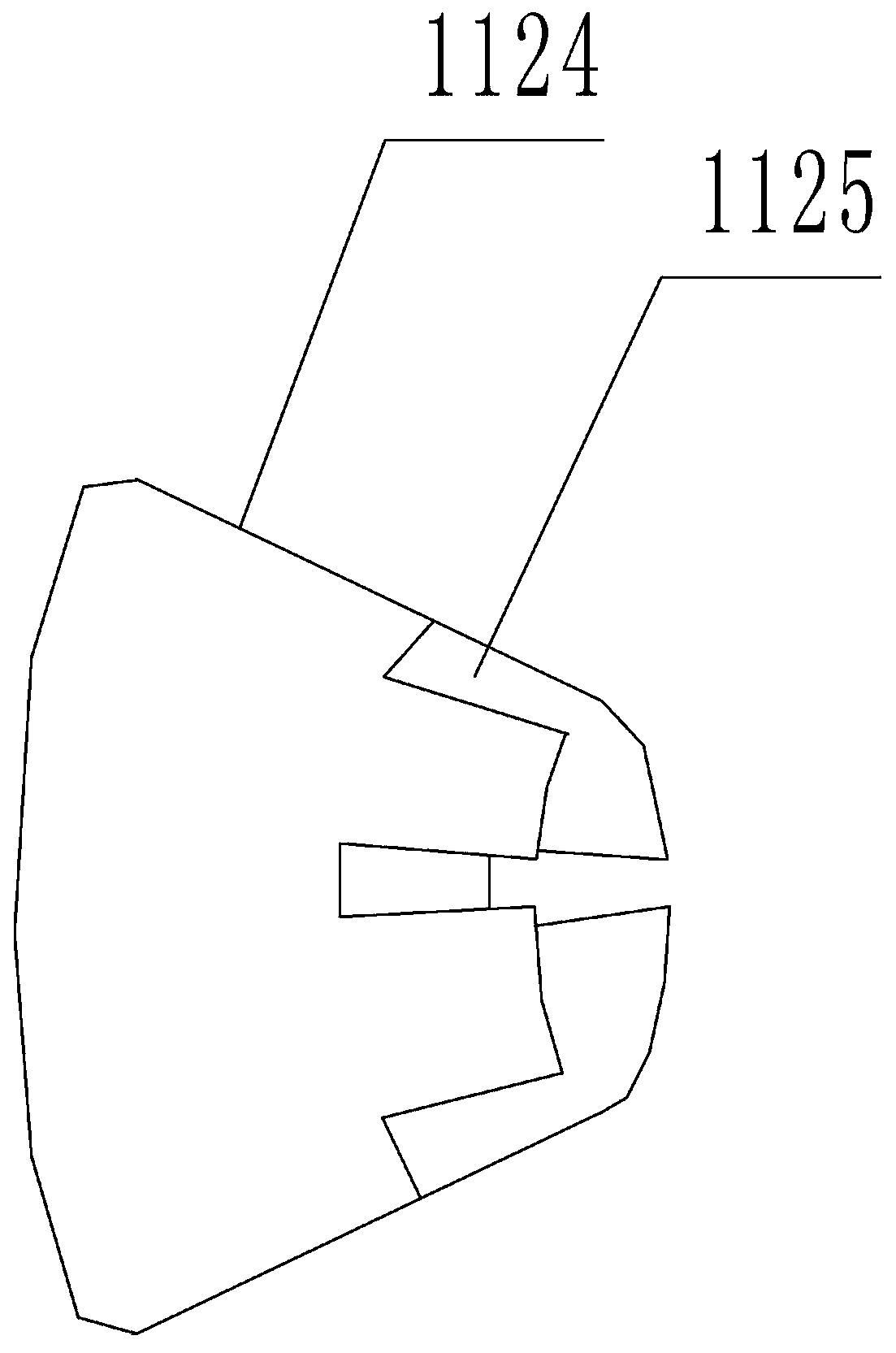

[0027] The reference signs in the accompanying drawings of the description include: cleaning pipeline 1, feed inlet 2, conveying part 3, rotating port 4, cleaning section 11, cleaning outer pipe 111, water inlet pipe 1111, cleaning inner pipe 112, sponge sleeve 1121, guide Sink 1122, water pipe 1123, rubber expansion sleeve 1124, elastic mouth 1125, cleaning section bending part 113, drying section 12, drying outer pipe 121, air blowing pipe 1211, drying inner pipe 122, blowing port 1221, cloth strip 1222. The bending part 123 of the drying section.

[0028] see figure 1 , figure 2 , image 3 with Figure 4 The shown steel ball cleaning device includes a spiral cleaning pipeline 1 that allows only one steel ball to pass through, and the cleaning pipeline 1 is spirally arranged from top to bottom. The upper end of the cleaning pipeline 1 is provided with a funnel-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com