Method of preventing steel coil tensile steel for hot rolled strip

A technology of hot continuous rolling and strip steel, applied in the field of metallurgy, can solve the problems of increasing the overall width deviation of strip steel, increasing the processing cost of users, reducing the yield of finished products, etc., to achieve the effect of ensuring uniformity and avoiding steel drawing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

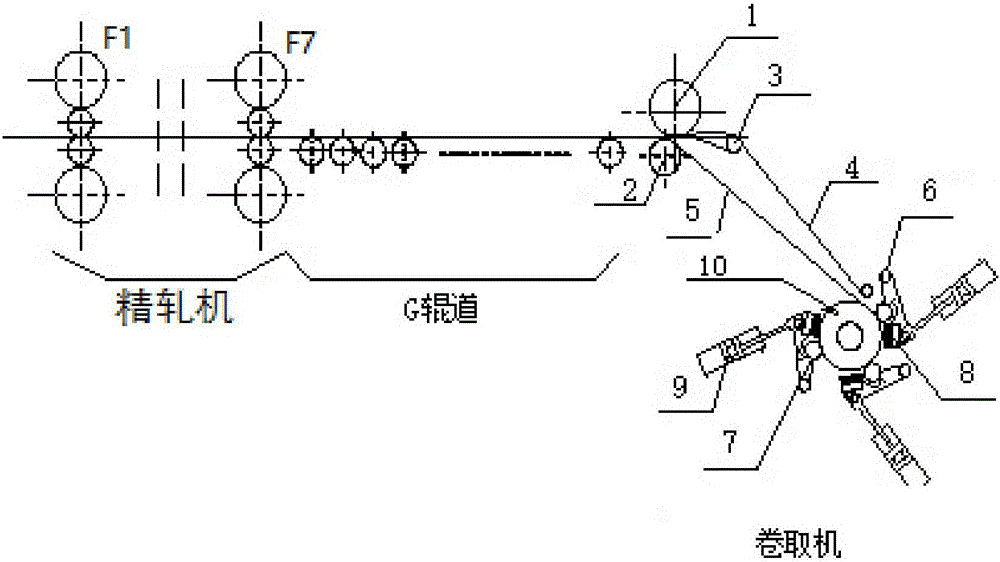

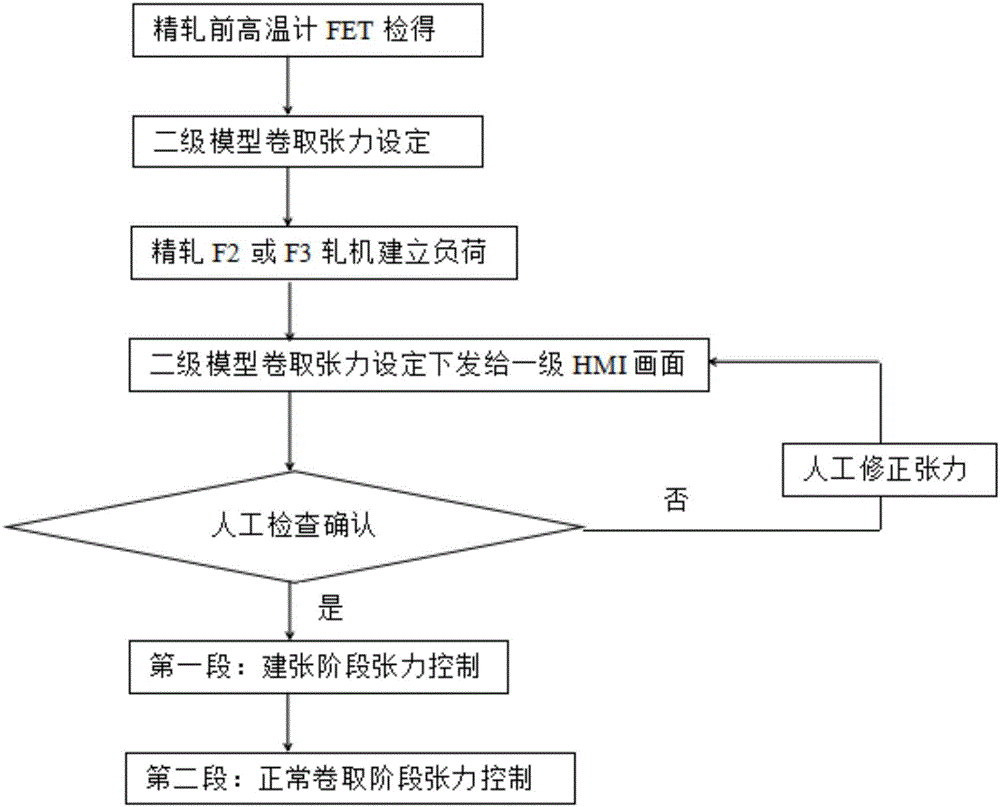

Method used

Image

Examples

specific Embodiment 1

[0033] Specific example 1: strip steel variety SPHC, specification 3.0×1260mm, secondary model setting tension 18KN / mm 2 ;

[0034] After adopting the patent of the present invention, the first stage: the coiling and tension building stage, the actual coiling tension adopts 60% of the tension set by the secondary model, that is, 18×60%=10.8KN / mm 2 ;

[0035] The second stage: After the coiling is normally established, the actual coiling tension returns to the set tension of the secondary model, which is 18KN / mm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com