A continuous drilling machine

A technology of drilling machine and drill bit, which is applied in drilling/drilling equipment, components of boring machine/drilling machine, metal processing equipment, etc., can solve the problems of low processing efficiency, discontinuous production process, time-consuming and laborious, and achieve continuous processing. , The effect of uninterrupted feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above-mentioned objectives, features and advantages of the present invention more obvious and understandable, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

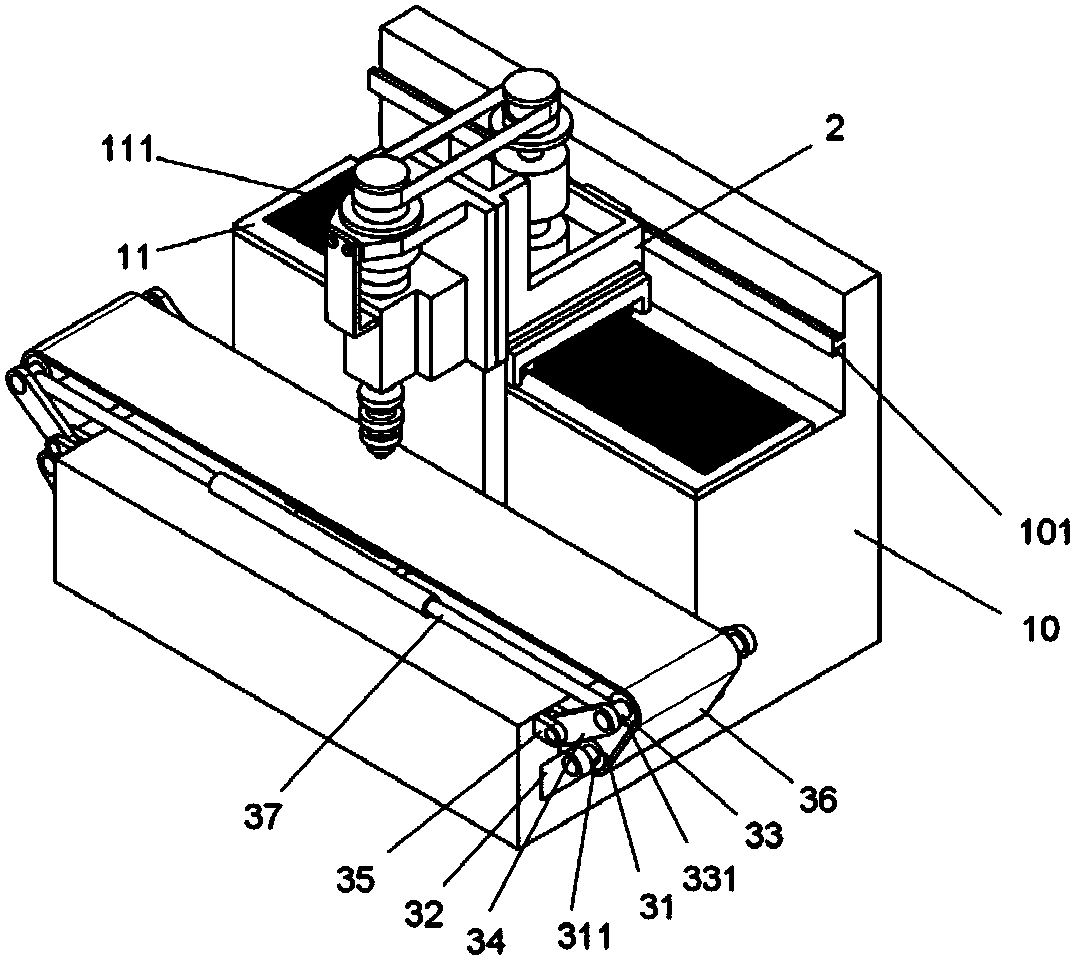

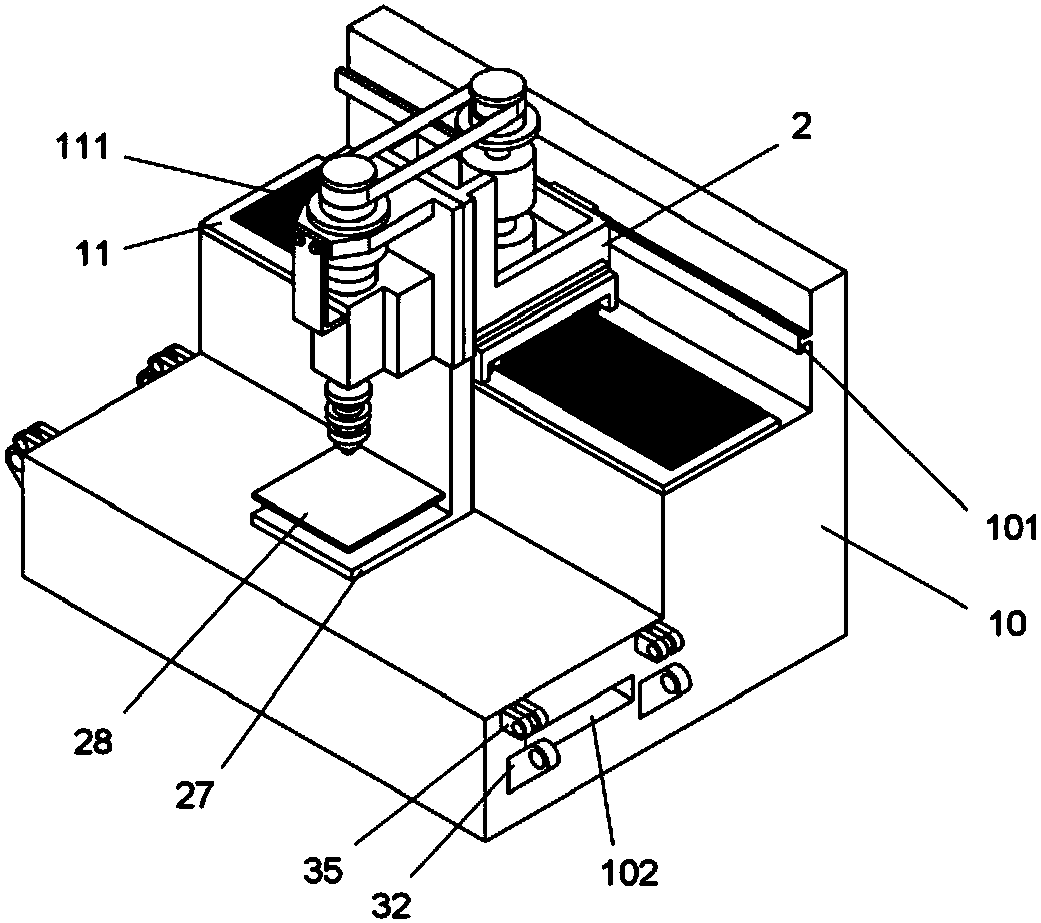

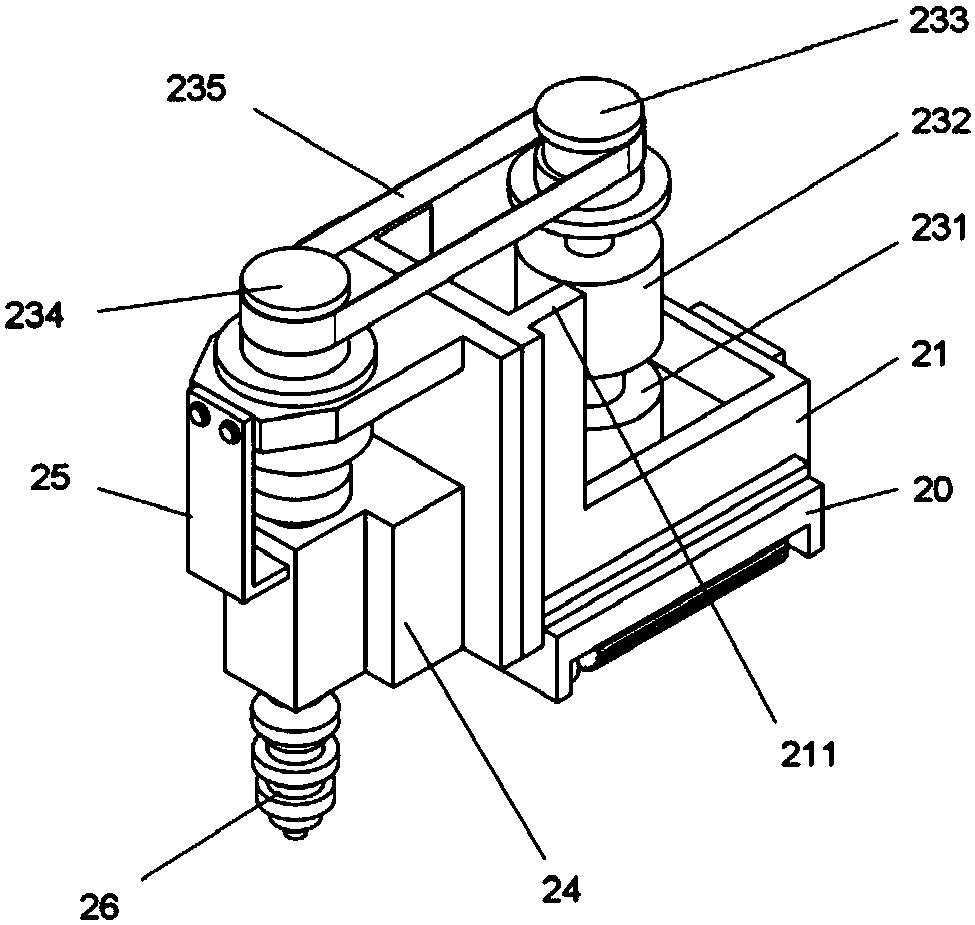

[0019] Such as Figure 1-5 As shown, a continuous drilling machine includes a base 10, the base 10 is stepped, the upper part of the first step of the base 10 is slidably provided with a drilling assembly 2, and the drilling assembly 2 performs For drilling operation, a continuous conveying assembly is arranged directly under the drilling assembly 2; the drilling assembly 2 includes a movable sliding block 20, and a supporting plate 21 is arranged on the upper part of the movable sliding block 20. The supporting plate 21 is L-shaped, and the supporting plate 21 is vertical. There are ribs 211 on both sides of the straight part. The horizontal part of the support plate 21 is provided with a positioning groove. The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com