Cutting equipment of pipeline for water conservancy project

A technology for pipe cutting and water conservancy engineering, applied in metal processing equipment, shearing equipment, pipe shearing devices, etc., can solve the problems of inaccurate cutting size, unsafe cutting process, troublesome operation, etc., and achieve the effect of accurate measurement scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

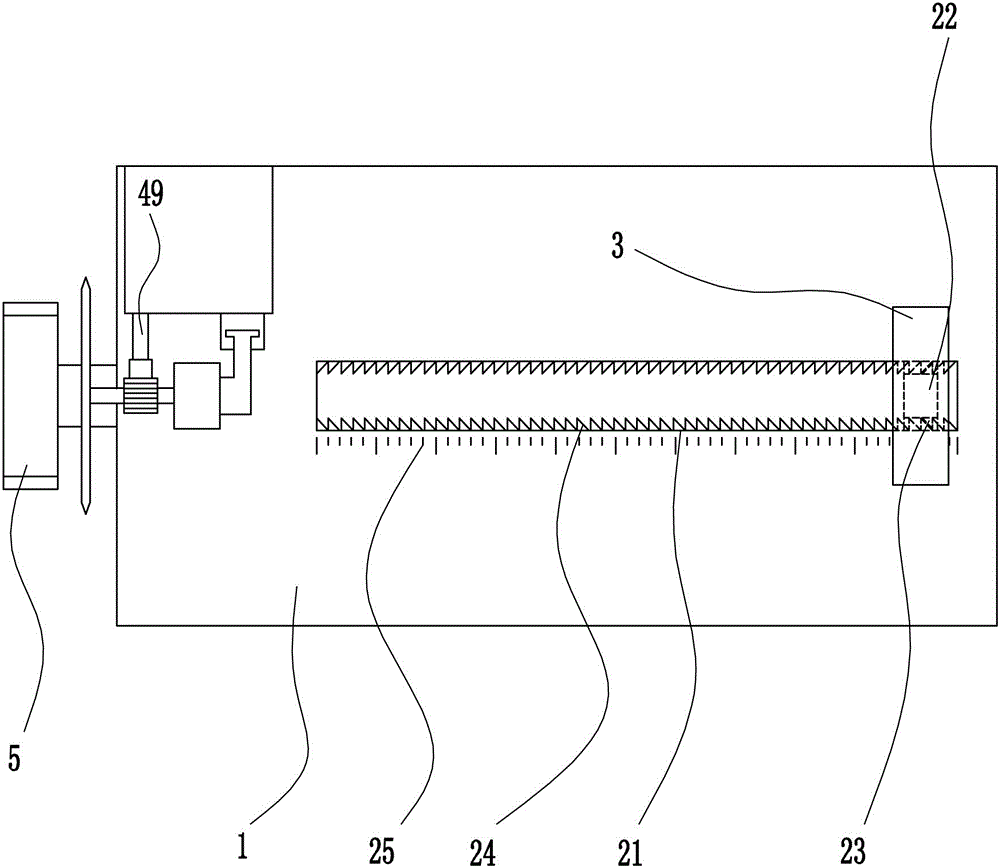

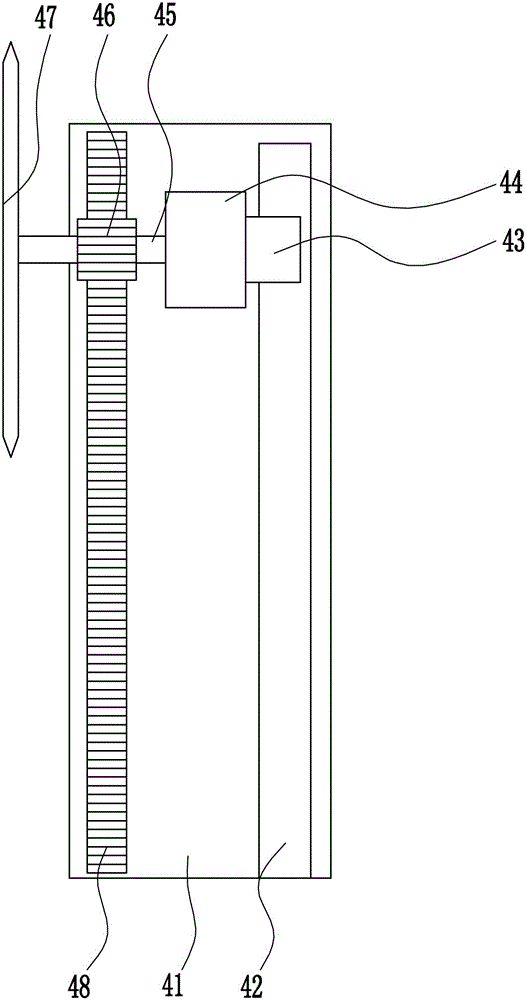

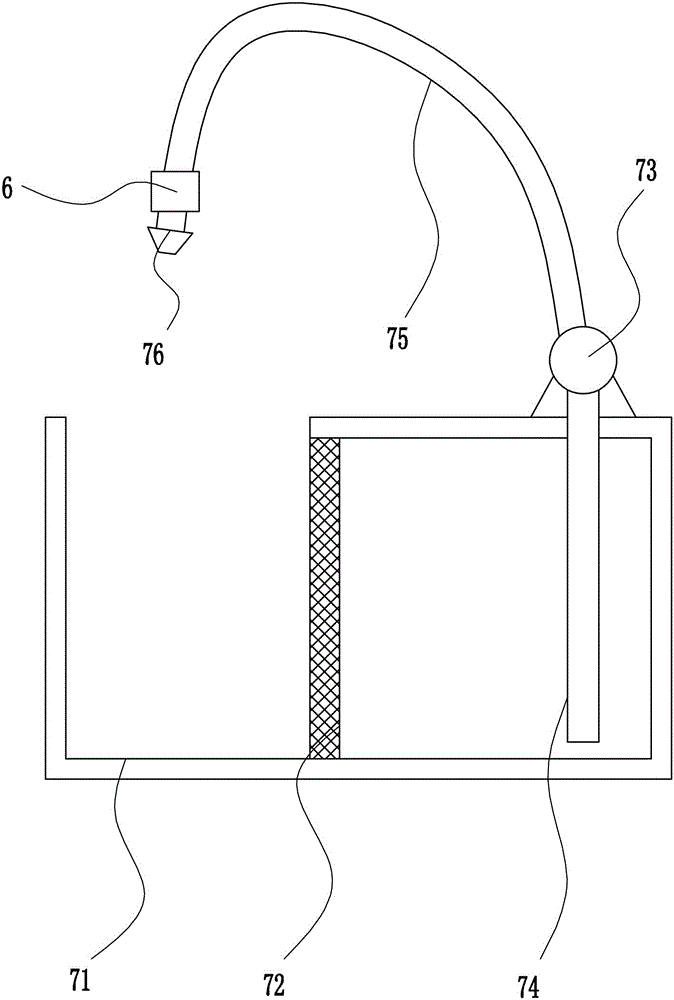

[0033] A kind of pipe cutting equipment for water conservancy projects, such as Figure 1-8 As shown, it includes a cutting table 1, a measuring mechanism 2, a clamping mechanism 3, a cutting mechanism 4, and a cooling mechanism 7. A measuring mechanism 2 is installed on the right side of the cutting table 1, and a clamping mechanism 3 is installed on the measuring mechanism 2. A cutting mechanism 4 is installed on the upper left side in the middle of the table 1, and a cooling mechanism 7 is installed on the left side of the bottom of the cutting table 1.

Embodiment 2

[0035] A kind of pipe cutting equipment for water conservancy projects, such as Figure 1-8 As shown, it includes a cutting table 1, a measuring mechanism 2, a clamping mechanism 3, a cutting mechanism 4, and a cooling mechanism 7. A measuring mechanism 2 is installed on the right side of the cutting table 1, and a clamping mechanism 3 is installed on the measuring mechanism 2. A cutting mechanism 4 is installed on the upper left side in the middle of the table 1, and a cooling mechanism 7 is installed on the left side of the bottom of the cutting table 1.

[0036] The measuring mechanism 2 includes a first slide rail 21, a first slide block 22, a first locking tooth 23, a second locking tooth 24, a scale line 25, a spring 27 and a pressing piece 28, and the right side of the cutting table 1 is equipped with a first Slide rail 21, first slide rail 21 is provided with first slide block 22, first slide rail 21 top two sides are provided with first locking tooth 23, first slide blo...

Embodiment 3

[0038] A kind of pipe cutting equipment for water conservancy projects, such as Figure 1-8 As shown, it includes a cutting table 1, a measuring mechanism 2, a clamping mechanism 3, a cutting mechanism 4, and a cooling mechanism 7. A measuring mechanism 2 is installed on the right side of the cutting table 1, and a clamping mechanism 3 is installed on the measuring mechanism 2. A cutting mechanism 4 is installed on the upper left side in the middle of the table 1, and a cooling mechanism 7 is installed on the left side of the bottom of the cutting table 1.

[0039] The measuring mechanism 2 includes a first slide rail 21, a first slide block 22, a first locking tooth 23, a second locking tooth 24, a scale line 25, a spring 27 and a pressing piece 28, and the right side of the cutting table 1 is equipped with a first Slide rail 21, first slide rail 21 is provided with first slide block 22, first slide rail 21 top two sides are provided with first locking tooth 23, first slide b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com