Pipeline cutting device

A pipe cutting and pipe technology, applied in the field of pipe cutting devices, can solve the problems of troublesome pipe cutting, high cutting cost, difficult pipe cutting, etc., and achieve the effects of low cost, simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

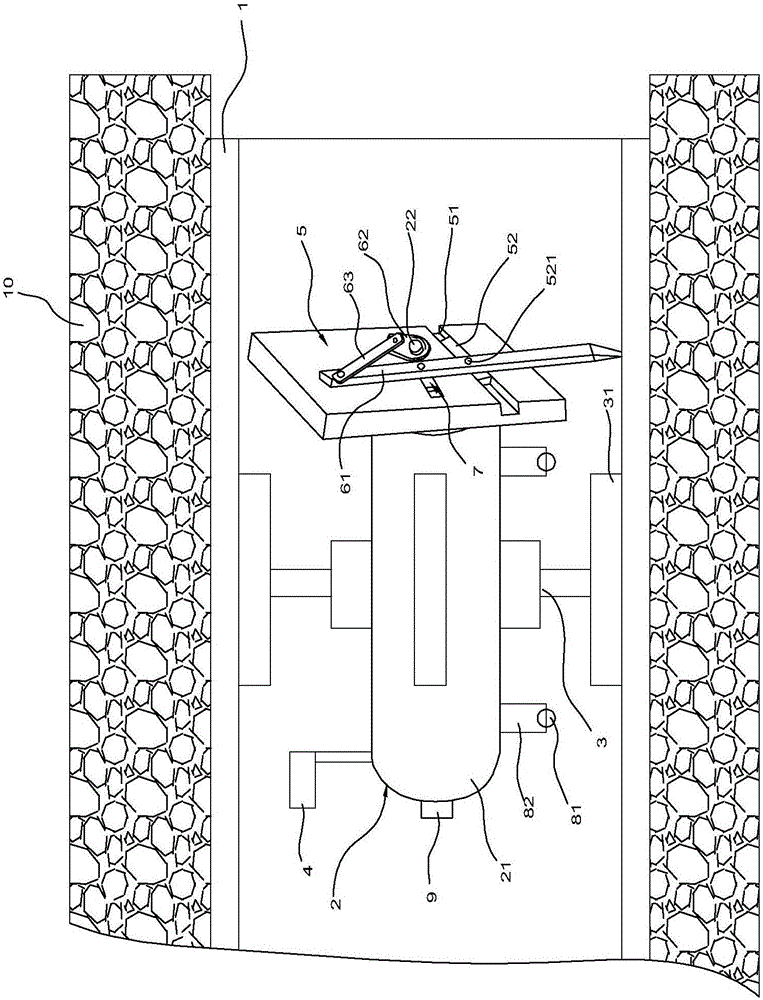

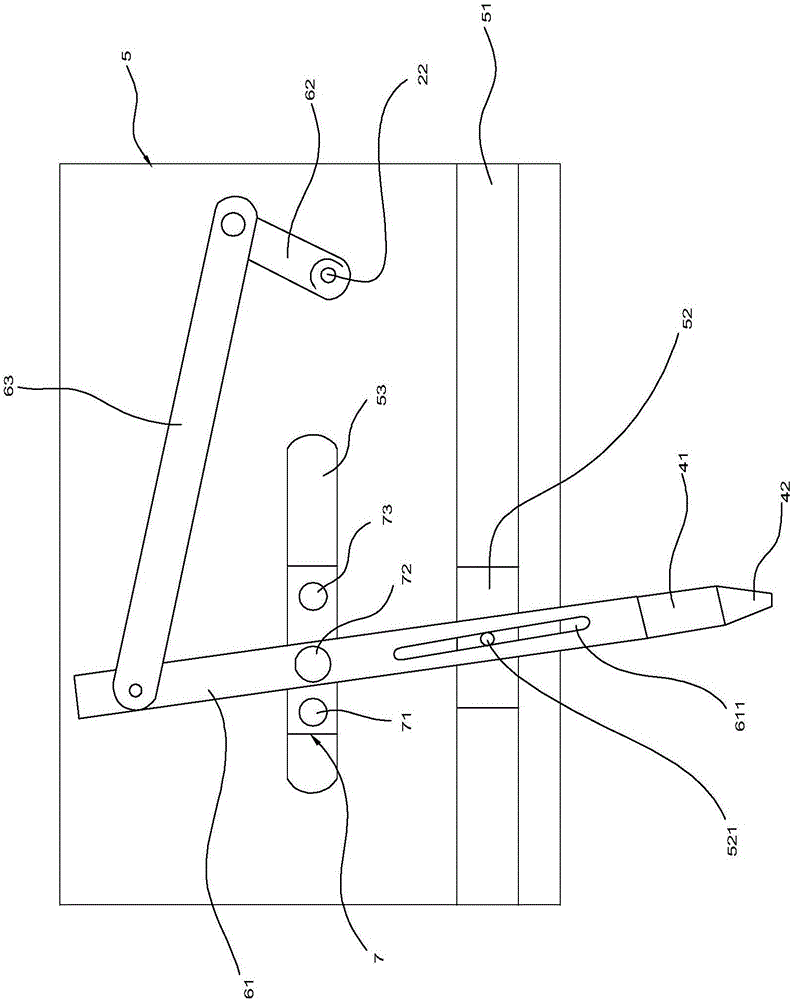

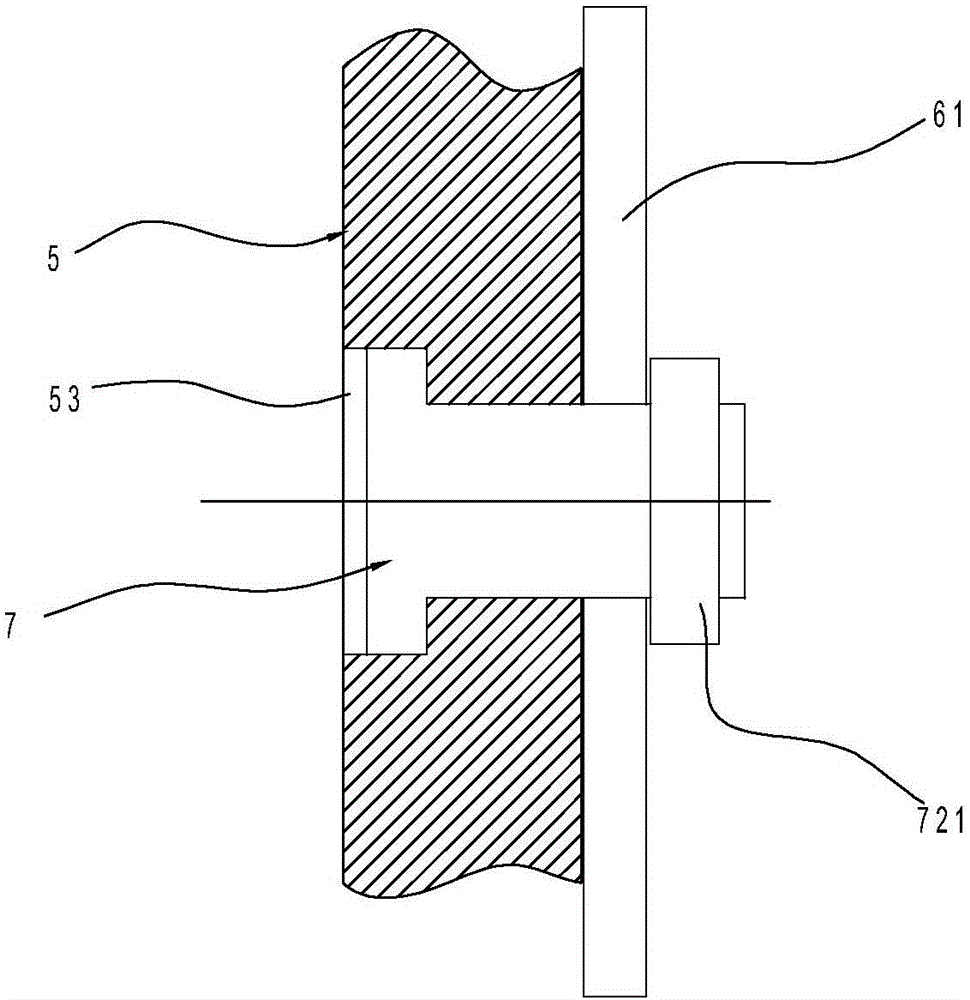

[0014] like Figures 1 to 5 As shown, the pipe cutting device in this implementation includes a drive motor 2, a support cylinder 3, a support block 31, a pushing mechanism 8, a fixed plate 5, a first connecting rod 61, a second connecting rod 62, a connecting rod 63, Lock slider 7, slide block 52, cutting cylinder 42, cutting knife 41 and controller.

[0015] Wherein, the driving motor 2 is placed in the pipeline 10, the driving motor 2 includes a body 21 and an output shaft 22, a plurality of support cylinders 3 are arranged on the outer wall of the body 21, and the cylinder body of each support cylinder 3 is fixedly arranged on the body 21, the outer end of the piston rod of each support cylinder 3 is provided with a support block 31, and the lower part of the body 21 is provided with a push mechanism 8 that pushes the drive motor 2 to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com