Automatic paint spraying device of pier

A technology for automatic painting and bridge piers, which is used in spraying devices, bridges, bridge maintenance, etc. It can solve the problems of high construction risk and low painting efficiency, and achieve the effect of uniform paint film thickness, high paint utilization rate and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

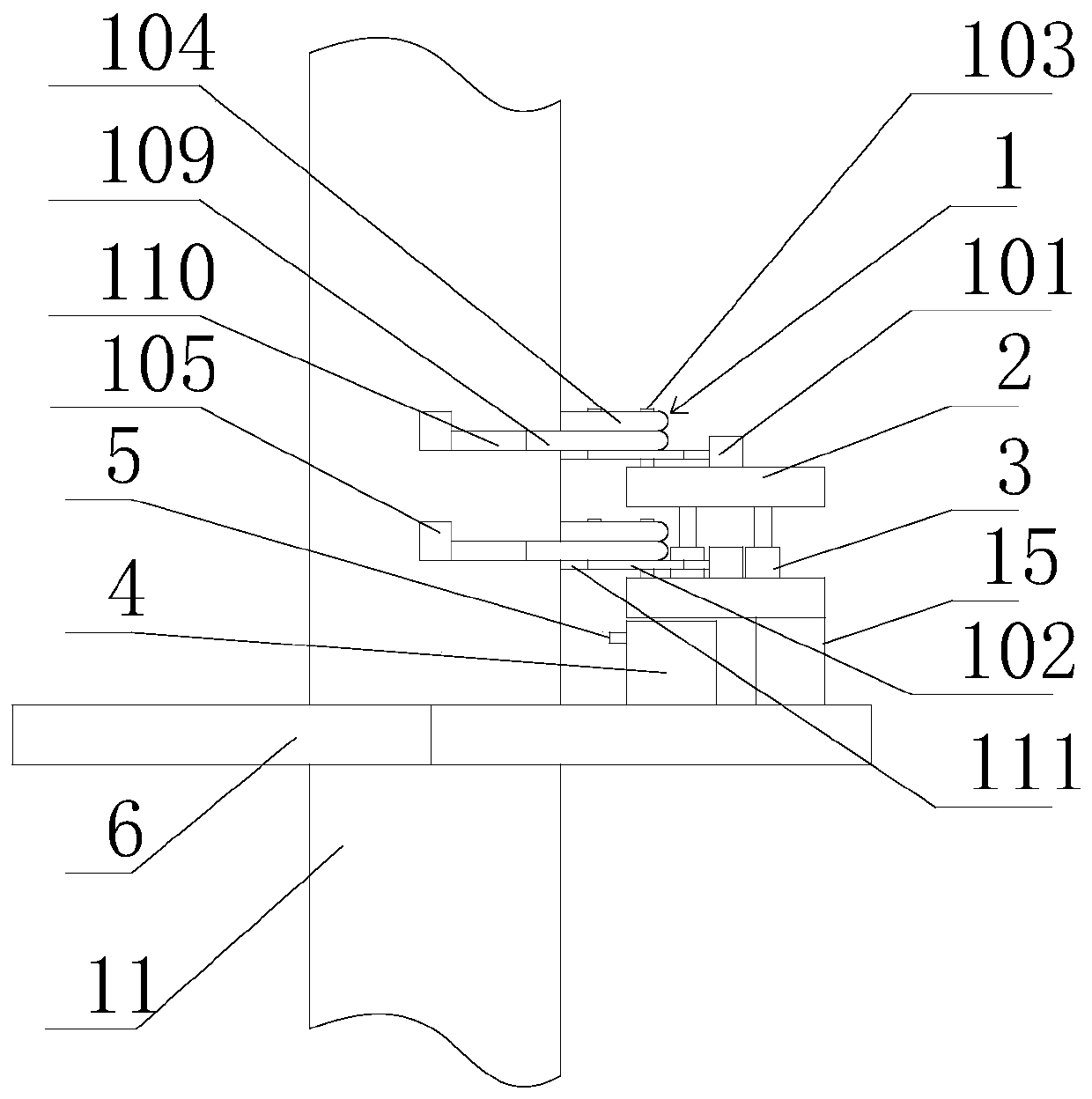

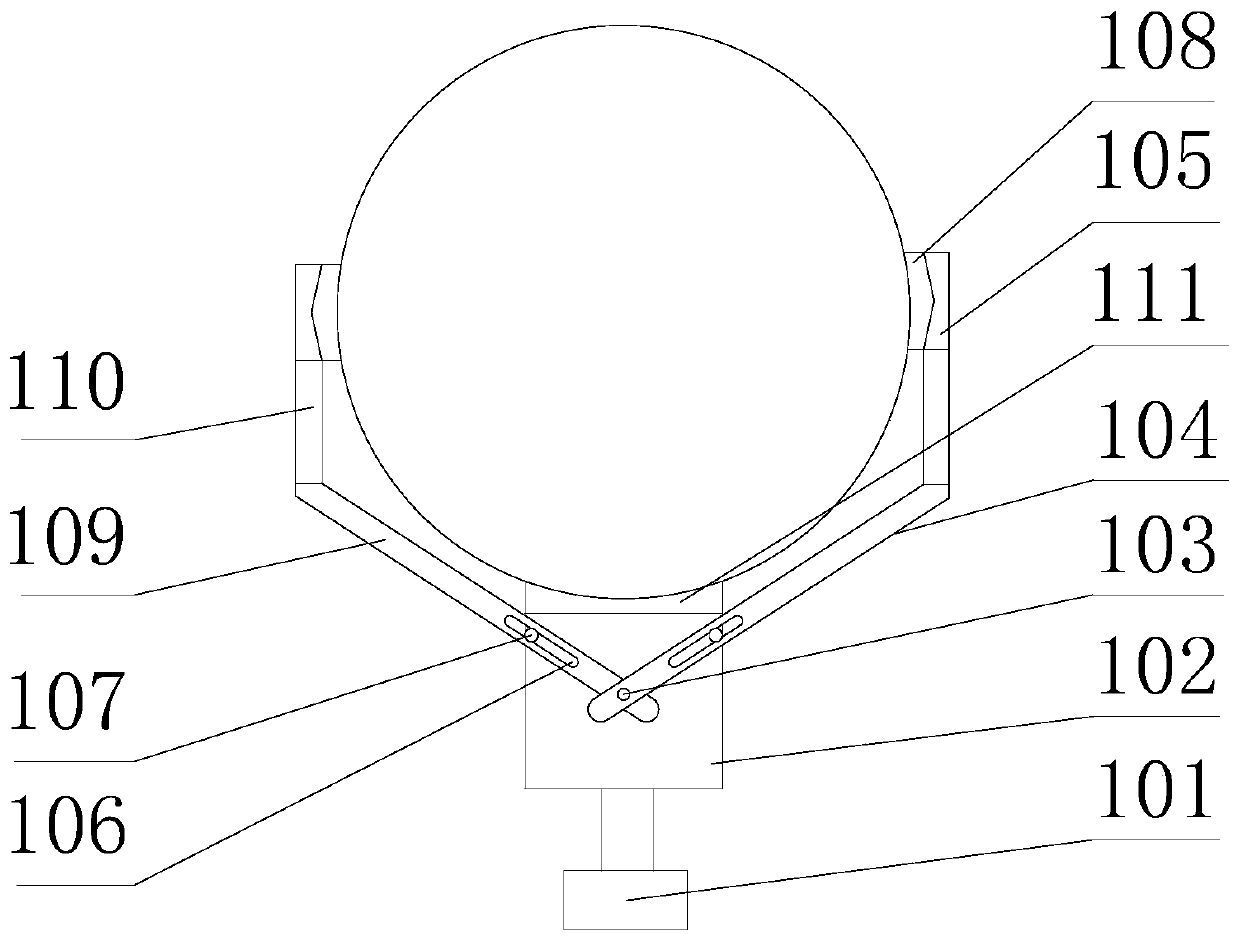

[0027] Such as figure 1 with figure 2 As shown, this embodiment includes a sprayer 4, two clamping assemblies 1, two bearing plates 2 and at least one lifting drive cylinder 3, the lifting drive cylinder 3 is vertically arranged, and the two bearing plates 2 are coaxially arranged , the lift drive cylinder 3 is fixed on one of the load plates 2, and the output end of the lift drive cylinder 3 is connected to the other load plate 2, the sprayer 4 is fixed on the load plate 2 below, and the two described The clamping components 1 are respectively fixed on the upper surfaces of the two bearing plates 2, and the clamping components 1 are used to clamp on the pier 11 to fix the bearing plate 2 and the spraying machine 4; when in use, one of the clamping components 1 is closed and clamped On the pier 11, another clamping component 2 is released, and the lifting drive cylinder 3 is controlled to expand and contract, so that the loosened clamping component 2 can be lifted and lowere...

Embodiment 2

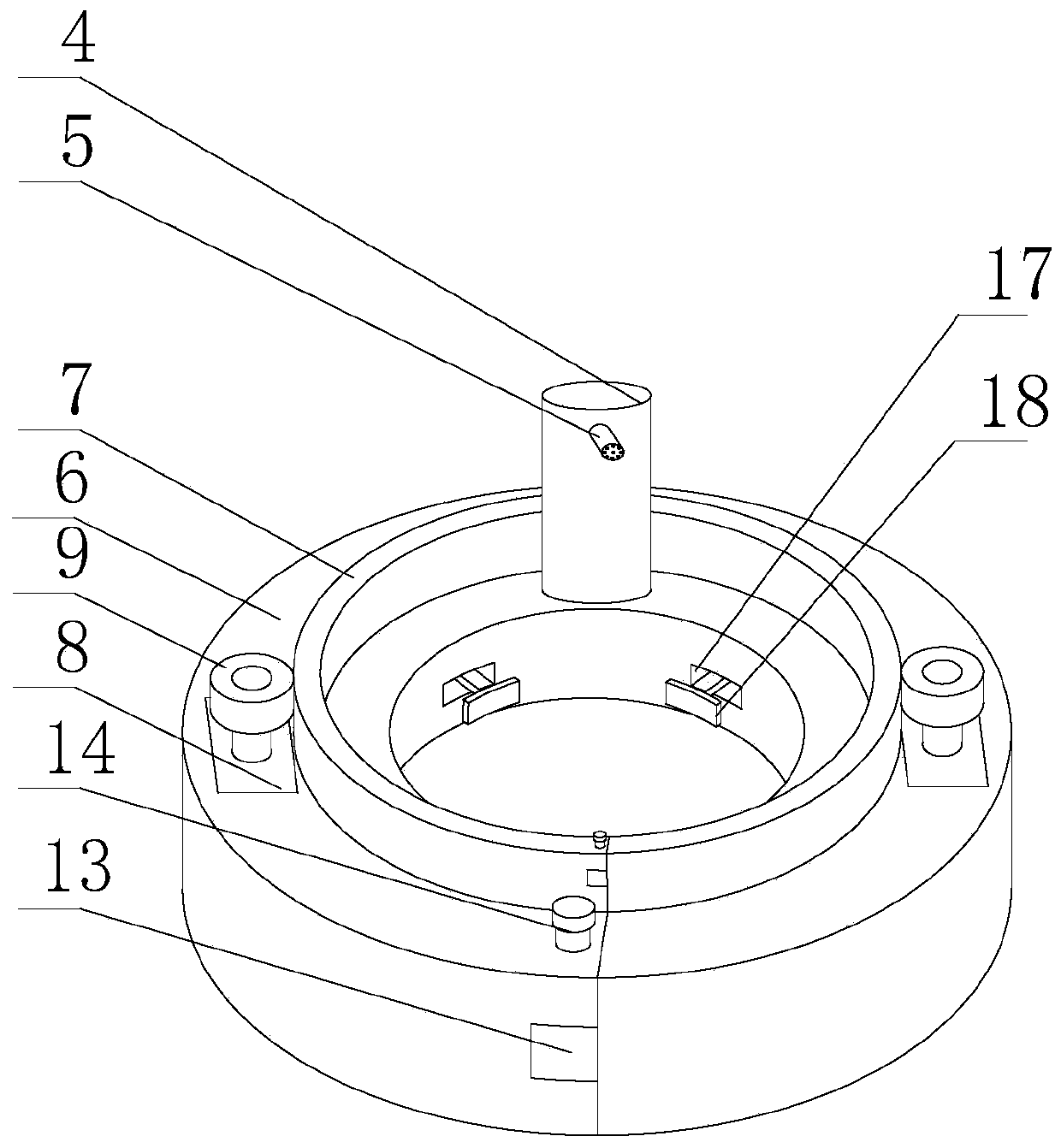

[0030] In order to enable the device to realize ring-shaped painting of the pier 11, the present embodiment is further limited on the basis of embodiment 1; as image 3 with Figure 4 As shown, two semi-annular plates 6 are also included in the present embodiment, wherein one semi-annular plate 6 is connected to any one of the bearing plates 2 through a connecting block 15, and the end surface of each semi-annular plate 6 is provided with a first protrusion. 13, the end face of the other semicircular plate 6 is provided with a first groove, the first protrusion 13 is matched with the first groove, and the first protrusion 13 is provided with a first threaded hole. A groove side wall is provided with the second threaded hole, and the stop bolt 14 passes through the first threaded hole and the second threaded hole to fix the two semicircular ring plates 6 to form a full circular annular plate; The upper surface of the ring plate 6 is provided with a semicircular trapezoidal gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com