Multi-joint omnidirectional motion pipeline robot

A pipeline robot and multi-joint technology, applied in the field of robotics, can solve the problems of walking foot gait planning and the difficulty of coordinated motion control between joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

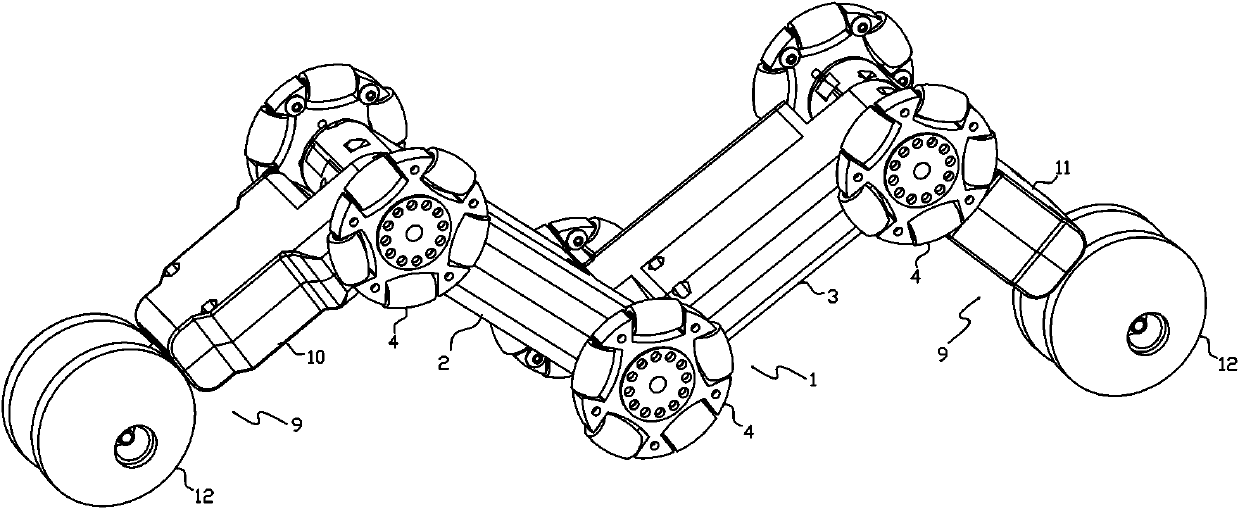

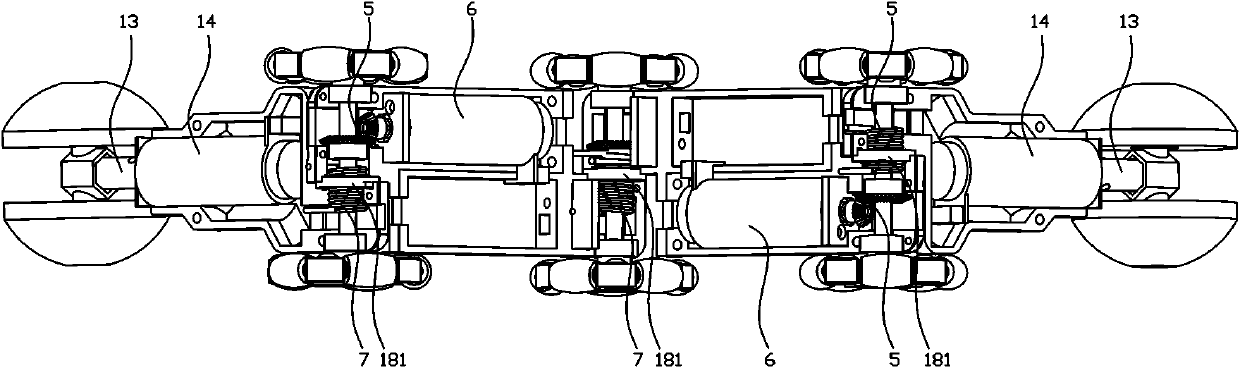

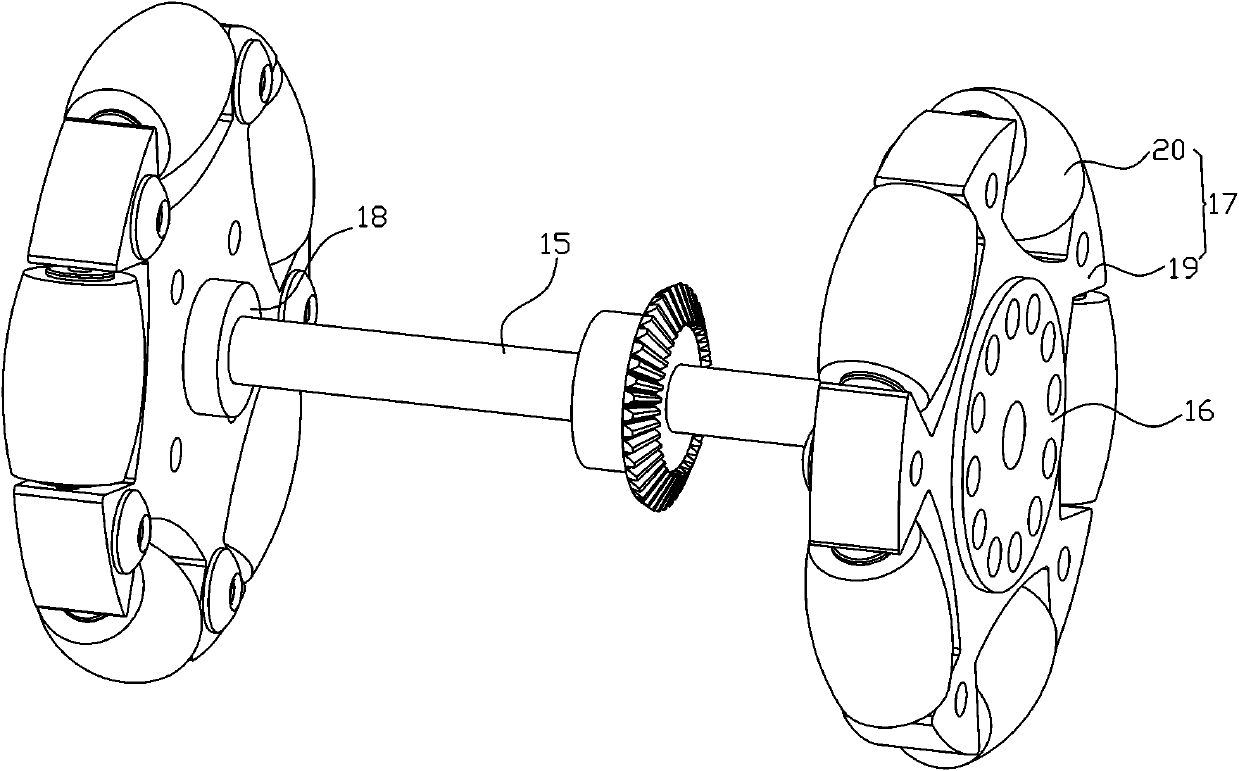

[0038] Such as Figure 1-8 As shown, the multi-joint omnidirectional motion pipeline robot of the present invention includes an intermediate joint 1 and a guide joint 9 . The intermediate joint 1 is mainly composed of the first shell 2 and the second shell 3 hinged through the inner ends, the hinges of the first shell 2 and the second shell 3 and the first shell 2, The outer ends of the second housing 3 are respectively provided with wheel assemblies 4 . The wheel assemblies 4 on the outer ends of the first housing 2 and the second housing 3 are respectively connected to the driving motor 6 through the bevel gear pair 5 . Described bevel gear pair 5 is made up of active conical wheel and passive conical wheel that mesh with each other, and described active conical wheel is connected with driving motor 6, and described passive conical wheel is fixed with the axle of described wheel assembly 4. couplet. A torsion spring 7 is provided between the first housing 2 and the second...

Embodiment 2

[0049] Such as Figure 9 As shown, the multi-joint omnidirectional motion pipe robot of the present invention, between the first shell 2 and the second shell 3, between the third shell 10 and the first shell 2, the fourth Between the housing 11 and the second housing 3 there are tension springs 8 respectively, and the tension springs 8 are fixedly connected to the adjacent housings. The rest of the structure is the same as the multi-joint omnidirectional motion pipeline robot described in Embodiment 1. The robot finally forms a W-shaped multi-joint configuration structure through the tension spring 8 .

[0050] Further, the first shell 2 , the second shell 3 , the third shell 10 , and the fourth shell 11 are all provided with expansion joints 24 . The expansion joint 24 realizes the change of the length of the pipeline robot under the drive of the linear motor. The structure of the expansion joint 24 is a known technology, so it will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com