Improved installing and manufacturing technology for snow throwing push shovel

A manufacturing process and technology for snow throwing ports, which are applied in the field of installation and manufacturing process of snow throwing shovels, can solve the problems of single production and manufacturing, cannot guarantee product quality requirements and product functions, etc., and meet strict installation requirements and strong synchronization technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

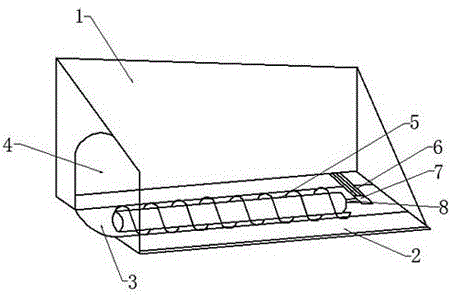

[0009] The present invention will be further described below in conjunction with accompanying drawing.

[0010] Taking the improved snow-throwing push shovel as an example, use oxygen welding to cut out a rectangular opening and trim the edge of the mouth on the bottom plate 2 of the original push shovel 1—cut out the snow-throwing opening 4 and trim the edge on the right side of the original push shovel by oxygen welding Grinding of burrs—welding the spiral concave support 3 under the rectangular opening, repairing the weld joint grinding—installing the screw 5 on the upper front end of the spiral concave support 3 close to the snow throwing port 4—installing the transmission shaft 8 at the rear end of the screw 5 on the transmission In 7—the power shaft 6 is installed on the transmission 7 side perpendicular to the transmission shaft 8—the appearance is degreased, rusted, polished, and painted—all-round inspection, dynamic inspection, and functional experiment.

[0011] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com