Manufacturing mold for chip scraping plate

A scraper and mold technology, which is applied in the direction of manufacturing tools, clamping, and supporting, can solve the problems of inability to ensure concentric holes of splicing holes, inability to fix raw materials well, and poor quality of finished products, etc. The effect of quality improvement and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

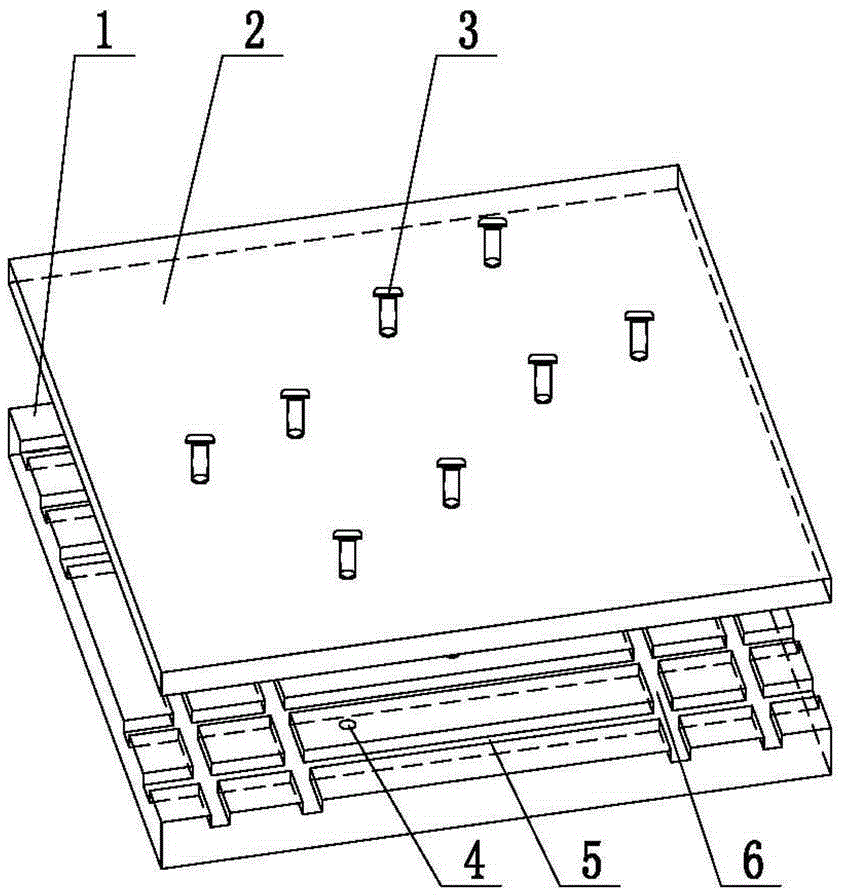

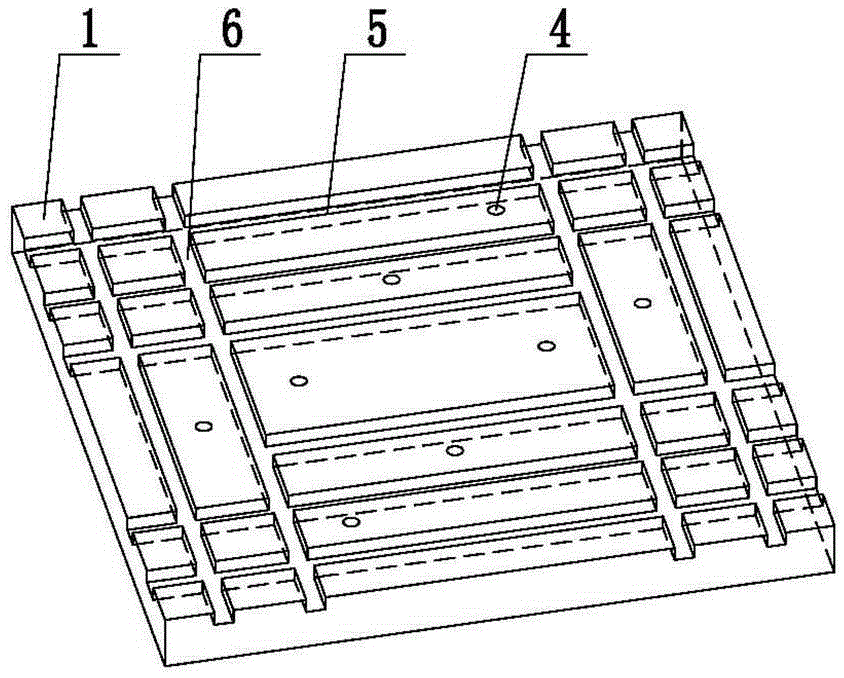

[0011] The present invention comprises a base plate 1 and a pressing plate 2, and is characterized in that: the surface of the base plate 1 is provided with transverse grooves 5 and longitudinal grooves 6, and the transverse grooves 5 and the longitudinal grooves 6 are perpendicular to each other and intersect; Connecting holes 4 corresponding to each other are provided; the pressure plate 2 and the bottom plate 1 are connected by bolts 3 in the connecting holes 4 .

[0012] Both sides of the base plate 1 are provided with two longitudinal grooves 6, and the upper and lower sides of the base plate 1 are provided with three transverse grooves 5. The longitudinal grooves 6 run through the surface of the base plate 1; The two transverse grooves 5 on the upper and lower sides are arranged to penetrate the surface of the bottom plate 1; the third transverse groove 5 on the upper side of the bottom plate 1 intersects with two longitudinal grooves 6 on the left side of the bottom plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com