Plate cylinder cooling device for gravure printing press and cooling method thereof

A gravure printing machine and printing plate cylinder technology, which is applied to printing machines, rotary printing machines, general parts of printing machinery, etc., can solve unresolved technical problems and other problems, and achieve the effects of reasonable design, stable hue, and stable stroke thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

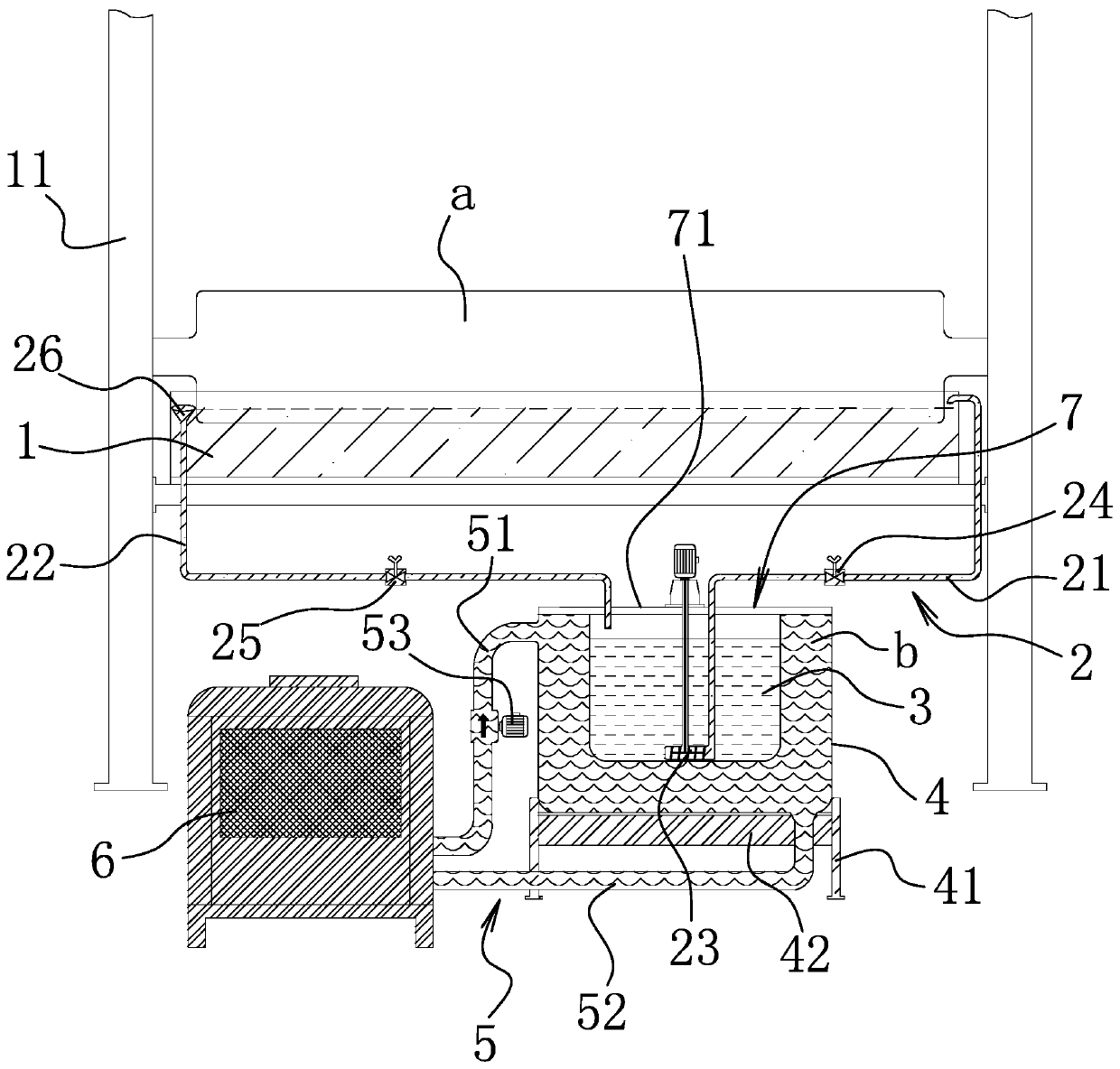

[0028] Such as figure 1 As shown, the plate cylinder cooling device of the gravure printing machine comprises a horizontally arranged ink tank 1 and a part of the plate cylinder is immersed in the ink in the ink tank 1, and the ink tank 1 is fixed on the frame 11 of the gravure printing machine; The two ends of a are worn on the frame 11 of the gravure printing machine and are rotatably connected with the frame 11 of the gravure printing machine.

[0029] A positioning frame is arranged on the frame 11 of the gravure printing machine, and the ink tank 1 is fixed on the positioning frame through several connecting feet, and the ink tank 1 is located below the printing plate cylinder a. The positioning frame and the gravure printin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap