Mechanical traction device with buffer function

A mechanical traction and functional technology, applied in the direction of traction connectors, transportation and packaging, vehicle parts, etc., can solve the problems of unstable transportation of parts and components, and achieve the effects of ensuring instability, low production costs, and flexible turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

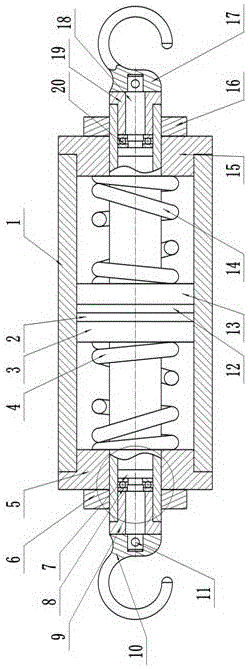

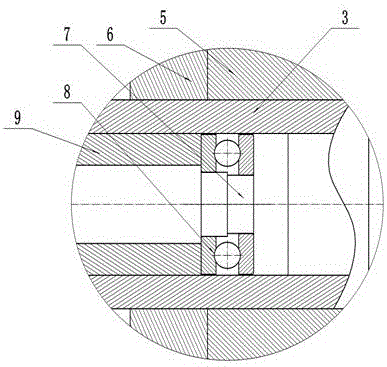

[0017] like figure 1 and figure 2 As shown, this specific embodiment adopts the following technical solutions: a mechanical traction device with a buffer function, comprising a traction housing 1, an elastic washer 1 2, a movable shaft 1 3, a spring 1 4, an end cover 1 5, Preload nut one 6, connecting shaft one 7, bearing one 8, fixing piece one 9, hook one 10, fixing screw 11, elastic washer two 12, movable shaft two 13, spring two 14, end cover two 15, preload The second nut 16, the second hook 17, the second connecting shaft 18, the first fixing piece 19 and the second bearing 20; the first end cover 5 is fixedly connected to the left end of the traction housing 1, and the first end cover 5 is movably connected with a movable shaft 1 3; the right side of the movable shaft-3 is movably connected to the inner left side of the traction housing 1, and a spring-4 is provided between the step surface on the right side of the movable shaft-3 and the right side of the end cover-5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com