Electric derailer system

A derailer, electric technology, which is applied to the equipment fixed on the track, railway car body parts, transportation and packaging, etc. problems, to achieve the effect of improving accurate and rapid feedback, facilitating overall arrangements, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

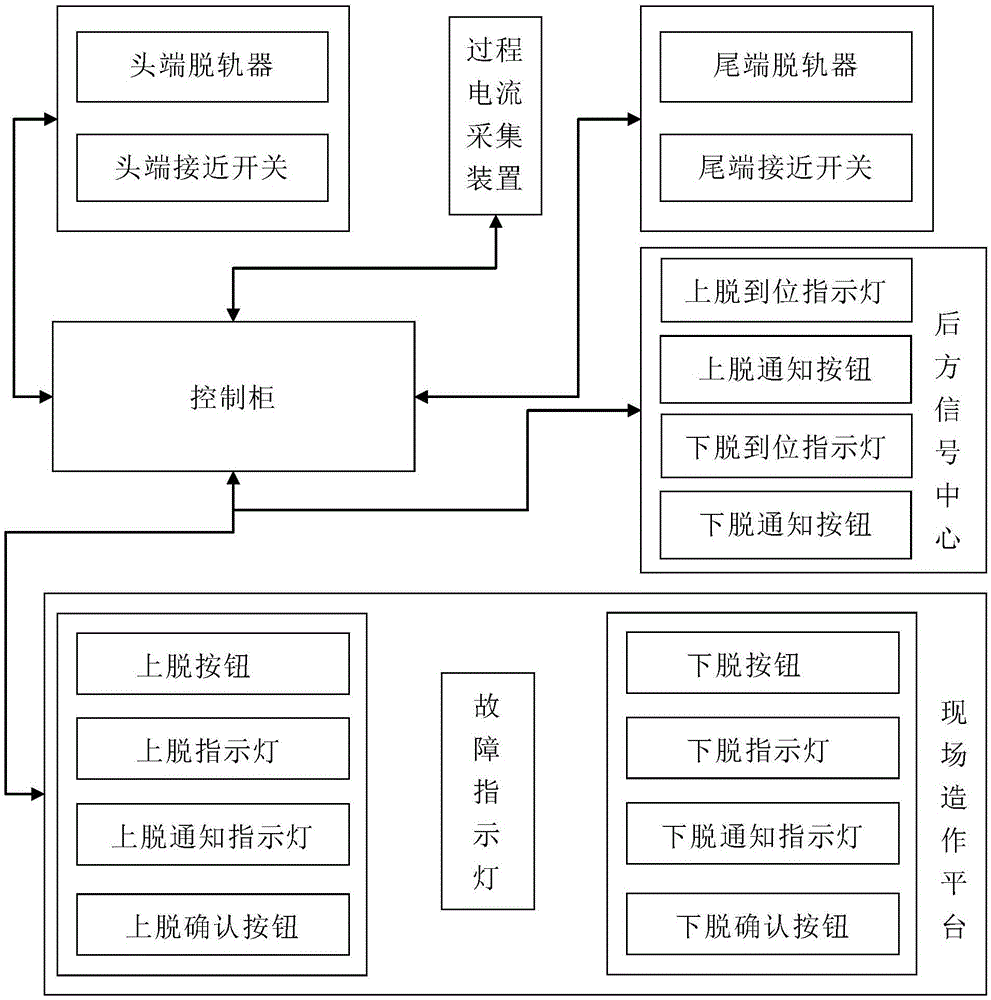

[0043] The embodiment of the present application provides an electric derailer system to solve the technical problems in the prior art that the feedback efficiency of the derailment state is low, the labor intensity of the upper and lower derailment operations is high, and the feedback of the in-position status is unreliable; the efficiency of the state feedback of the derailer is improved, and the reliability is improved. Sex, the technical effect of reducing labor intensity.

[0044] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

[0045] By establishing the derailer on the track site, the on-site operation platform in the duty room, the signal feedback and operation command structure of the signal center in the station, and the remote control structure of the derailer, the simple operation and timely and reliable signal feedback are realized.

[0046] In order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com