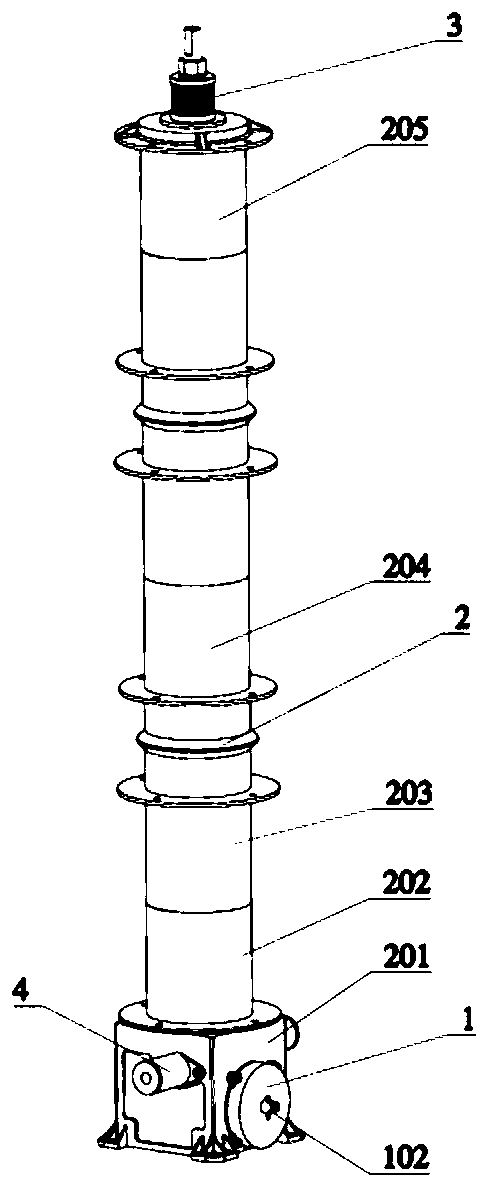

A large load-bearing hot knife type compression release device

A technology of releasing device and pressing rod, applied in the aerospace field, can solve the problems of insufficient bearing capacity, failure to deploy accessories, affecting the deployment function of the accessories, and achieve the effect of avoiding hooking, reducing unlocking power consumption and unlocking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

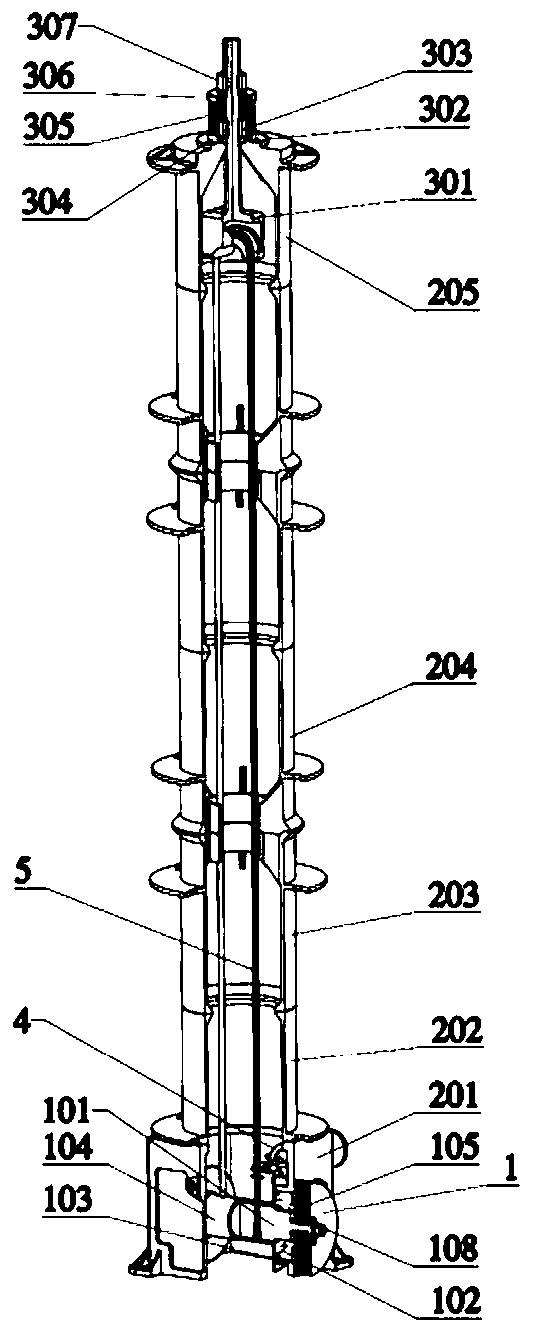

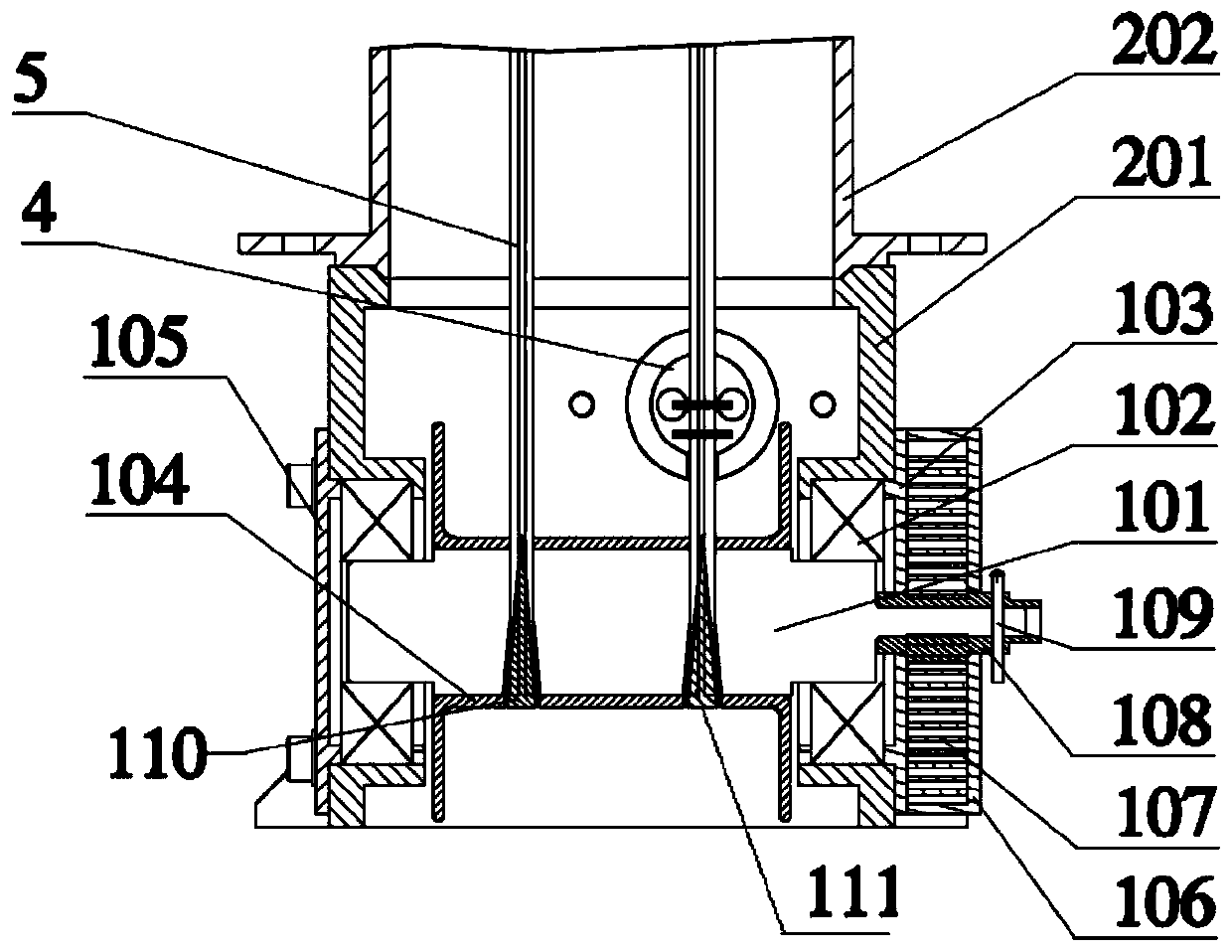

[0040] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the public implementation manners of the present invention in detail with reference to the accompanying drawings.

[0041] The invention discloses a hot-knife type compression release device with a large load, which adopts a double-segment rope, one end of the double-segment rope is connected and fixed to the reel shaft through a first tapered pin; the reel is fixed on the reel shaft, and the reel The cylinder shaft is installed on the pressing base through a pair of tapered roller bearings; at the same time, the other end of the double-section rope passes through the pressing rod, and is connected and fixed with the drum shaft through the second tapered pin. After passing the compression rod through each compression bushing and the spherical washer on the top compression bushing, use the pre-tightening force application device to tightly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com