Automatic paper receiving and aligning system for corrugated board production line

A corrugated cardboard and production line technology, applied in the manufacturing field, can solve problems such as large deviation and large consumption ratio of base paper, and achieve the effects of high speed, no product corrugation, and avoidance of misalignment deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

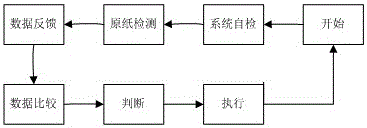

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the present invention, the present invention will be further described below in conjunction with accompanying drawing:

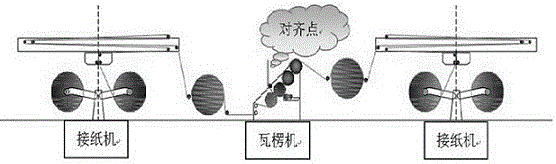

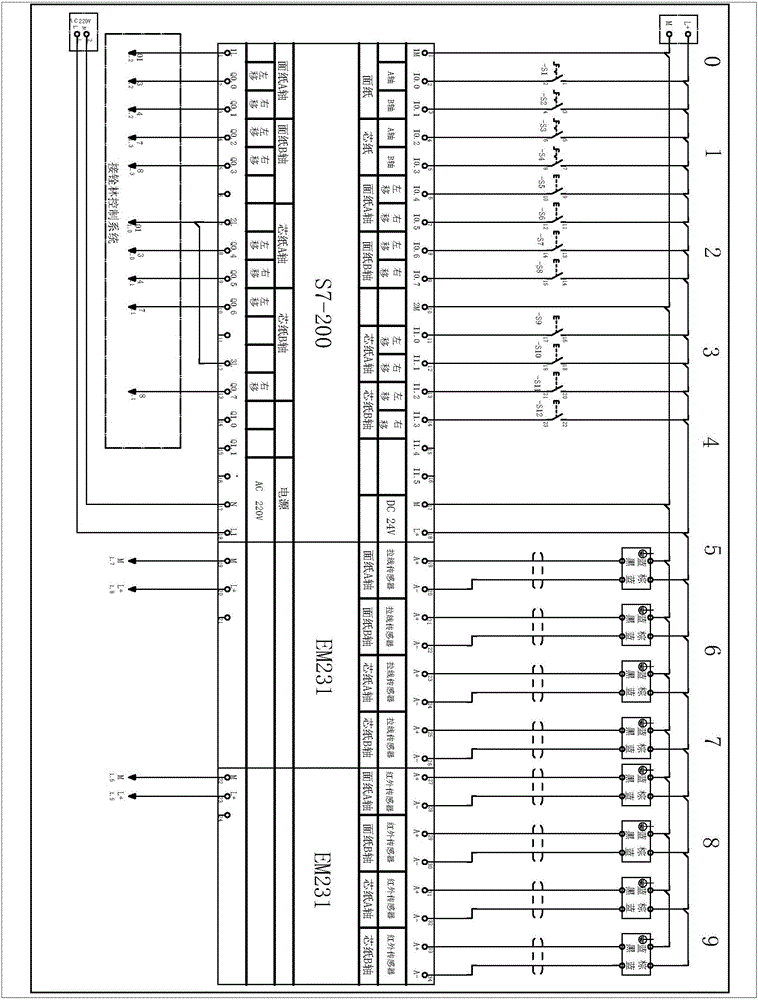

[0015] An automatic paper splicing alignment system for a corrugated cardboard production line includes a control unit, a display unit, a fixing unit, and a feedback unit; the display unit is connected to the control unit; the fixing unit functions as a fixed feedback unit; the feedback unit and the control unit connected; the control unit includes 1 PLC, 2 analog-to-digital conversion modules, and 4 transfer switches, the 1 PLC and 2 analog-to-digital conversion modules are installed in the control box, and the 4 transfer switches are installed correspondingly On the left and right paper arm operation panels of the shaftless paper holder; the display unit includes two touch screens, which play the role of display, adjustment and control, and the two touch screens are correspondingly installed on the left and right shaftle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com