Elevator rope twist eliminating device, installation device and method, and elevator device

A technology of installation device and installation method, which is applied in the field of twisted devices, can solve problems such as rope aliasing, adverse effects on the life of ropes and various pulleys, and achieve the effect of eliminating distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

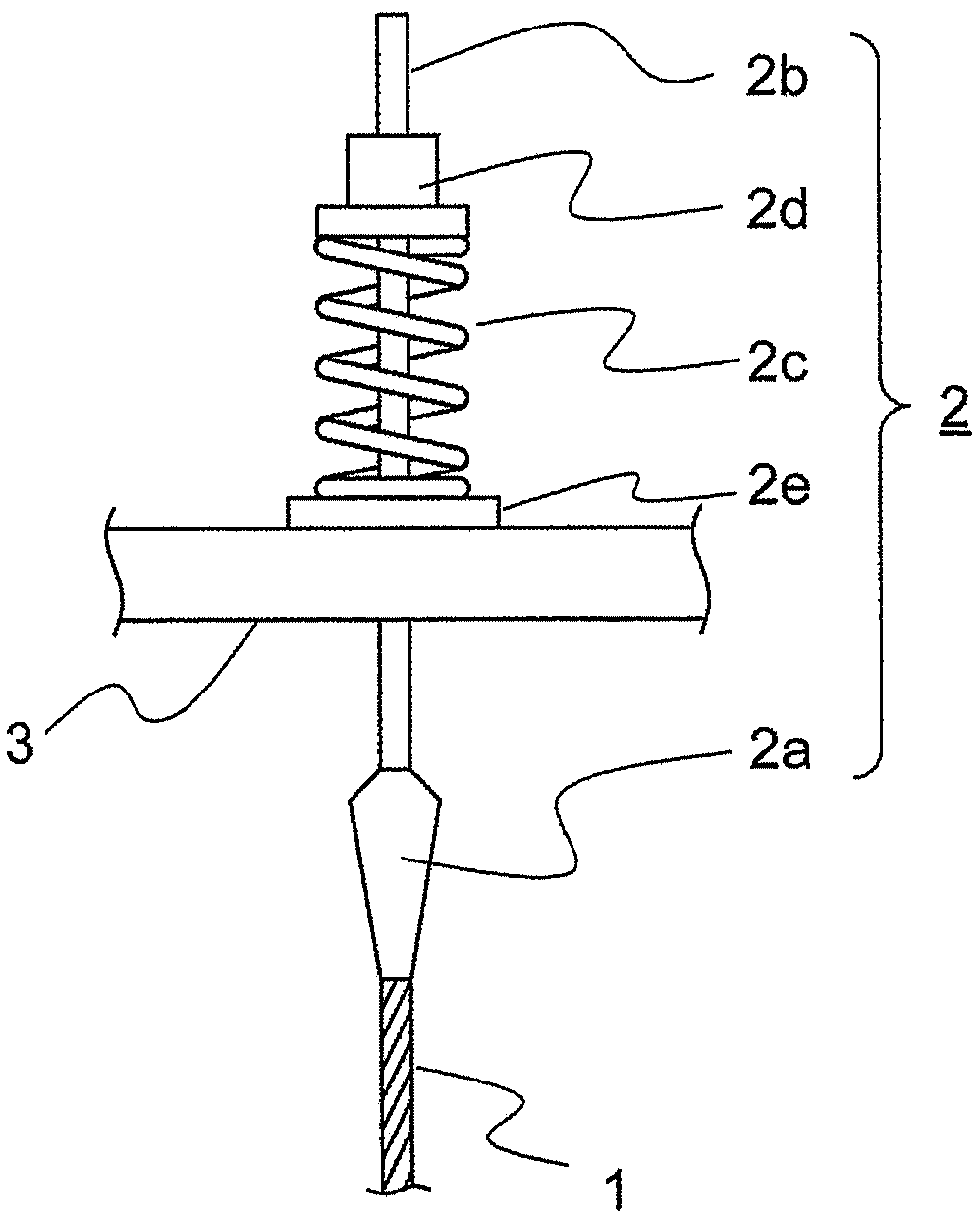

[0048] figure 1 It is a schematic front view showing an elevator during rope installation work in general elevators.

[0049] The elevator is provided with a machine room on the top of the hoistway 9 . A rope reel 5 and a traction machine 6 are arranged on the machine room ground 3 of the machine room.

[0050] A car 7 that is raised and lowered by being guided by elevator guide rails 8 extending in the vertical direction is placed on a lower portion of the machine room.

[0051] The rope installation work in this elevator is performed in the following order.

[0052] First, one end of the rope 1 fed from the rope drum 5 in the direction of the arrow A passes through the hoisting machine 6, and then hangs down toward the hoistway 9 in a U-shape as shown by the arrow B.

[0053] The rope 1 is formed by twisting single threads. When tension is applied to the rope 1, the strands of the rope 1 tend to be untied, so the rope 1 is twisted.

[0054] Therefore, as the rope 1 desc...

Embodiment approach 2

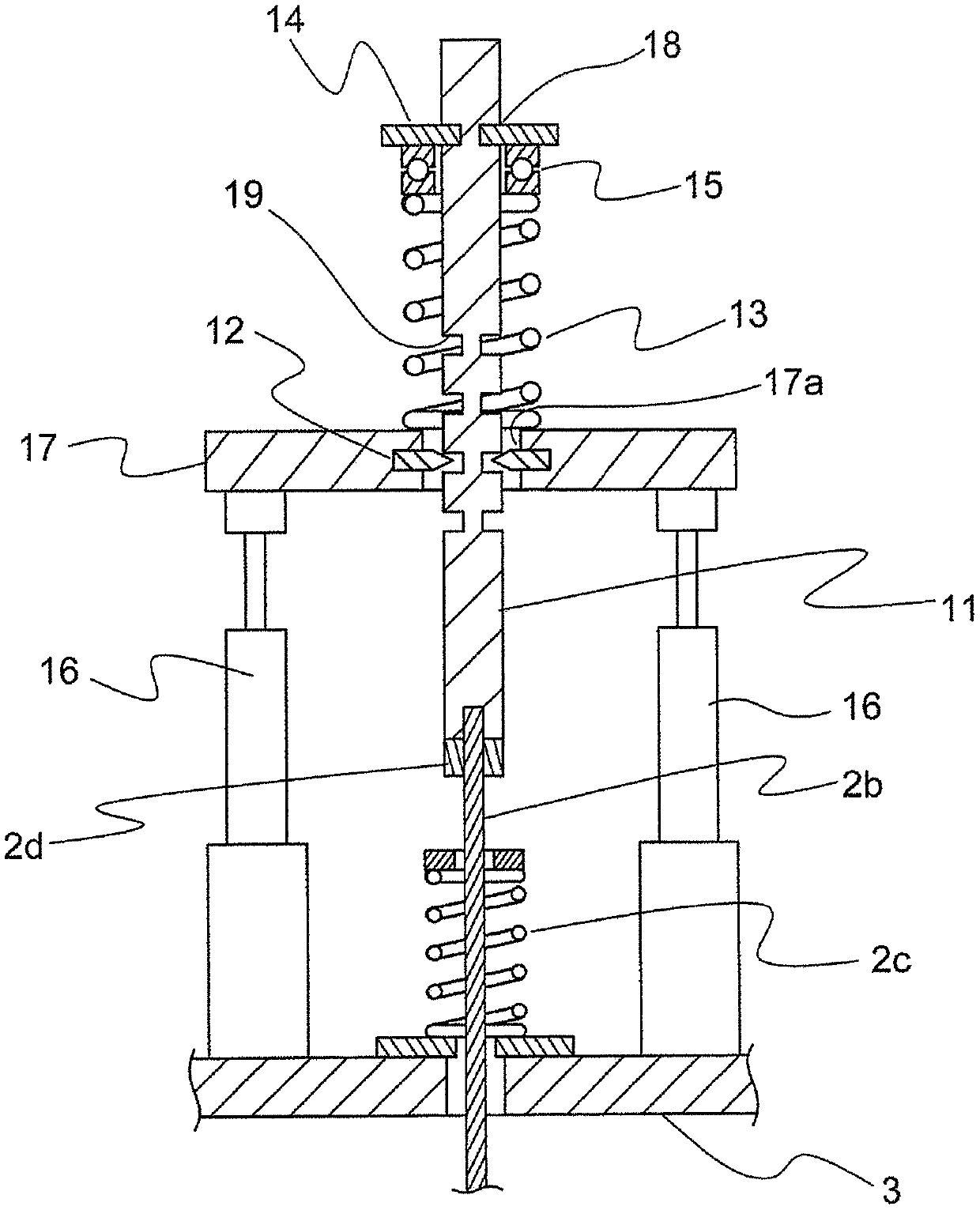

[0086] Figure 6 It is a front view showing an elevator rope twist canceling device according to Embodiment 2 of the present invention. Similar to Embodiment 1, the contraction amount of the spring is detected by the coil spring 13 as the rope tension.

[0087] The rope tension detecting unit of the elevator rope twist eliminating device according to Embodiment 2 includes: a base 17; a stopper 14 fixed to the middle portion of a rotating body 33 extending in a direction perpendicular to the base 17; The spring 13 is arranged between the stopper 14 and the base 17 .

[0088] In addition, the rope rotation unit of the elevator rope twist elimination device has: a rotating body 33 integrally connected to the end portion of the terminal rod 2b coaxially with the terminal rod 2b; rotates about the axis while moving in the up and down direction;

[0089] The above-mentioned rotation converting unit has: a rack 34 mounted on the upper peripheral surface of the rotating body 33; a w...

Embodiment approach 3

[0101] Figure 7 It is a front sectional view showing an elevator rope twist canceling device according to Embodiment 3 of the present invention.

[0102] In Embodiment 1 and Embodiment 2, the coil spring 13 is arranged coaxially with the fixing portion spring 2c of the cord fastener 2, whereby the coil spring 13 deforms in the vertical direction according to the tension of the cord.

[0103] On the other hand, in the elevator rope twist canceling device of this embodiment, there are wedges 22 provided on both sides of the rotating body 11 and horizontal springs 21 which are compression springs pressing the wedges 22 from the back, instead of the first embodiment. Coil spring 13.

[0104] In this embodiment, the rope tension detection unit has a base 17 , a stopper 14 , a wedge 22 for converting the axial movement of the rotating body 11 into a horizontal movement, and a horizontal spring 21 .

[0105] The rope rotation unit has the same rotation body 11 and rotation convers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com