A hot-dip galvanized air curtain side suction zinc fume environmental protection device

An environmental protection device, hot-dip galvanizing technology, applied in hot-dip galvanizing process, separation method, coating, etc., can solve the problems of great influence on the working environment in the workshop, poor absorption of zinc fume, etc., to facilitate cooling treatment and prevent damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

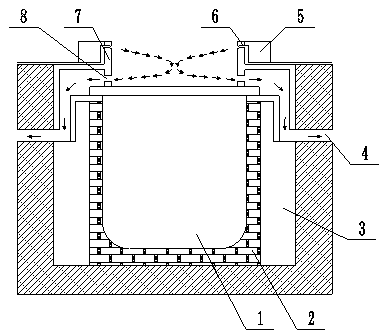

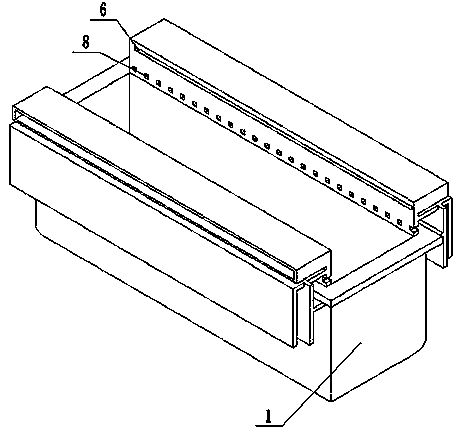

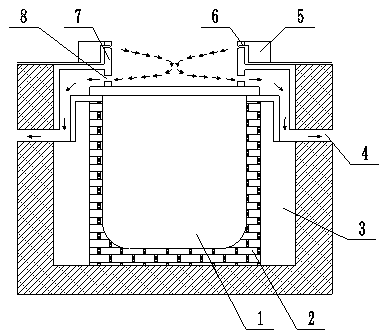

[0020] Such as figure 1 , figure 2 As shown, a hot-dip galvanized air curtain side smoke dust environmental protection device includes a zinc pot 1, zinc liquid is filled in the zinc pot 1, and a heat insulating material 2 is arranged around the zinc pot 1, and the heat insulating material 2 There is a furnace bottom observation room 3 on the periphery, which is convenient for observing the condition of the zinc pot 1;

[0021] The both sides of described zinc pot 1 pot edge are all provided with dividing plate 7, and the effect of dividing plate 7 is mainly in order to prevent the product from entering the zinc liquid from splashing, the top of described dividing plate 7 is provided with tuyere 6, and described tuyere 6 Blow out the oblique airflow. When the product enters the zinc liquid, a larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com