Multi-functional highway maintenance vehicle

A maintenance vehicle, multi-functional technology, applied in the direction of roads, roads, road surface cleaning, etc., can solve the problem of undiscovered road maintenance vehicles with multiple functions, and achieve the effect of saving procurement costs and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

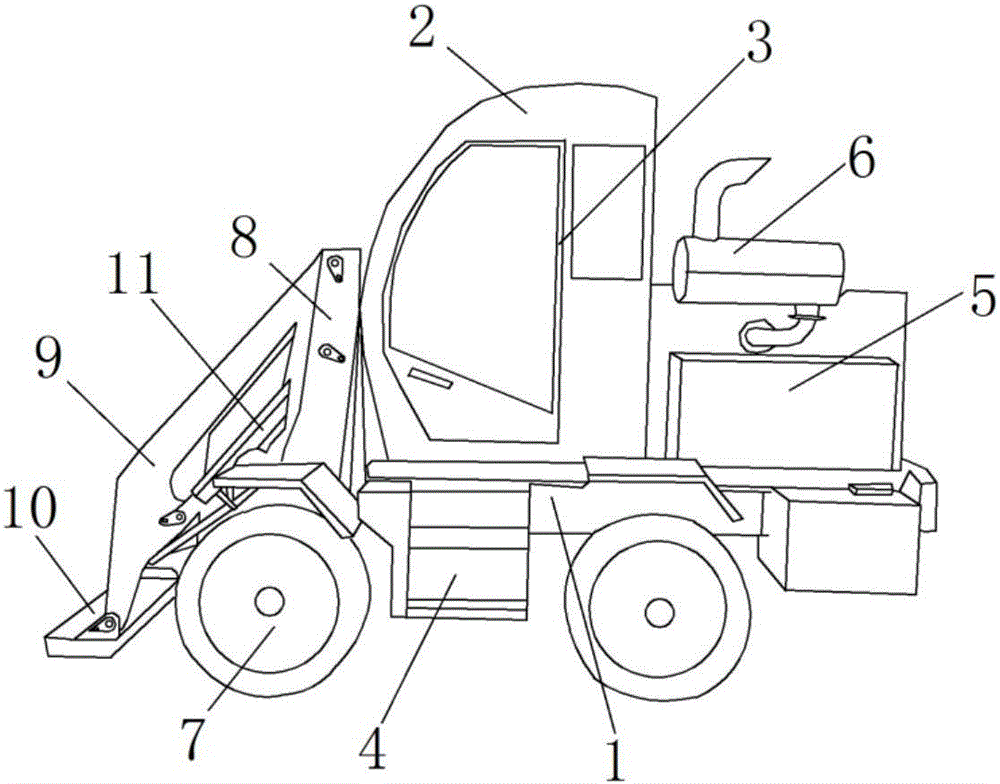

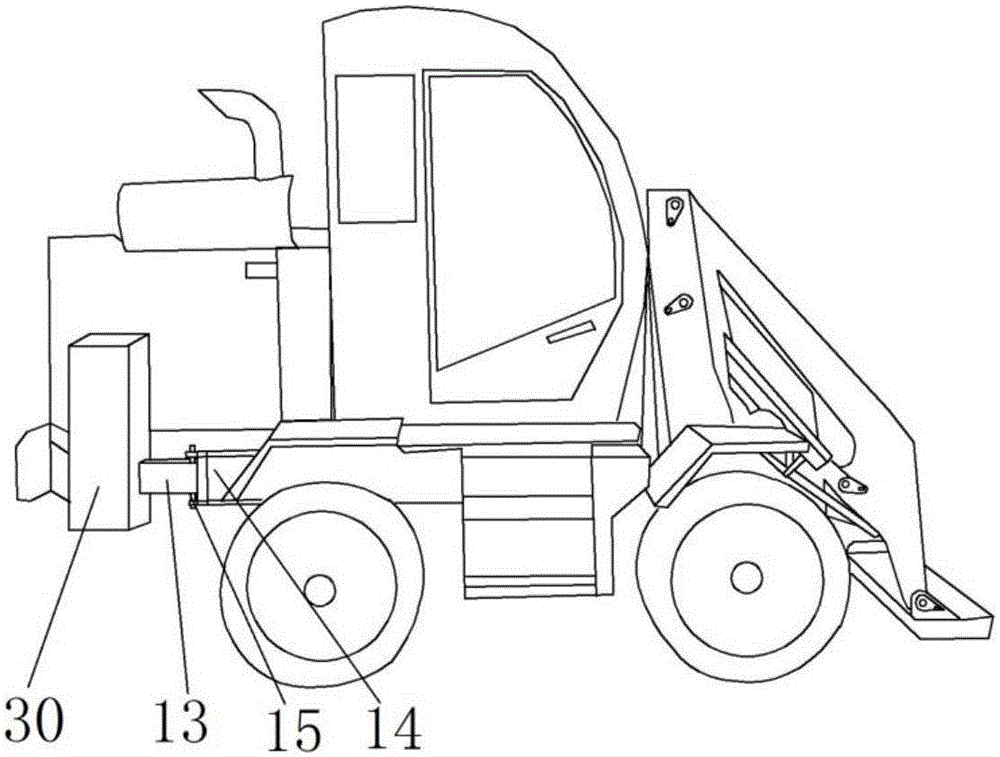

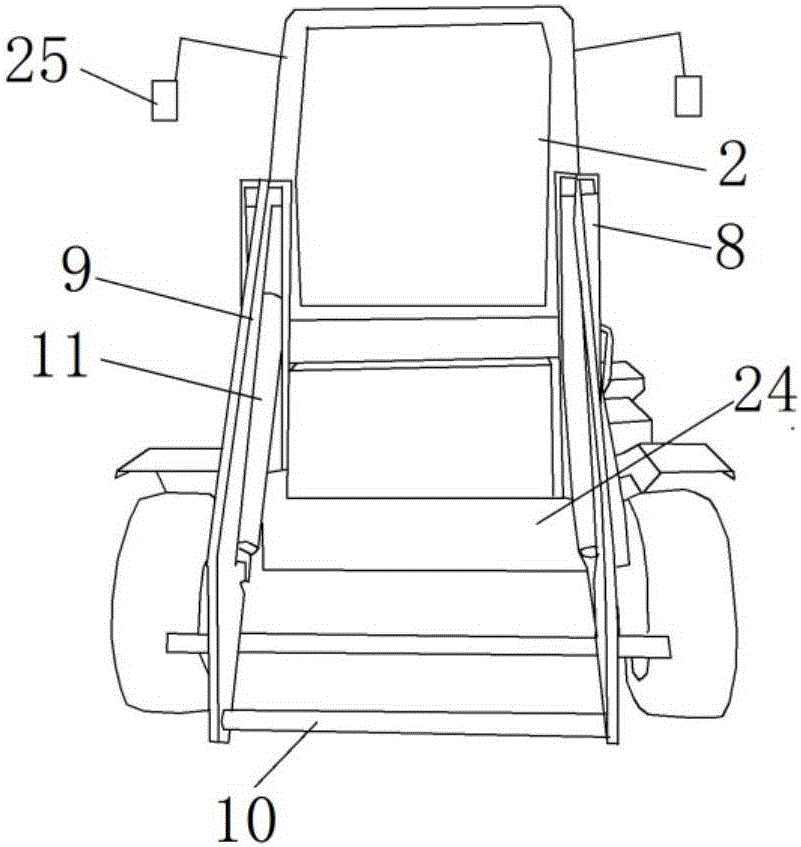

[0041] Such as Figure 1-5 Shown is the structural representation of the multifunctional road maintenance vehicle of the present invention. The multifunctional highway maintenance vehicle includes: chassis 1, wheels 7, operating room 2, door 3, car ladder 4, rearview mirror 25, diesel engine 5, air outlet 6, baffle plate 24, two support frames 8, two The supporting arm 9 , the connecting plate 10 , the first hydraulic telescopic arm 11 , the second hydraulic telescopic arm 12 , the milling machine assembly 30 , and the road roller assembly 40 , the loader assembly 50 or the sweeper assembly 60 . The operating room 2, the diesel engine 5, and the supporting frame 8 are all arranged on the chassis 1; a baffle 24 is arranged in front of the operating room 2, and two supporting frames 8 are arranged on both sides; a supporting arm 9 is respectively arranged on each supporting frame 8 The supporting arm 9 is connected to its corresponding support frame 8 through the first hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com