Automatic lifting paint brusher of electric power tower

A technology for automatic lifting and power towers, applied to towers, building types, buildings, etc., can solve problems such as incomplete cleaning, reduced painting efficiency, and affecting the service life of power towers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

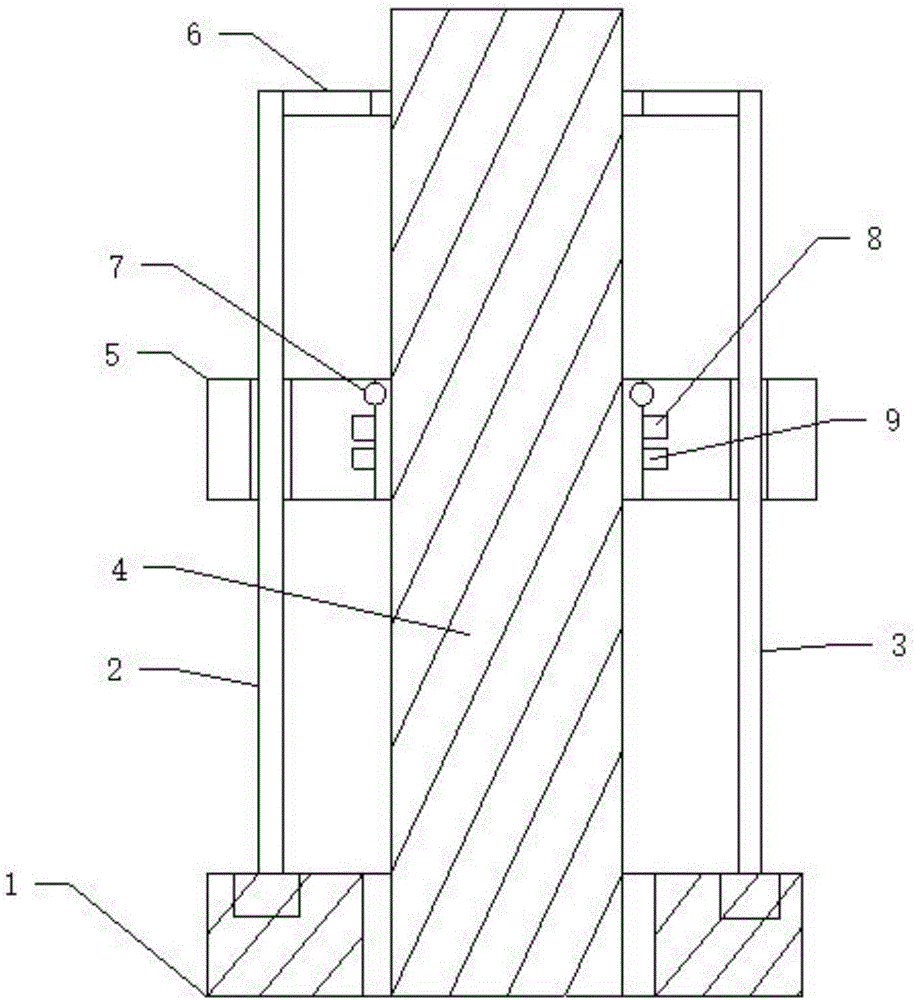

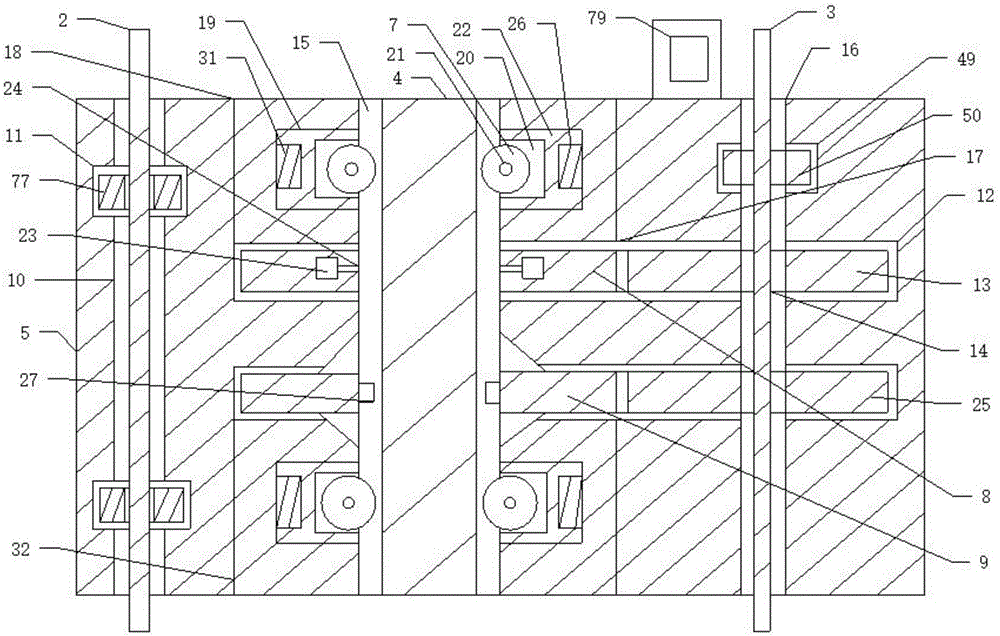

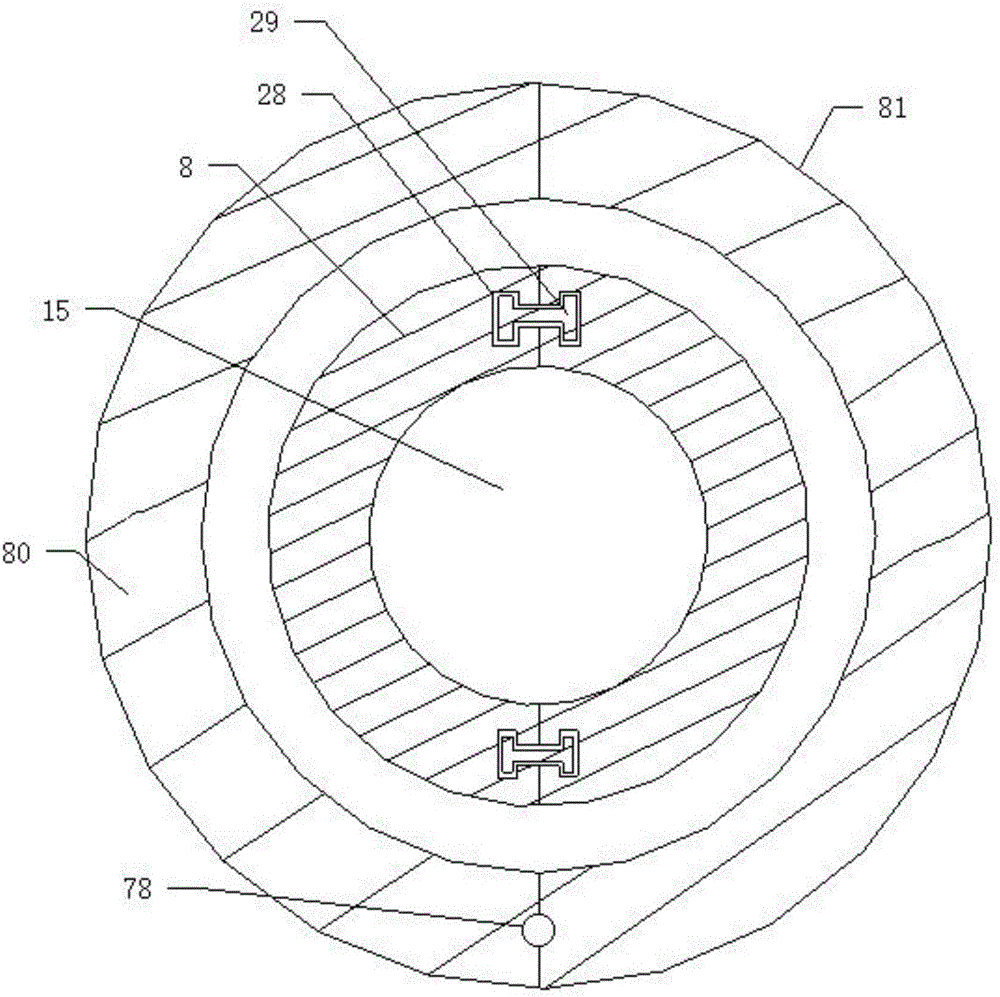

[0035] like Figure 1 to Figure 10As shown, a kind of power tower automatic lifting paint applicator comprises a fixed iron tower 4, and the bottom of described fixed iron tower 4 is provided with a fixed base 1, and described fixed base 1 is provided with a correspondingly rotating lifting threaded rod 2 and A driving rod 3 is provided with a sliding sliding brushing plate 5 on the fixed iron tower 4, and a first corresponding to the lifting threaded rod 2 and the driving rod 3 is arranged in the sliding brushing plate 5. Sliding hole 10 and a second sliding hole 16, the lifting threaded rod 2 and the driving rod 3 slide in the first sliding hole 10 and the second sliding hole 16 respectively, the sliding brushing plate 5 A first groove 11 corresponding to the first sliding hole 10 is provided inside, and a fixed slider 77 corresponding to the lifting threaded rod 2 is provided in the first groove 11. The bottom of the fixed iron tower 4 is provided with a fixed base 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com