Spring base type spherical centralizer

A spring seat and centralizer technology, applied in the direction of drill pipe, casing, drill pipe, etc., can solve problems such as secondary fishing, well diameter deformation, and affecting the life of centralizers, and achieve the effect of simple structure and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

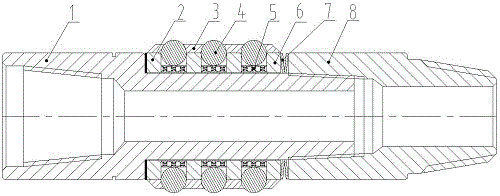

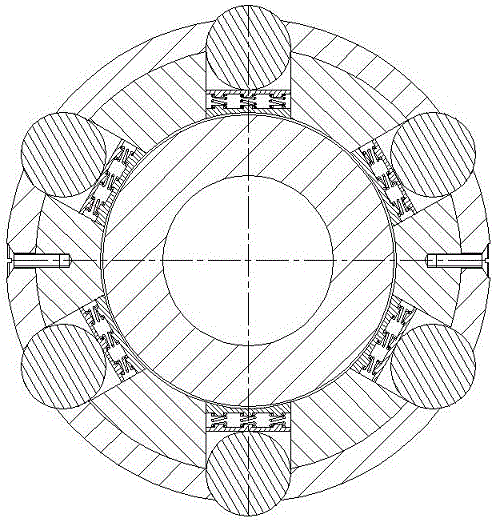

[0010] Such as figure 1 , figure 2 As shown, a spring seat type spherical centralizer of the present invention is composed of an upper joint 1, an inner centralizing sleeve 2, an outer centralizing sleeve 3, a centralizing ball 4, a spring seat 5, a compression disc spring 6 and a lower joint 7. In that: the inner centralizing sleeve 2 is an annular ring body structure, and the annular ring body is evenly opened with circular blind holes, and the inner centralizing sleeve 2 is loaded along the stepped axis of the upper joint 1; the spring seat 5 is cylindrical, and the installation In the blind hole of the inner centralizing sleeve 2, it is fixedly connected with the inner centralizing sleeve 2 by screws, and the spring seat 5 ensures that the centralizer passes through the irregular section of the borehole diameter smoothly, and at the same time, the spring seat 5 can absorb the The lateral impact force on the centralizer; the centralizing ball 4 is placed in the spring sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com