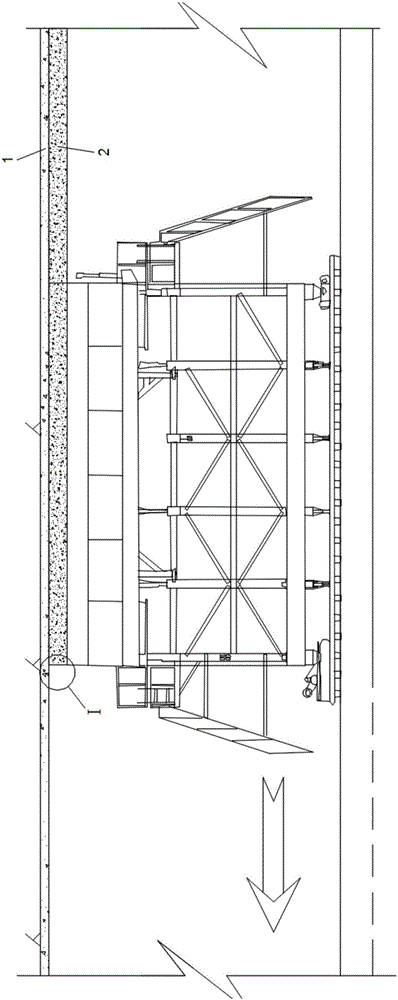

Seamless sealing formwork for tunnel secondary lining

A technology of secondary lining and plugging formwork, applied in tunnel lining, tunnel, wellbore lining, etc., can solve problems such as skew, poor sealing, damage to waterproof board or water stop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

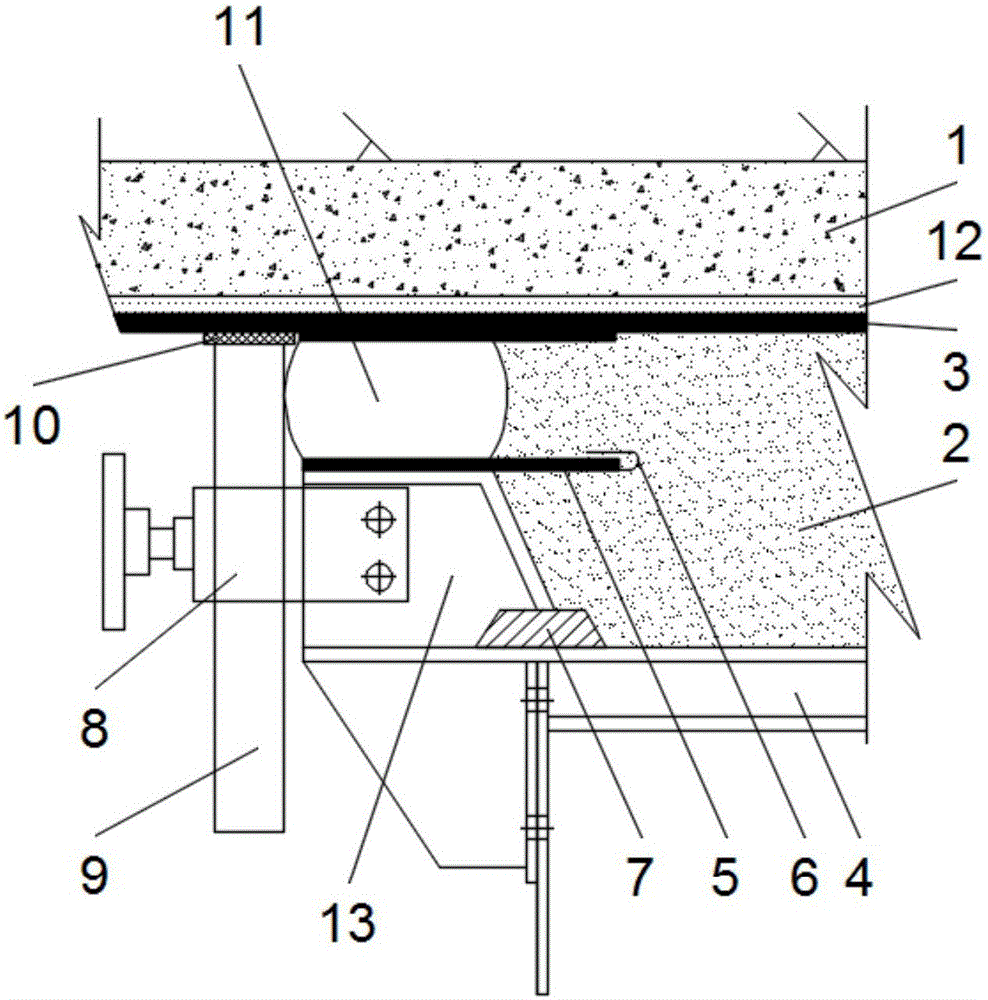

[0014] The present invention is arranged at the front end of the lining trolley, and includes a support base 13 and a rubber airbag 11, and the support base 13 and the rubber airbag 11 are circumferentially arranged at the front end of the lining trolley. A non-woven fabric 12 and a back-adhesive waterstop 3 are sequentially connected under the primary lining 1 of the tunnel. The end surface of the steel formwork 4 is connected with a supporting base 13, and above the supporting base 13, a mid-buried waterstop positioning frame 6 with the same shape as the mid-buried waterstop 5 is arranged, and the mid-buried waterstop 5 is arranged on the mid-buried waterstop. In the belt positioning frame 6, the rubber airbag 11 is arranged between the buried waterstop 5 and the back-mounted waterstop 3 and is in a squeezed state. The mid-buried waterstop 5 is sandwiched between the support base 13 and the rubber airbag 11, so it does not need to be folded at 90 degrees during the construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com