Concealed connecting structure of assembled furniture member

A connection structure and assembly technology, applied in the direction of furniture connection, connection components, pins, etc., can solve the problems of weak connection and easy shaking, improve the safety and reliability of use, eliminate gaps, and achieve firmness and stability. aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

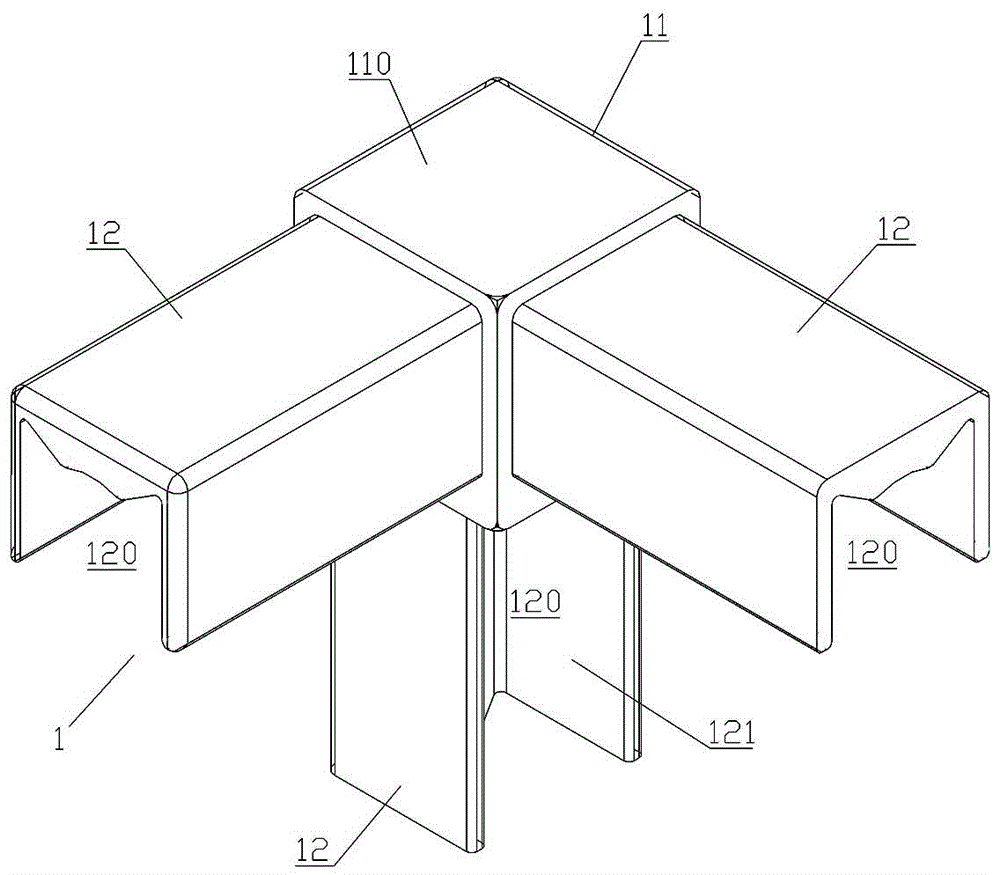

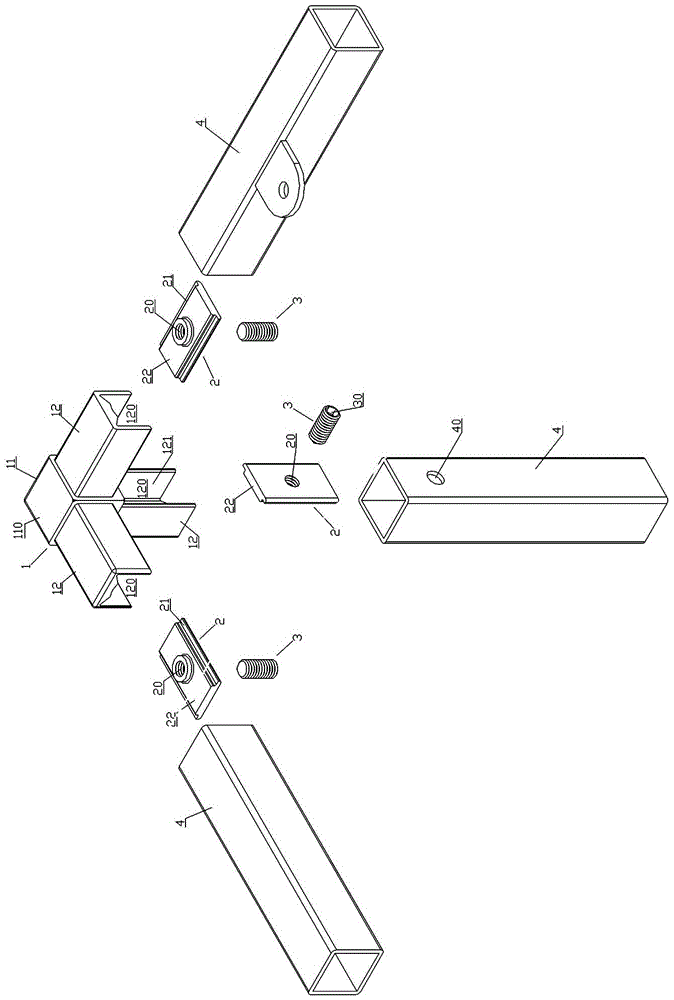

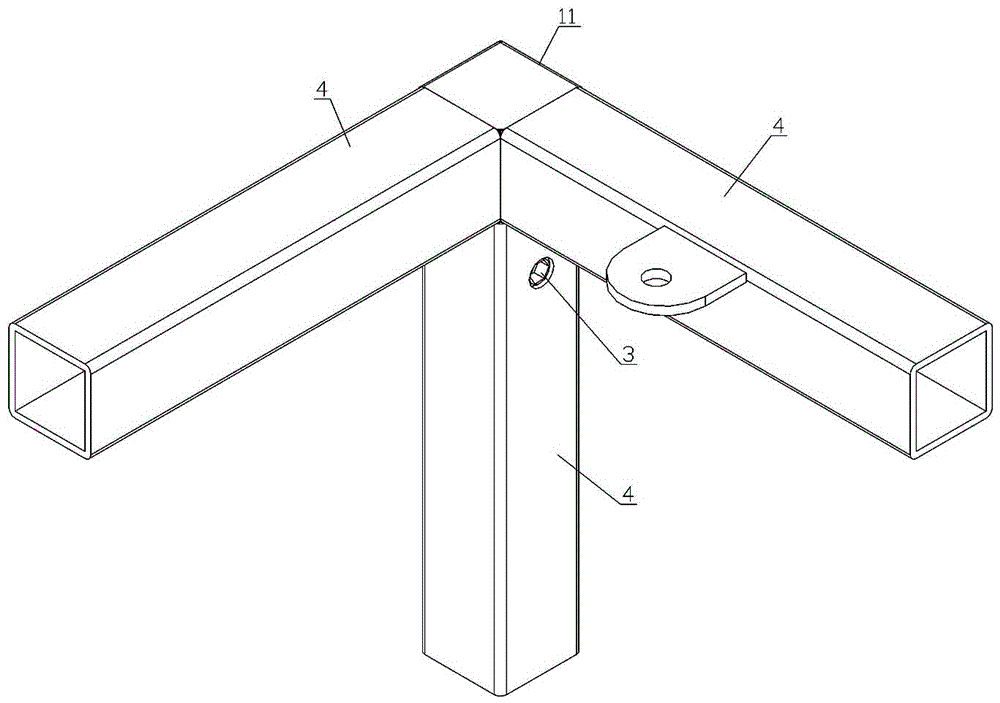

[0030] refer to figure 1 and Image 6 , a hidden connection structure of assembled furniture rods, which includes furniture rods 4 and connecting parts.

[0031] The furniture bar 4 is a long tubular structure with an open end, and the side wall near the end of the furniture bar 4 has a bar through hole 40 .

[0032] The connecting piece adopts a three-way connection structure, which is installed on the furniture bar 4 and includes a connecting insert 1 , a gasket 2 and a connecting shaft 3 .

[0033] specific reference figure 1 , the connecting plug 1 has an end block portion 11 and an insertion rod portion 12, the end block portion 11 is a square block structure with six end block portion side walls 110, and the middle part of the end block portion 11 has a cavity 10, The three end block side walls 110 are connected with inserting rods 12, a total of three inserting rods 12 form the three connection directions of the connector in this embodiment, the cross section of the ...

Embodiment 2

[0039] refer to Figure 7 , The concealed connection structure of assembled furniture rods in this embodiment includes furniture rods 4 and connecting parts, and the connecting parts include connecting inserts 1 , gaskets 2 and connecting shafts 3 . The difference between the connector of this embodiment and Embodiment 1 is that the connector of this embodiment adopts a two-way connection structure, and the two opposite end block side walls 110 of the connecting insert 1 of the connector are connected with inserting rod parts 12. The two inserting rod parts 12 form two connecting directions of the connecting piece in this embodiment on the same straight line, and are used to connect two furniture rods in a straight line. The installation steps of the connection structure in this embodiment are the same as those in Embodiment 1.

Embodiment 3

[0041] refer to Figure 8 , The concealed connection structure of assembled furniture rods in this embodiment includes furniture rods 4 and connecting parts, and the connecting parts include connecting inserts 1 , gaskets 2 and connecting shafts 3 . The difference between the connector of this embodiment and Embodiment 1 is that the connector of this embodiment adopts a two-way connection structure, and the two adjacent end block side walls 110 of the connecting insert 1 of the connector are connected with inserting rods 12 , A total of two inserting rod parts 12 form two connecting directions perpendicular to each other of the connecting member in this embodiment, and are used to vertically connect two furniture rods. The installation steps of the connection structure in this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com