Explosion-proof electric horn

An electric horn and explosion-proof technology, which is applied in the direction of sound-generating devices and instruments, can solve the problems of single applicable place, small sound generation, high power consumption, etc., and achieve the effects of easy manufacturing and implementation, sounding of the horn, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings of the description.

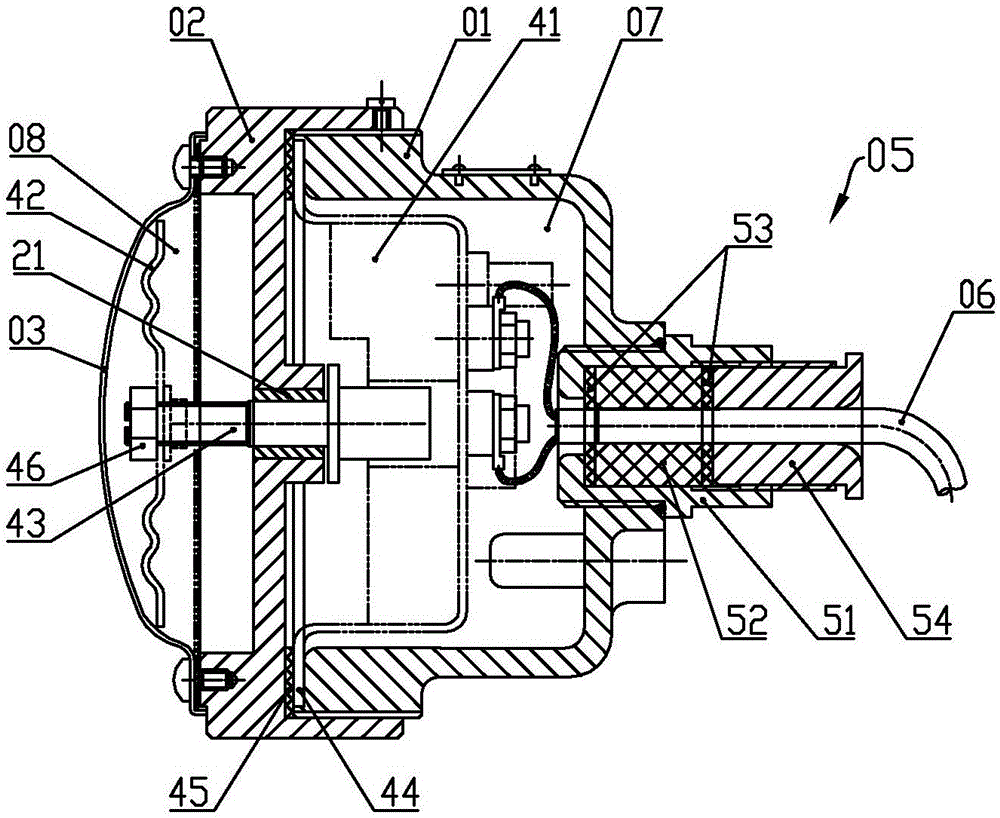

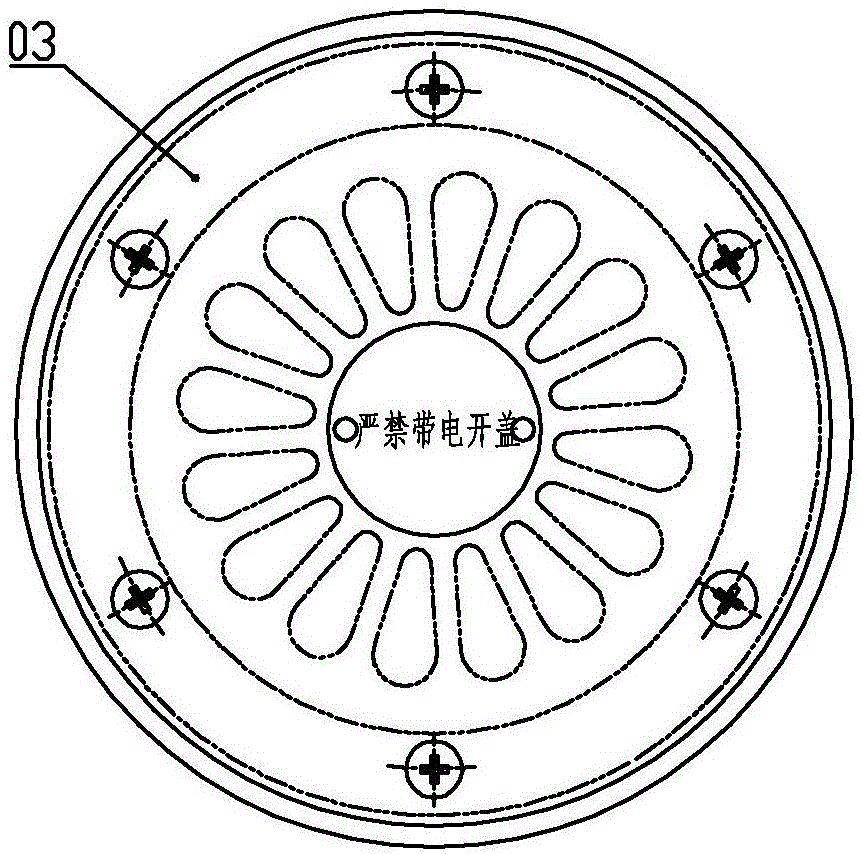

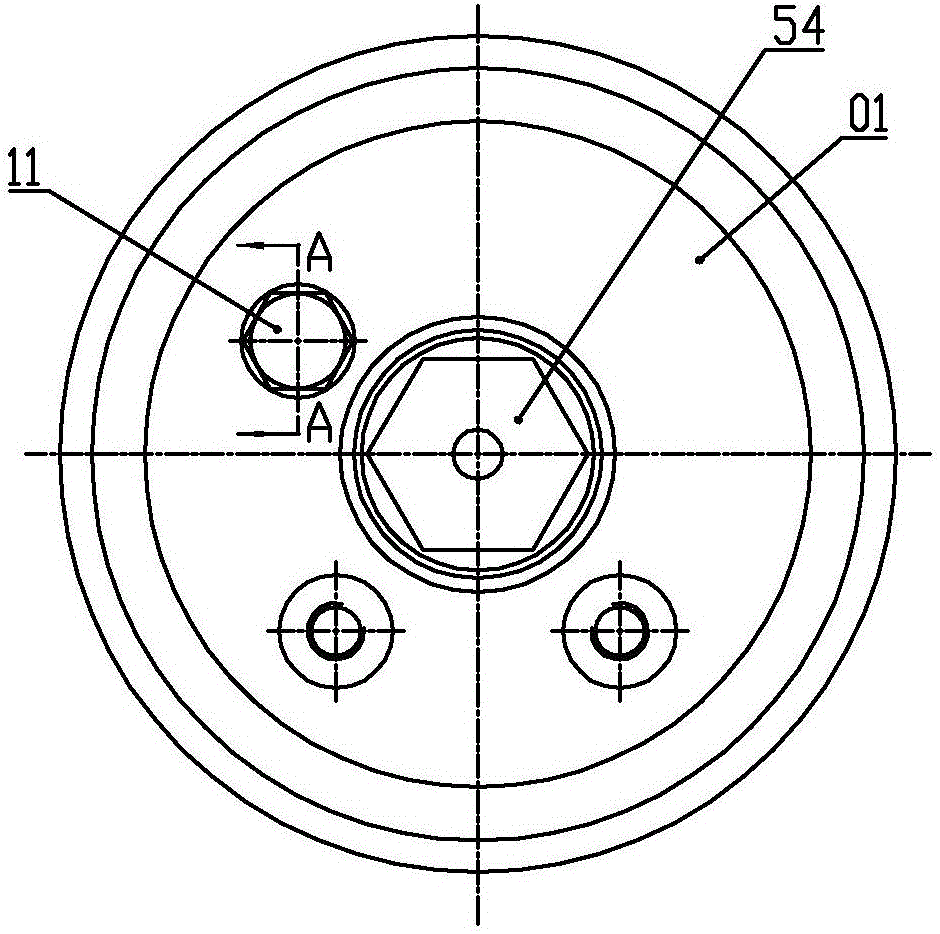

[0032] Such as Figure 1-4 As shown, the explosion-proof electric horn includes a housing 01, a cover 02, a cover 03, an electric horn main body 41, a sounding diaphragm 42, an explosion-proof cable lead-in device 05, and a cable 06. The housing 01, the cover 02, and the cover 03 are assembled on Together, a first accommodating chamber 07 is formed between the housing 01 and the cover 02, a second accommodating chamber 08 is formed between the cover 02 and the cover 03, the electric horn main body 41 is assembled in the first accommodating chamber 07, and the sounding diaphragm 42 is located In the second accommodation chamber 08, the axially movable iron core shaft 43 passes through the cover 02 and its two ends are respectively connected to the electric horn main body 41 and the sounding diaphragm 42. The explosion-proof cable lead-in device 05 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thread length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com