A preparation method of high specific capacitance flexible supercapacitor anode material

A technology for supercapacitors and anode materials, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve problems such as safety and cycle stability restricting applications, and achieve accelerated charge transfer rate, excellent conductivity, and production high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

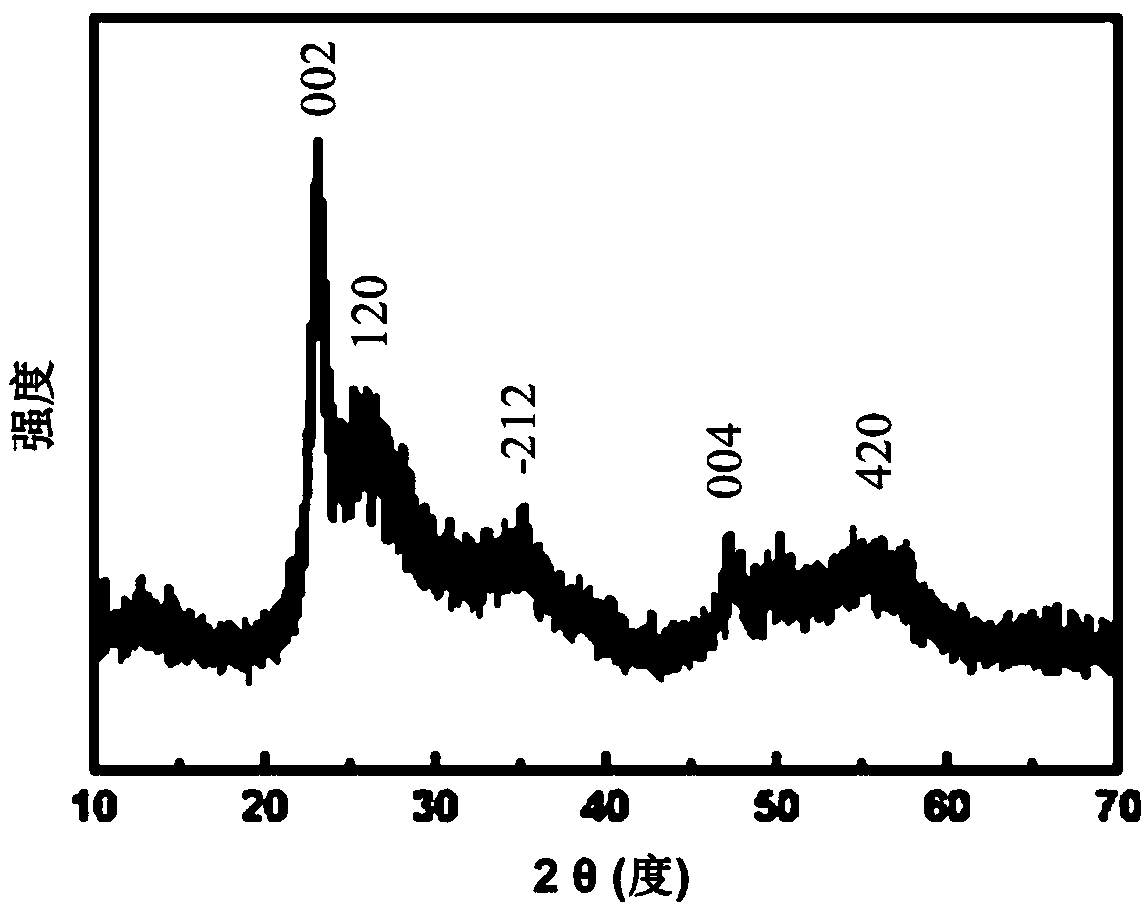

[0030] Dissolve 5g tungstic acid and 1.42g molybdenum oxide in 60ml H 2 o 2 middle. Add an equal amount of deionized water and ethylene glycol to dilute the solution to 200ml to obtain the desired hydrothermal reaction precursor solution. Mix 20ml of the above precursor solution with the same amount of deionized water, pour it into the liner of a polytetrafluoroethylene hydrothermal kettle, and keep it warm at 120°C for 5 hours. Subsequently, the desired molybdenum-doped tungsten oxide nanoparticle powder is obtained through centrifugation, washing and drying.

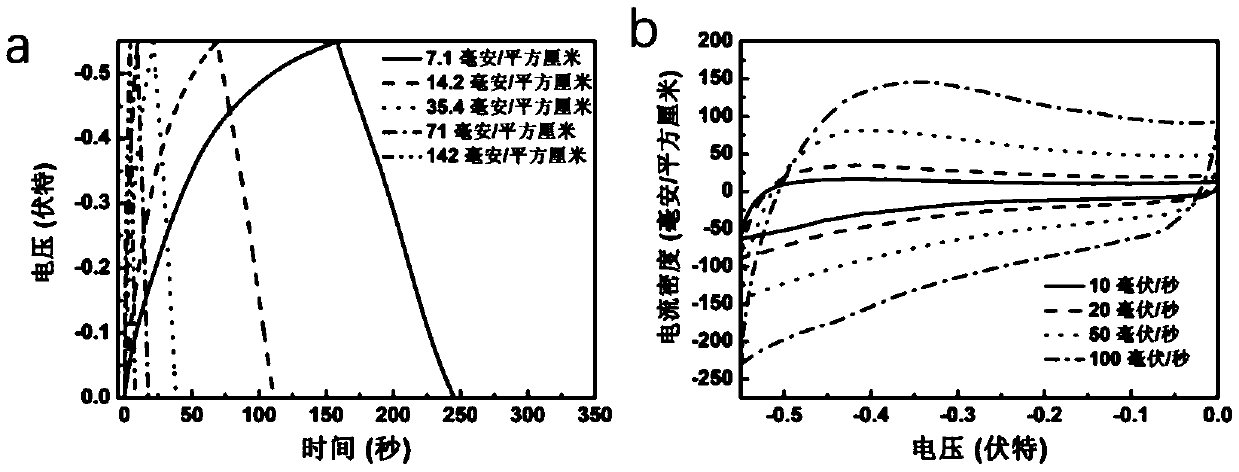

[0031] Mix 100 mg of the above-mentioned molybdenum-doped tungsten oxide powder with 10 mg of CNTs and 40 mg of sodium dodecylbenzenesulfonate in 30 ml of deionized water, and disperse by ultrasonic for 90 minutes to obtain a uniform dispersion. Pour the above dispersion into a sand core funnel for suction filtration. After pumping until there is no free water, add deionized water to wash 3 times, and clean the sodi...

Embodiment 2

[0034] Dissolve 5g tungstic acid and 0.71g molybdenum oxide in 60ml H 2 o 2 middle. Add an equal amount of deionized water and ethylene glycol to dilute the solution to 200ml to obtain the desired hydrothermal reaction precursor solution. Mix 20ml of the above precursor solution with the same amount of deionized water, pour it into the liner of a polytetrafluoroethylene hydrothermal kettle, and keep it warm at 120°C for 5 hours. Subsequently, the desired molybdenum-doped tungsten oxide nanoparticle powder is obtained through centrifugation, washing and drying.

[0035] Mix 100 mg of the above-mentioned molybdenum-doped tungsten oxide powder with 10 mg of CNTs and 40 mg of sodium dodecylbenzenesulfonate in 30 ml of deionized water, and disperse by ultrasonic for 90 minutes to obtain a uniform dispersion. Pour the above dispersion into a sand core funnel for suction filtration. After pumping until there is no free water, add deionized water to wash 3 times, and clean the sodi...

Embodiment 3

[0038] Dissolve 5g tungstic acid and 2.84g molybdenum oxide in 60ml H 2 o2 middle. Add an equal amount of deionized water and ethylene glycol to dilute the solution to 200ml to obtain the desired hydrothermal reaction precursor solution. Mix 20ml of the above precursor solution with the same amount of deionized water, pour it into the liner of a polytetrafluoroethylene hydrothermal kettle, and keep it warm at 120°C for 5 hours. Subsequently, the desired molybdenum-doped tungsten oxide nanoparticle powder is obtained through centrifugation, washing and drying.

[0039] Mix 100 mg of the above-mentioned molybdenum-doped tungsten oxide powder with 10 mg of CNTs and 40 mg of sodium dodecylbenzenesulfonate in 30 ml of deionized water, and disperse by ultrasonic for 90 minutes to obtain a uniform dispersion. Pour the above dispersion into a sand core funnel for suction filtration. After pumping until there is no free water, add deionized water to wash 3 times, and clean the sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com