Crop pretreatment apparatus having liquid fluidity

A pretreatment device and fluidity technology, applied in food science, food forming, application, etc., can solve the problems of insufficient contact between crops and soaking liquid, affecting the treatment effect, and inconvenient operation, so as to improve work reliability and operation Convenience, the effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

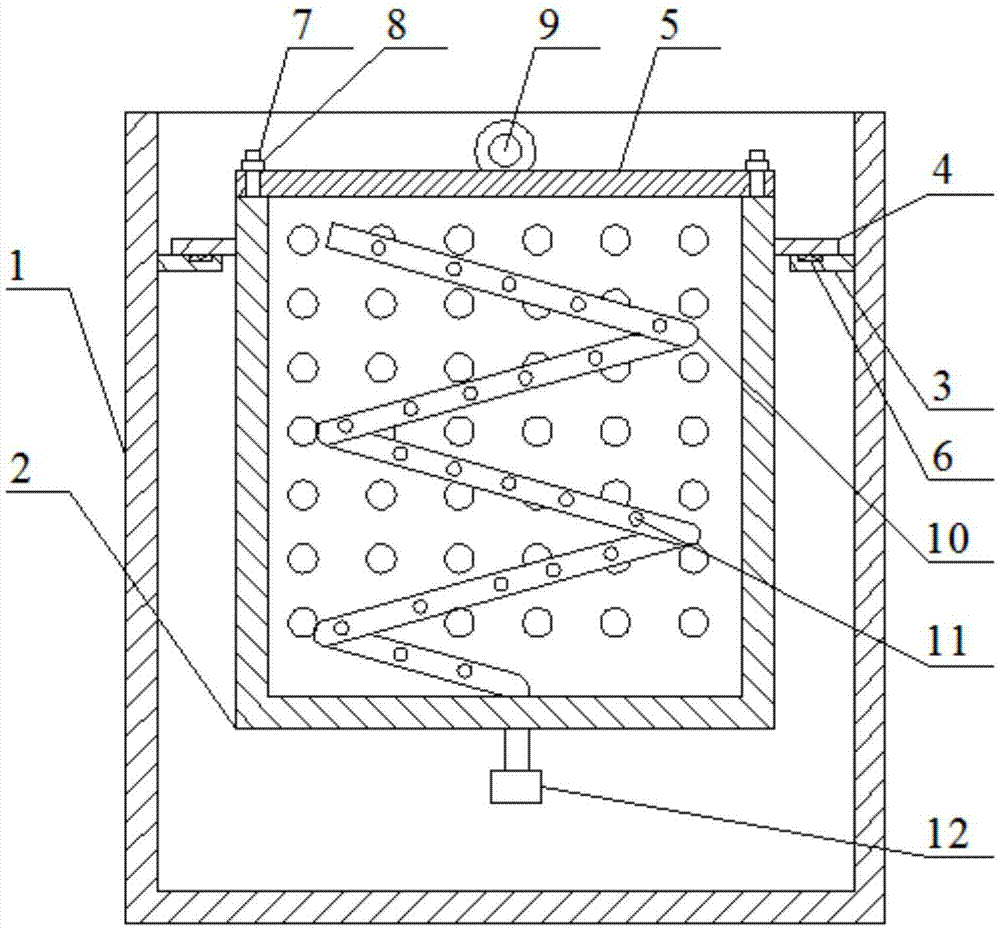

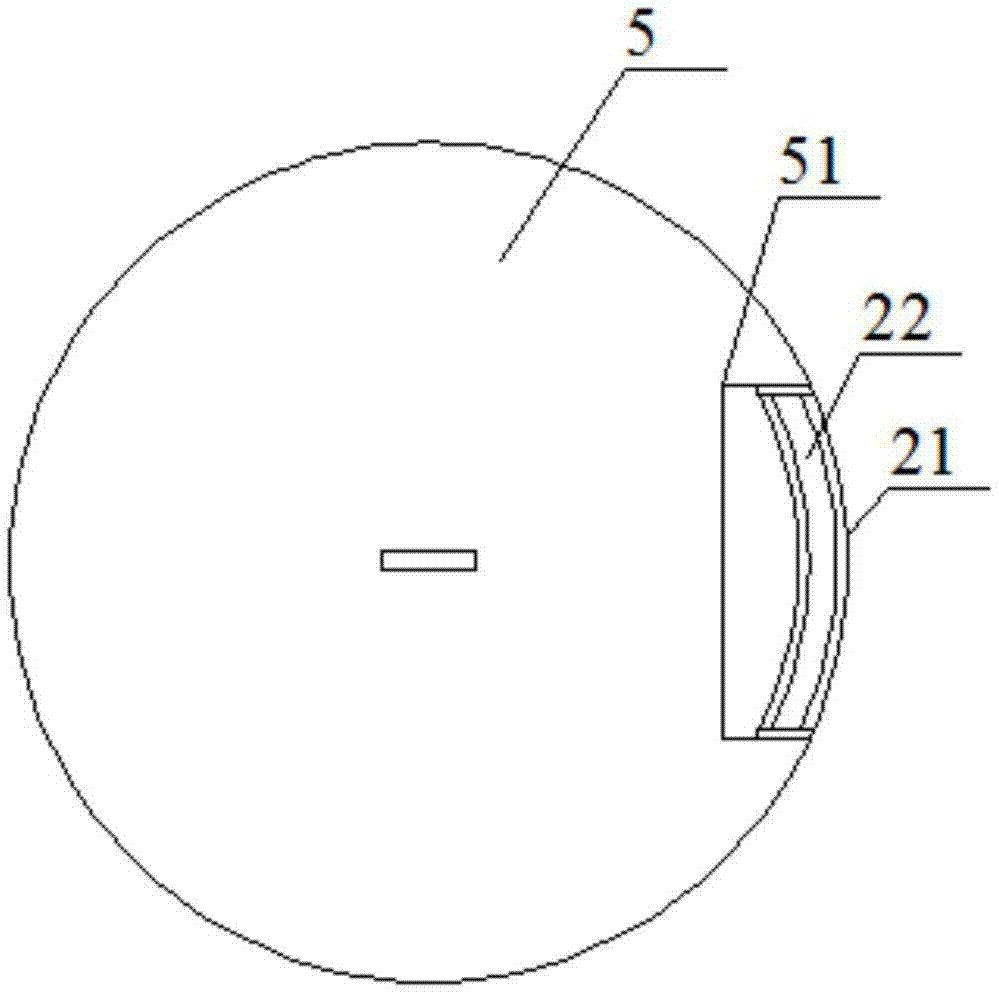

[0030] like figure 1 and figure 2 As shown, the crop pretreatment device with liquid fluidity includes an outer barrel 1, an inner barrel 2, an outer fixing ring 3, an inner fixing ring 4, and an inner barrel cover 5; the outer fixing ring 3 is fixed on the inner surface of the outer barrel 1, and the inner fixing ring The ring 4 is fixed on the outer surface of the inner barrel 2, the inner barrel 2 is arranged in the outer barrel 1, and the inner barrel 2 is suspended on the outer fixing ring 3 through the inner fixing ring 4; the inner barrel cover 5 is arranged on the top of the inner barrel 2; the inner barrel 2 is composed of a perforated plate; It also includes a spiral tube 10 arranged in the inner barrel 2. A plurality of liquid outlet holes 11 are evenly opened on the spiral tube 10. The central axis of the spiral tube 10 coincides with the axis of the inner barrel 2. The lower end of the spiral tube 10 extends to the outside of the bottom of the inner barrel 2. It...

Embodiment 2

[0036] like figure 1 As shown, on the basis of Embodiment 1, this embodiment further includes a sealing ring 6 disposed on the upper surface of the outer fixing ring 3 , and the sealing ring 6 is in contact with the lower surface of the inner fixing ring 4 .

[0037] A sealing ring 6 is provided to prevent soaking liquid from overflowing from between the outer fixing ring 3 and the inner fixing ring 4 .

Embodiment 3

[0039] like figure 1 As shown, on the basis of Embodiment 1, the present embodiment also includes a plurality of screw rods 7 arranged vertically on the top of the inner barrel 2, and the screw rods 7 run through the inner barrel cover 5; The inner barrel cover 5 is pressed on the top of the inner barrel 2.

[0040] The inner barrel cover 5 is pressed tightly on the top of the inner barrel 2 to avoid the flow of the soaking liquid and the inner barrel cover 5 is pushed away, thereby improving the working reliability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com