Staggered and stacked transfer box

A turnover box and stacking technology, which is applied in the field of dislocation stacking turnover boxes, can solve the problems of easy crushing, poor load-bearing capacity and poor pressure-bearing capacity of the turnover box, and achieves strong anti-dumping ability, improved folding efficiency, The effect of improving performance and support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

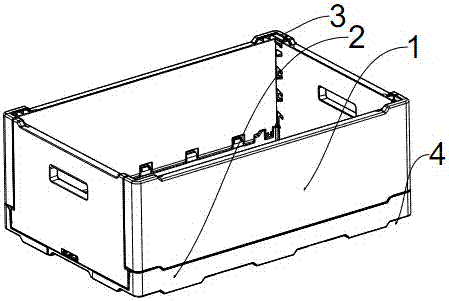

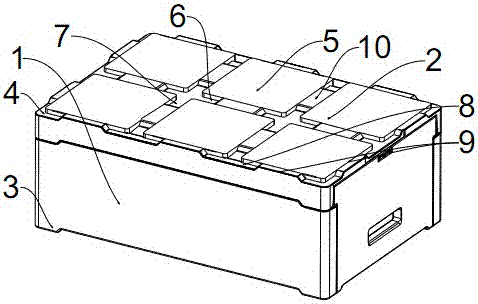

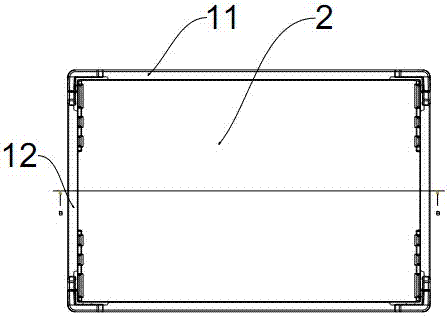

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the turnover box described in this embodiment includes a base plate 2 and four side plates 1, the base plate 2 and the four side plates 1 form a semi-closed box, and the four sides at the upper end of the box The side plate 1 corresponding to the four corners is provided with an upward raised block 3, and the bottom plate 2 corresponding to the four corners of the lower end of the box is provided with an inner concave cavity 4 whose shape and size are consistent with the raised block 3. The cavity 4 and the protruding block 3 can be positioned in cooperation. The protruding block 3 is an L-shaped structure, and the corners of the protruding block 3 correspond to the corners of the upper end of the box body.

[0038] Six positioning protrusions 5 are arranged on the lower surface of the base plate 2, and a No. 1 groove 6 is formed between the positioning protrusions 5 in the length direction of the base p...

Embodiment 2

[0041] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the turnover box described in this embodiment includes a base plate 2 and four side plates 1, the base plate 2 and the four side plates 1 form a semi-closed box, and the four sides at the upper end of the box The side plate 1 corresponding to the four corners is provided with an upward raised block 3, and the bottom plate 2 corresponding to the four corners of the lower end of the box is provided with an inner concave cavity 4 whose shape and size are consistent with the raised block 3. The cavity 4 and the protruding block 3 can be positioned in cooperation. The protruding block 3 is an L-shaped structure, and the corners of the protruding block 3 correspond to the corners of the upper end of the box body.

[0042] Six positioning protrusions 5 are arranged on the lower surface of the base plate 2, and a No. 1 groove 6 is formed between the positioning protrusions 5 in the length direction of the base p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com