A steam ironing method for improving flatness of ironing

A flatness and ironing technology, applied in the field of clothing, can solve the problems of unsuitable ironing, long ironing time, poor ironing effect, etc., and achieve the effect of improving flatness and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

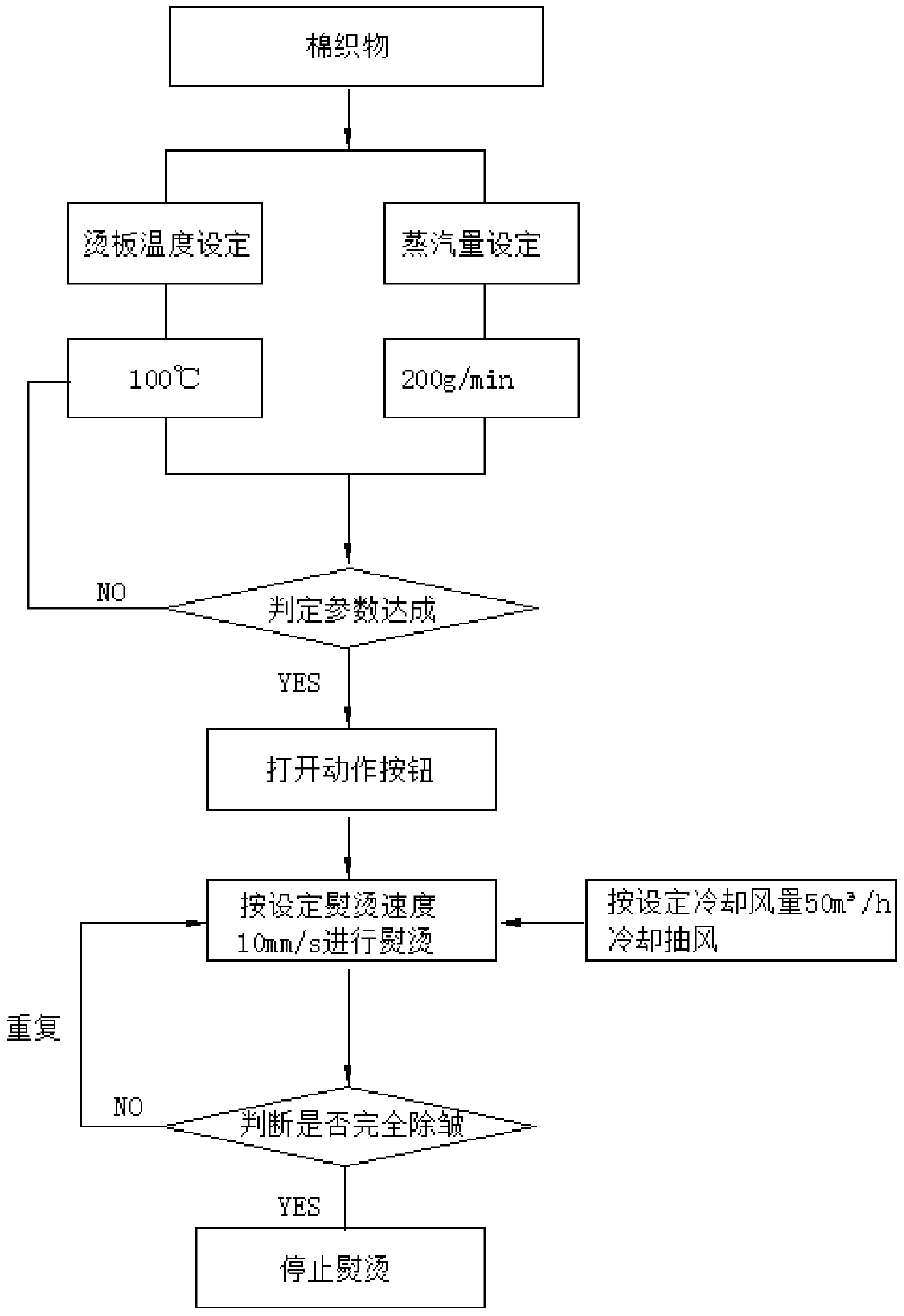

[0034] like figure 1 As shown, the steam ironing method of a hanging ironing machine with automatic ironing function provided in this embodiment to improve ironing flatness, wherein the fabric to be ironed is cotton fabric, comprising the following steps:

[0035] S1. Set a temperature parameter for the garment steamer to control the heating device inside the ironing board to heat the ironing board; wherein, the temperature parameter is 90-110° C., and the heating device is a thermocouple, a heat pipe or a PTC heater. In this embodiment, the preferred temperature parameter is 100°C, which can make the cotton fabric reach a good ironing temperature and ensure the ironing effect;

[0036] At the same time, set the steam volume parameters for the garment ironing machine, control the steam generator to generate steam and spray it from the steam outlet of the ironing board; the steam volume parameter is 180-220g / min, and the steam generation method is the The water inside is heate...

Embodiment 2

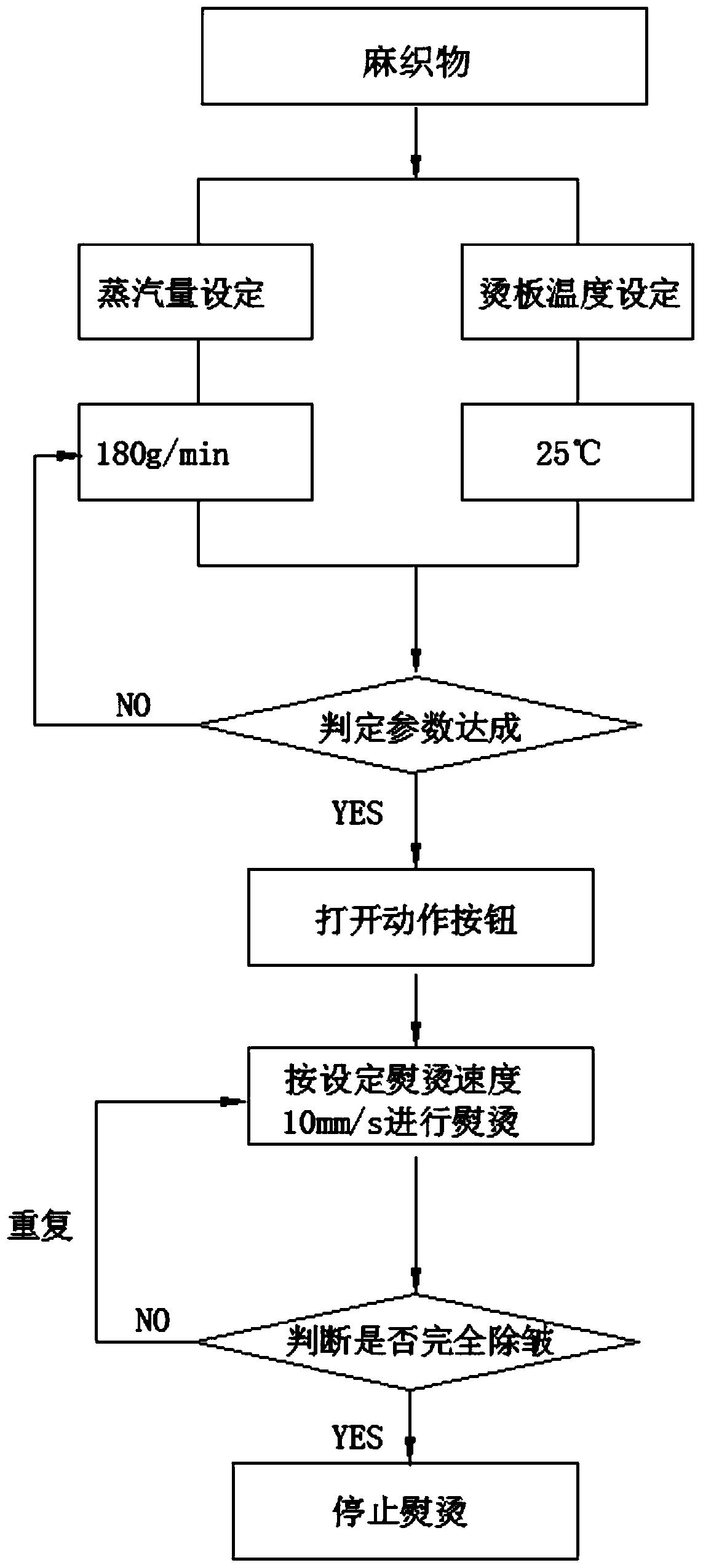

[0043] like figure 2 As shown, the present embodiment provides a steam ironing method for improving ironing flatness, wherein the fabric to be ironed is hemp fabric, comprising the following steps:

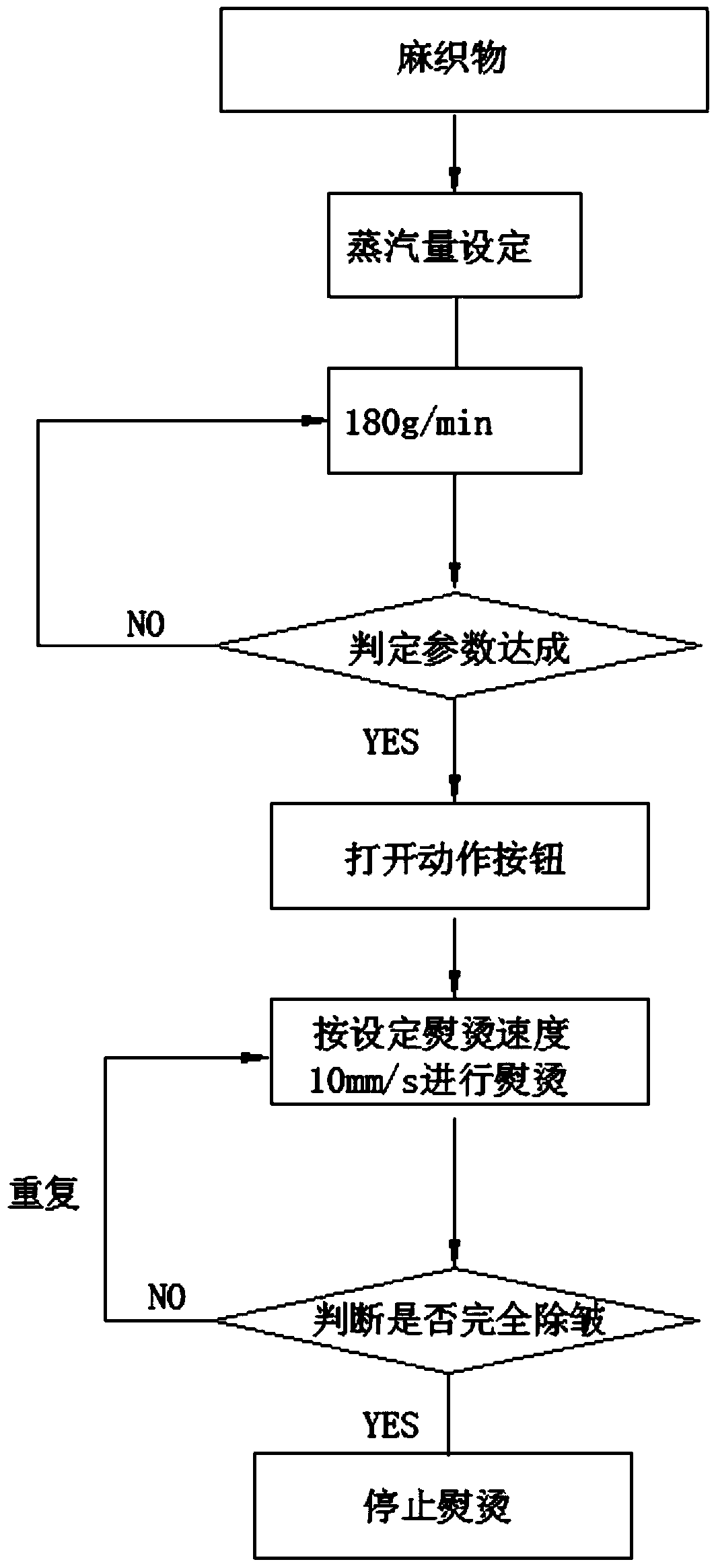

[0044] S1. Set a temperature parameter for the garment steamer to control the heating device inside the ironing board to heat the ironing board; wherein, the temperature parameter is 20-30° C., and the heating device is a thermocouple, a heating pipe or a PTC heater. In this embodiment, the preferred temperature parameter is 25°C, making it the same as the ambient temperature. When the linen fabric is ironed, its temperature can be the ambient temperature. Therefore, when ironing the linen fabric, the temperature parameter can not be adjusted. setting, that is, if image 3 The mode of the shown embodiment three;

[0045] At the same time, set the steam volume parameters for the garment steamer, control the steam generator to generate steam and spray it from the steam outlet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com