Turbomachine comprising a vertical shaft

一种涡轮机组、涡轮机的技术,应用在涡轮/推进装置的润滑、机械设备、发动机制造等方向,能够解决降低效力、增加涡轮机组重量、增加重量等问题,达到提高效率、节省重量、空间节省的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

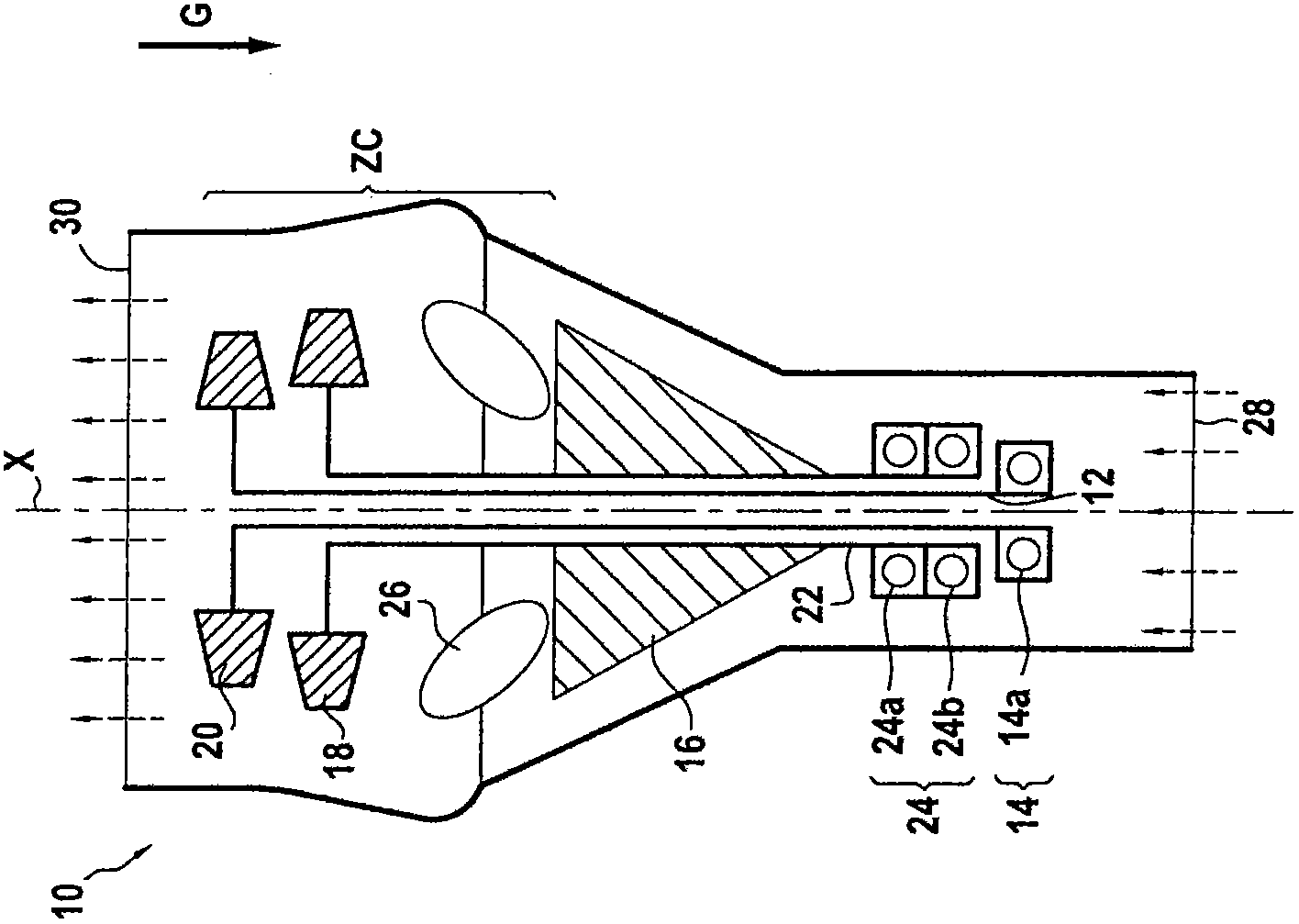

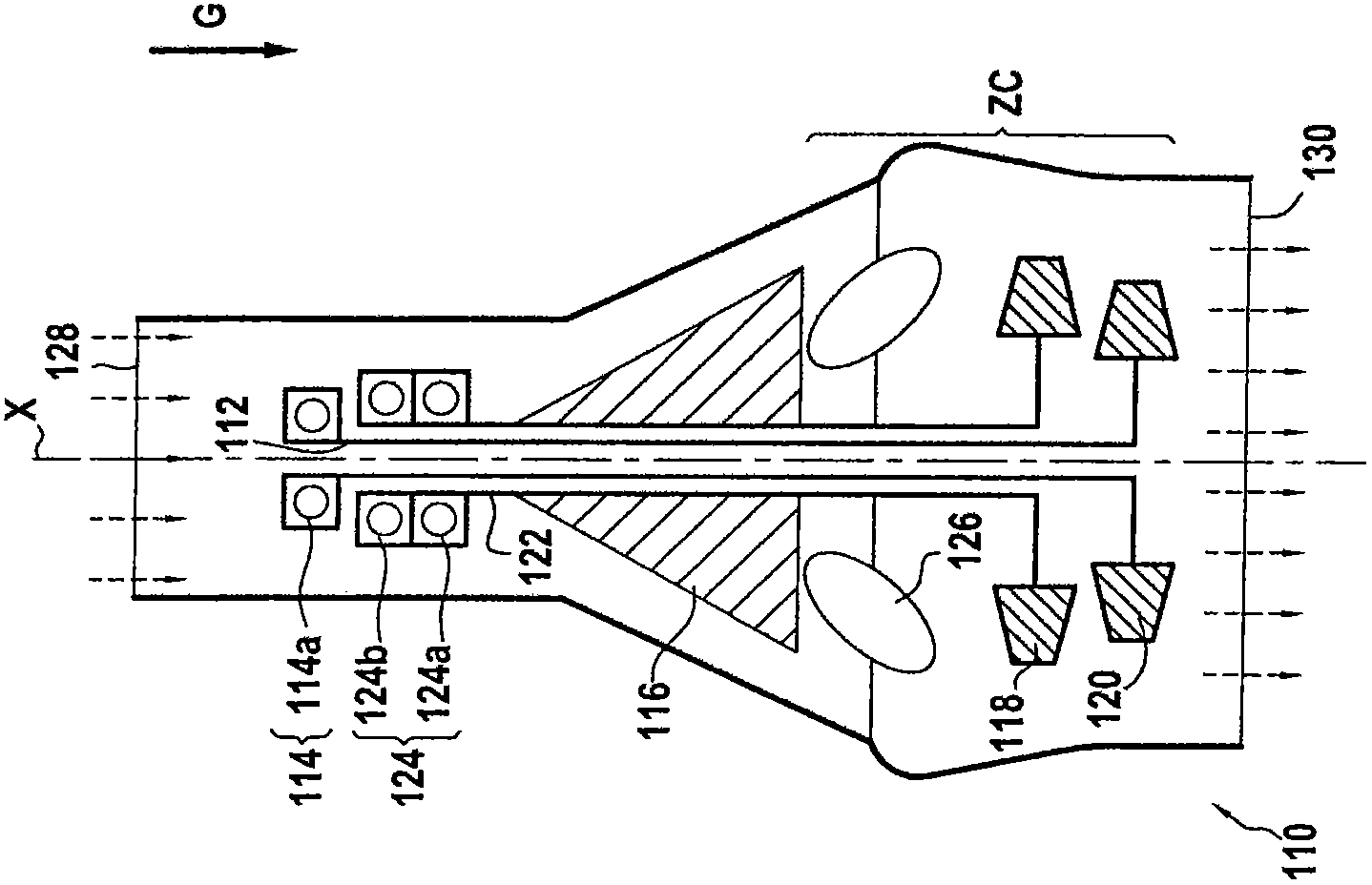

[0036] FIG. 1 shows a first exemplary embodiment of a turbomachine 10 in a schematic longitudinal section on the axis X of the turbomachine 10 . The axis X of the turbomachine 10 adopts a vertical orientation, ie parallel to the direction of gravity G indicated by the thick arrow. The dashed arrows indicate the direction of gas flow through the turbomachine.

[0037] The turbomachine 10 includes a shaft 12 oriented vertically and supported by a single bearing 14, the turbomachine shown in normal use. The turbomachine 10 comprises a compressor 16, an associated turbine 18 and a free turbine 20, the shown shaft 12 forming a first shaft on which is mounted a turbine wheel forming part of the free turbine 20 and a single bearing 14 forming a first single bearing.

[0038] In the illustrated embodiment, the free turbine 20 and the connected turbine 18 each have only a single turbine wheel. Of course, in another way, both the connected turbine and / or the free turbine have multiple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com