A method of workpiece defect detection based on machine vision

A defect detection and machine vision technology, applied in the direction of optical testing flaws/defects, instruments, measuring devices, etc., can solve problems such as high cost, inconspicuousness, and more glue, achieve high accuracy, improve accuracy, and ensure accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

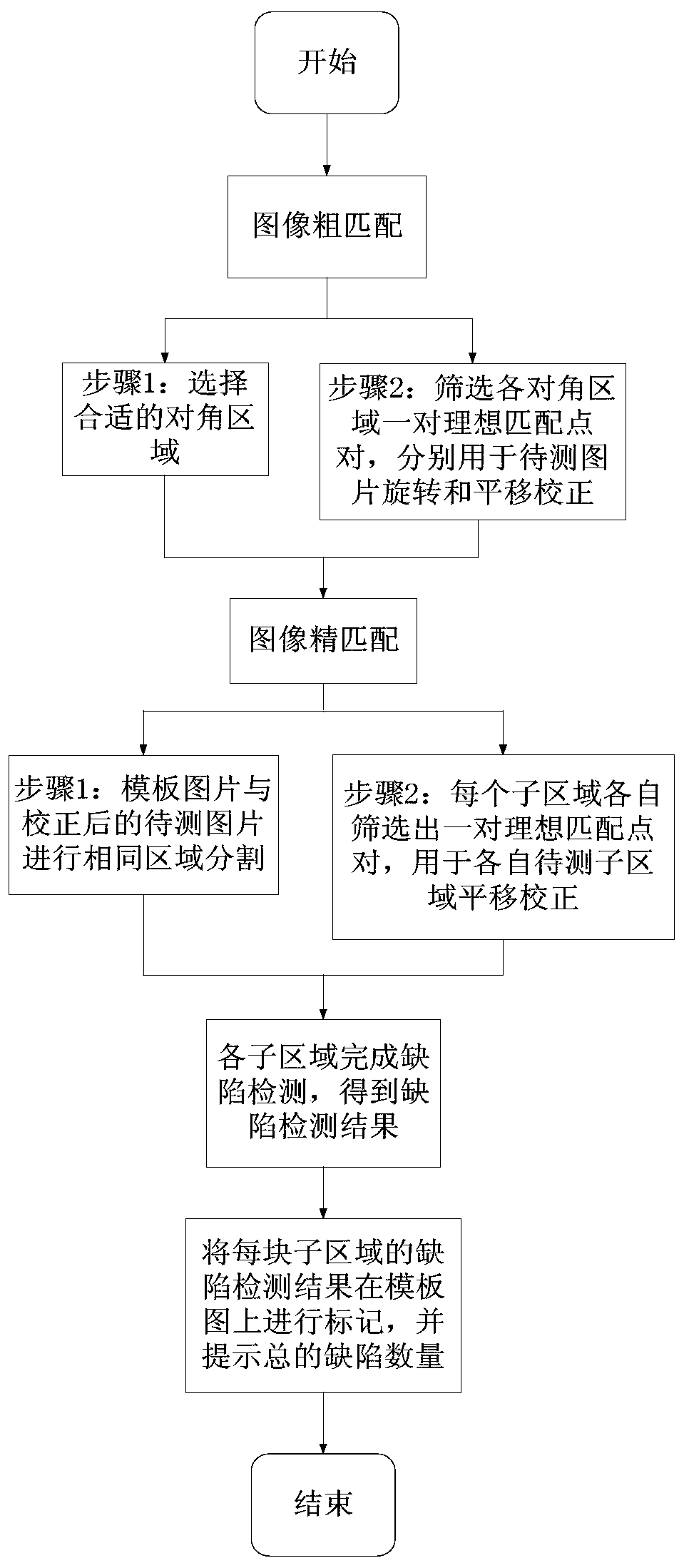

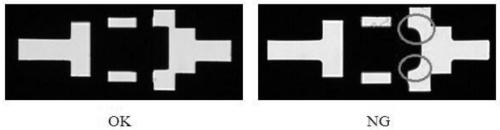

[0041] The present invention will be further described below in conjunction with the drawings and specific embodiments:

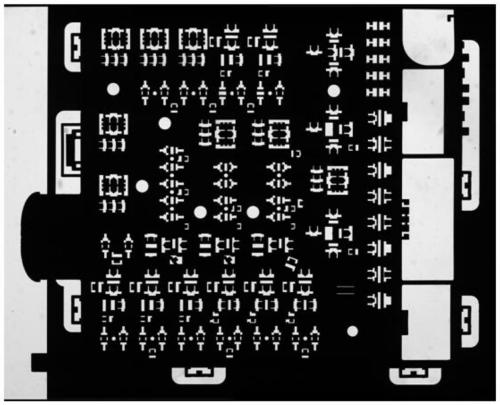

[0042] The machine vision inspection system used in the present invention includes an industrial camera, an industrial lens, and a light source, and the acquired picture is placed in a computer for defect detection. In this embodiment, a GS3-U3-120S6M-C area scan camera, a DTCM110-240 industrial telecentric lens and a light source matched with the lens are used. The lens satisfies the high-precision imaging of the workpiece. When the camera meets the actual accuracy requirements, the imaging target surface of the camera cannot accommodate the entire workpiece. The use of multi-station shooting is solved. The light source is selected as the DC110-240 matched with the lens. The overall hardware combination meets the requirements of industrial detection accuracy.

[0043] The process of the workpiece defect detection method provided by the present invention is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com