A method of pipe butt welding

A welding method and pipeline technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as hidden dangers in the use of pipelines, improve the safety of use, increase the margin of misalignment, and avoid the reduction of pipeline wall thickness. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

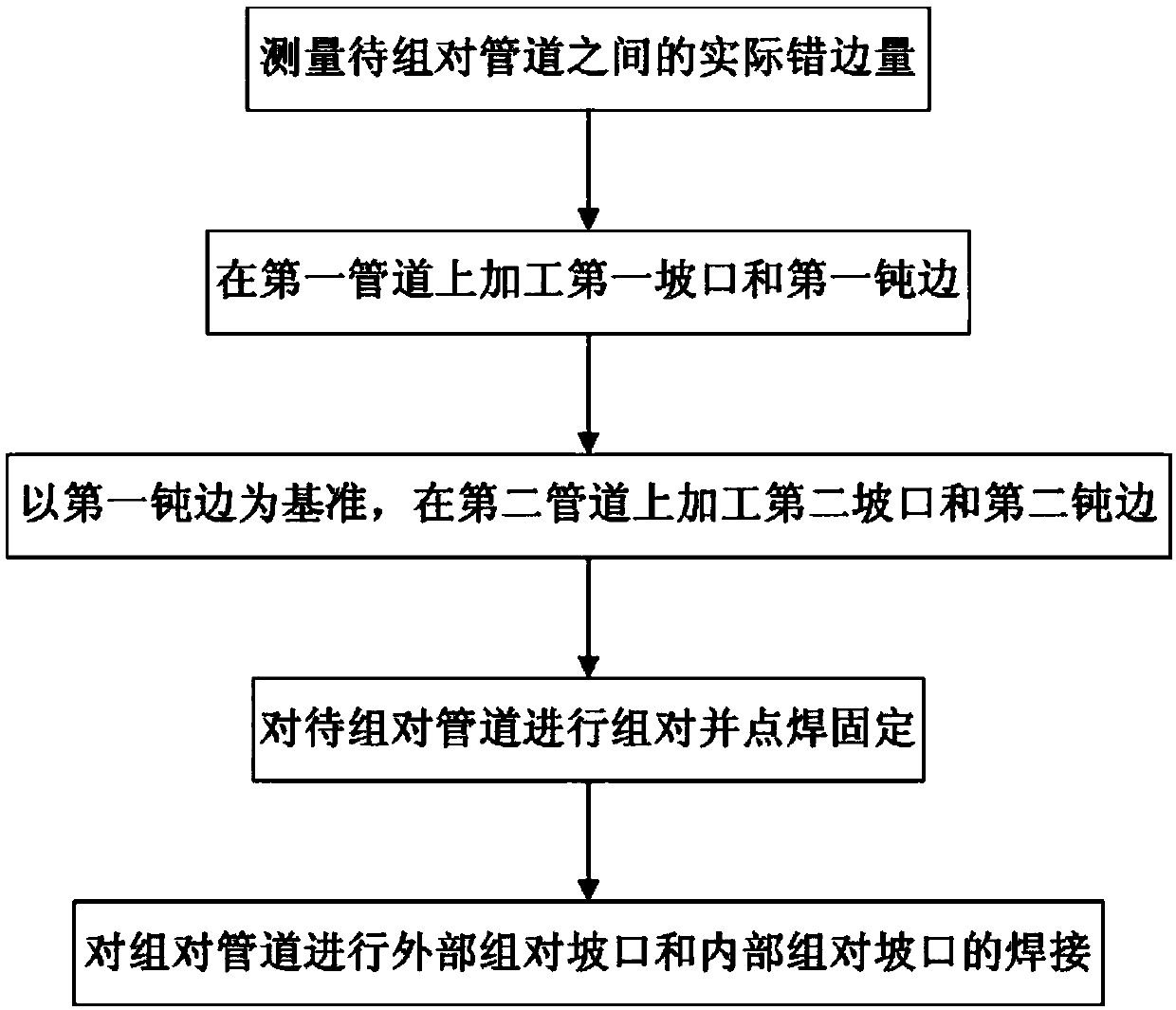

[0032] The technical solutions in the present invention will be described in detail below in conjunction with the accompanying drawings.

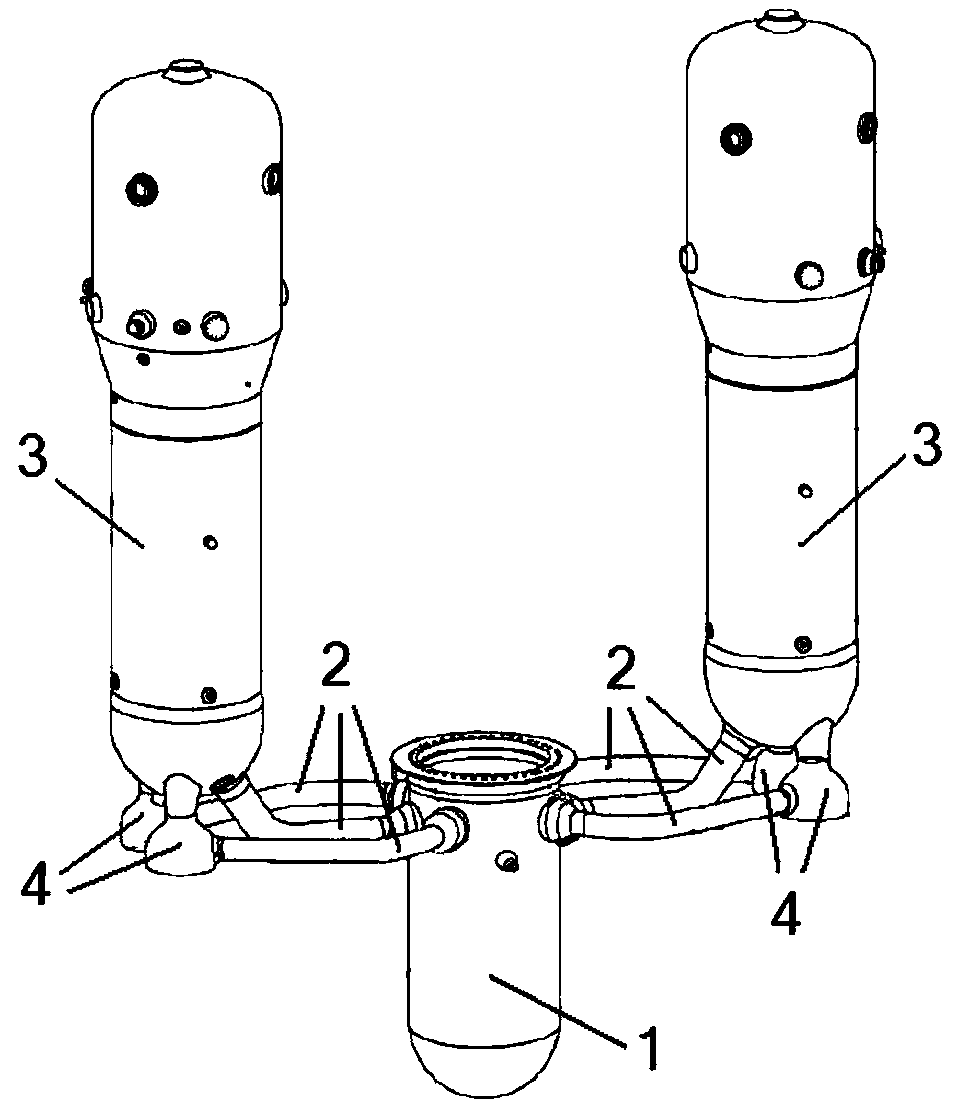

[0033] to combine figure 2 and image 3As shown, adopt the pipe group butt welding method of the present invention, the specific steps of grouping and welding the pipelines with misalignment amount are as follows:

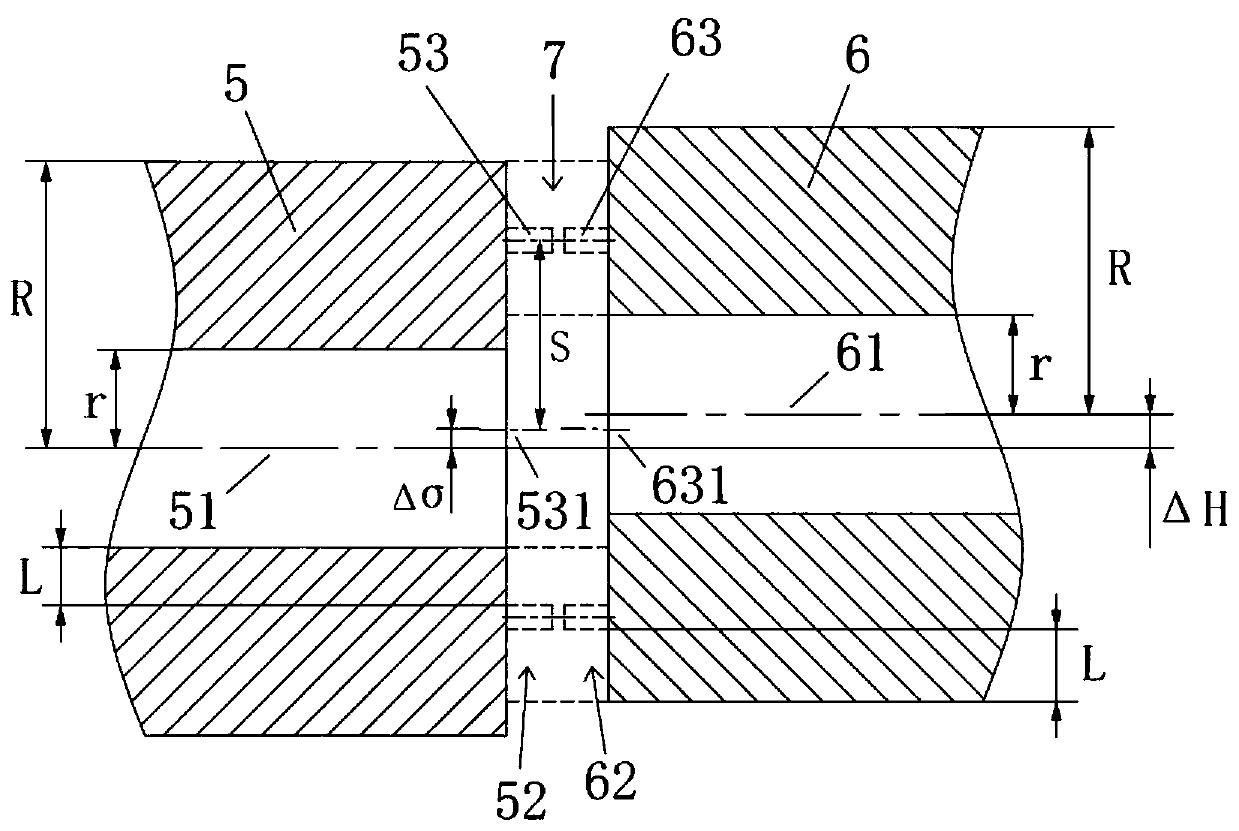

[0034] Step 1: Measure the actual misalignment between the pair of pipes. The pair of pipes includes a first pipe 5 and a second pipe 6, wherein the first pipe 5 and the second pipe 6 have an inner diameter r and an outer diameter R. Using laser measurement technology, respectively measure the spatial position of the axis 51 of the first pipe 5 at the paired port and the axis 61 of the second pipe 6 at the paired port, and determine the actual misalignment amount ΔH and misalignment between the two direction. Wherein, when 0≤ΔH<(R-r), that is, when the actual misalignment between the paired pipes is less than the wall thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com