Clamp for mounting magnet

A technology for mounting magnets and fixtures, applied in the field of magnet mounting fixtures, can solve the problems of time-consuming and laborious installation, inability to meet production needs, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

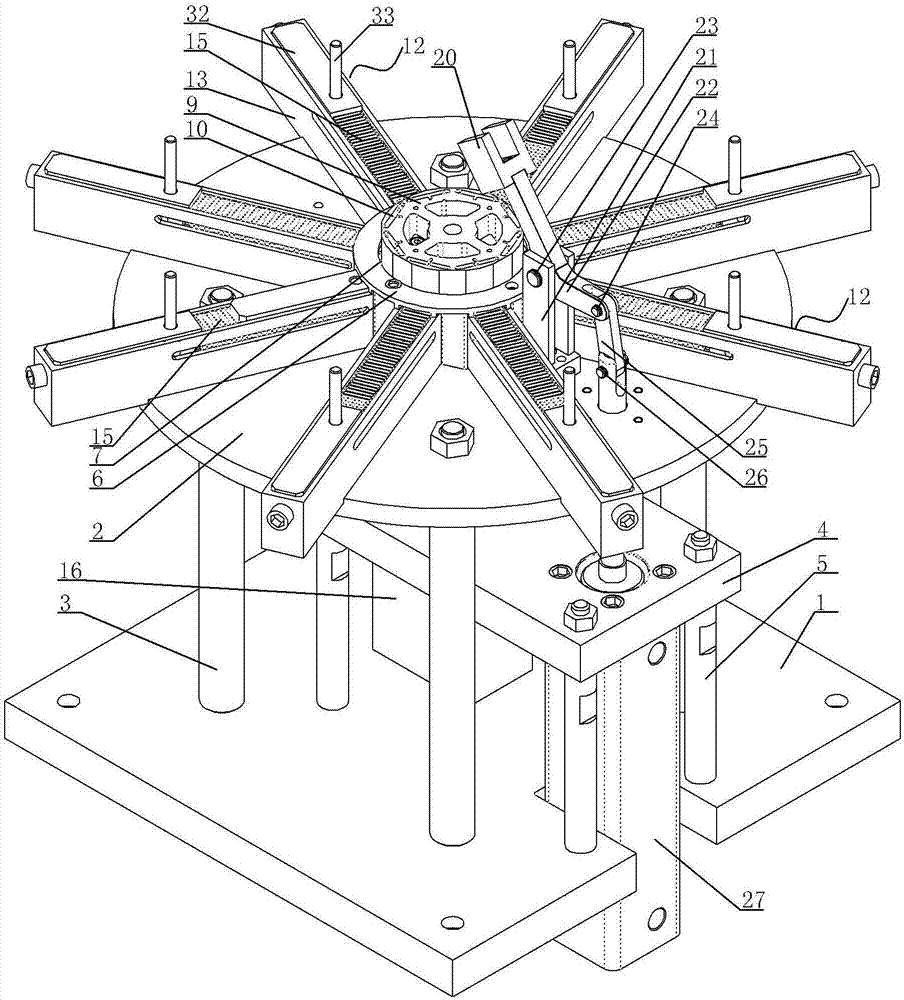

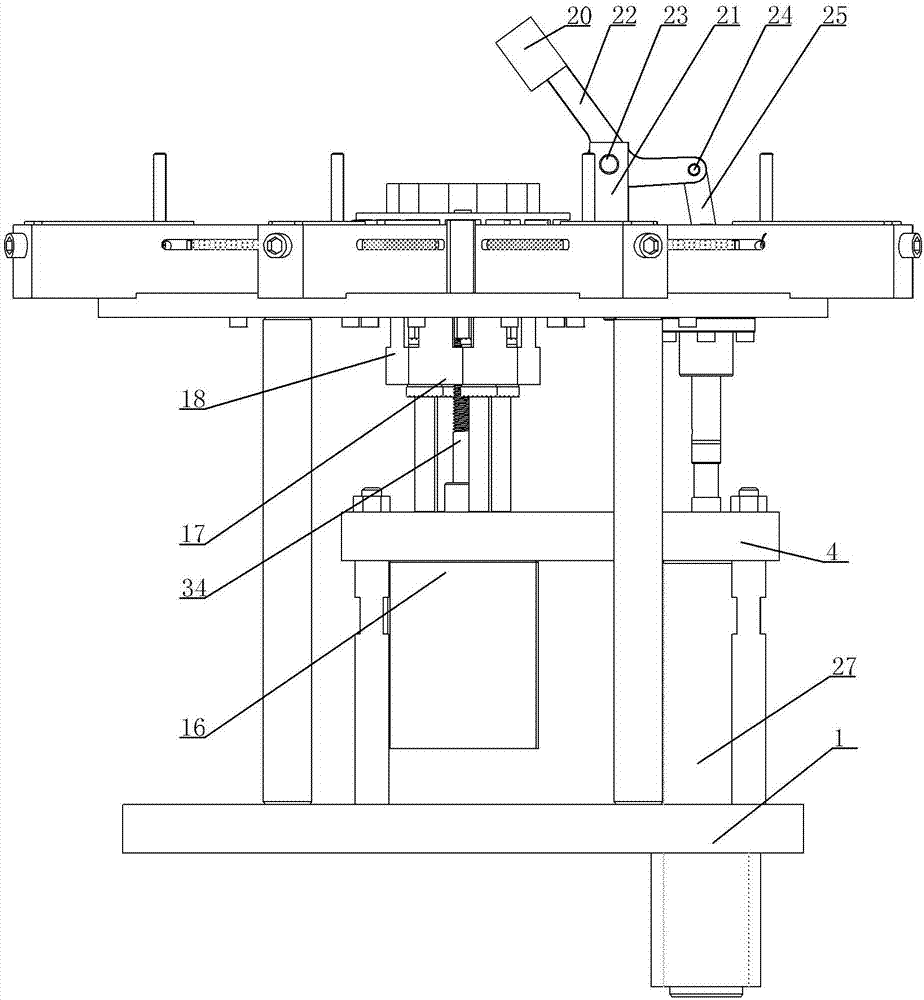

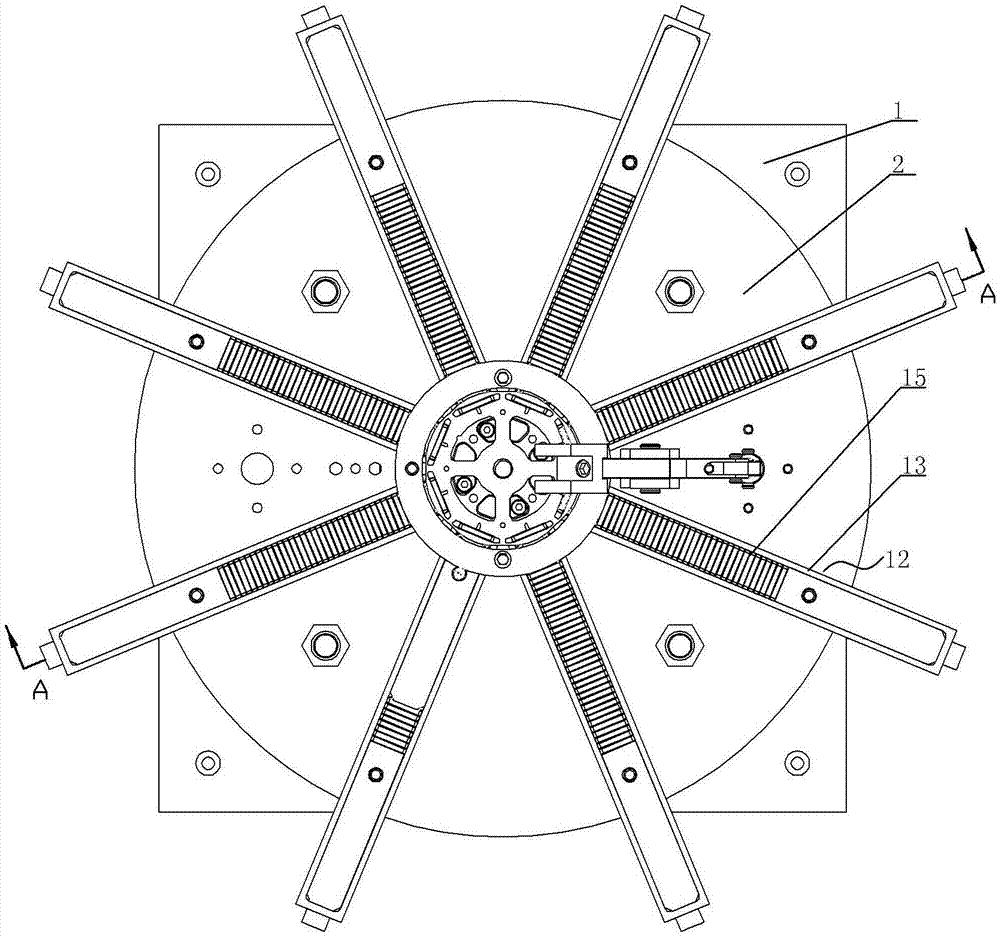

[0018] A kind of magnetic fixture, see Figure 1 ~ Figure 4 : It includes a base plate 1, an upper plate 2 is arranged directly above the base plate 1, the upper plate is supported on the base plate 1 through a plurality of first columns 3, and is arranged parallel to the base plate 2, and an installation is arranged between the base plate 1 and the upper plate 2. The plate 4 and the mounting plate 4 are supported on the bottom plate 1 through a number of second columns 5, and the center position of the upper plate 2 is provided with an upward convex structure 6, and the outer ring part of the upward convex structure 6 is fastened to the center position of the upper end surface of the bottom plate 1 by screws , the center position of the bottom plate 1 is the center hole, the center of the raised structure 6 is the positioning cavity 7, the rotor positioning fixture 8 is arranged in the installation cavity 7, the bottom of the rotor 9 is positioned on the rotor positioning fixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com