Film surface treatment equipment

A surface treatment and equipment technology, applied in the field of thin film surface treatment equipment, to achieve the effects of low production cost, cost saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

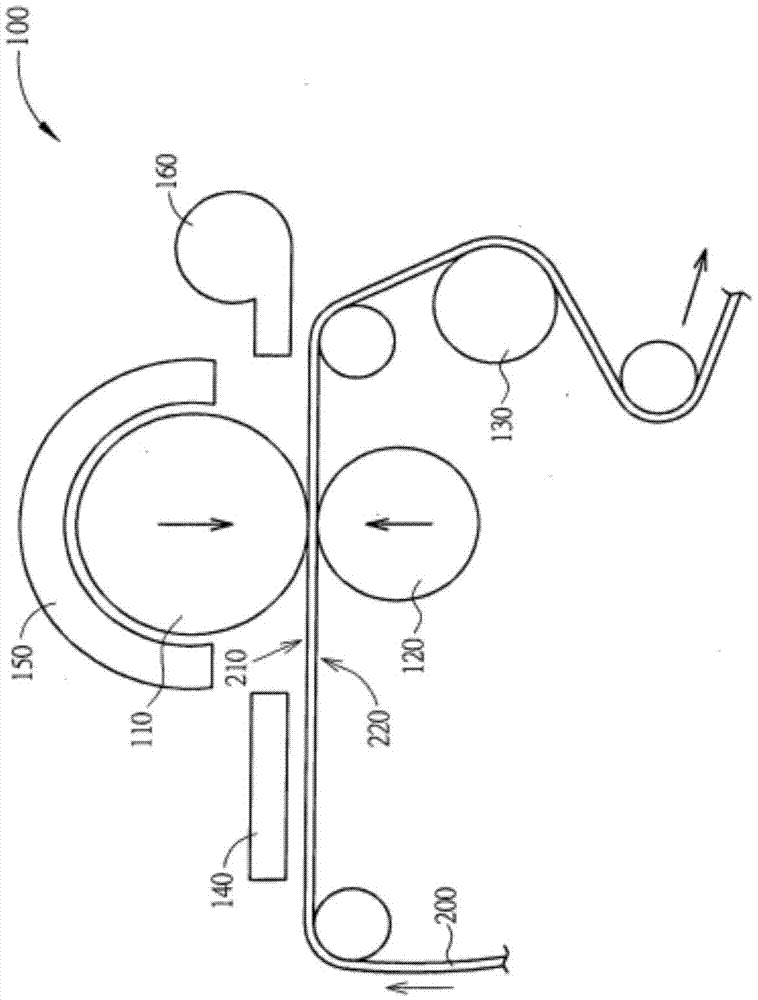

[0011] Such as figure 1 As shown, a film surface treatment equipment includes a first pressure roller 110 and a second pressure roller 120, the first pressure roller 110 is set correspondingly to the second pressure roller 120, and the first pressure roller 110 is located on the second Just above the pressure roller 120, a heating mantle 150 is arranged directly above the first pressure roller 110, and the heating mantle 150 is in the shape of a semicircle (for heating the surface of the first pressure roller 110, thereby making the first pressure roller 110 The surface temperature of the wheel is consistent), the upper half of the first pressure roller 110 is located in the heating cover 150; one side of the first pressure roller 110 is provided with a preheating device 140 (the preheating device 140 can preheat the film 200 , to prevent the temperature of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap