Tempered glass

A tempered glass and glass technology, applied in glass/slag layered products, chemical instruments and methods, coatings, etc., can solve the problems of unreasonable single structure, self-explosion of structure design, poor bending and seismic performance, etc. The effect of bending shock resistance, reducing self-explosion phenomenon and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

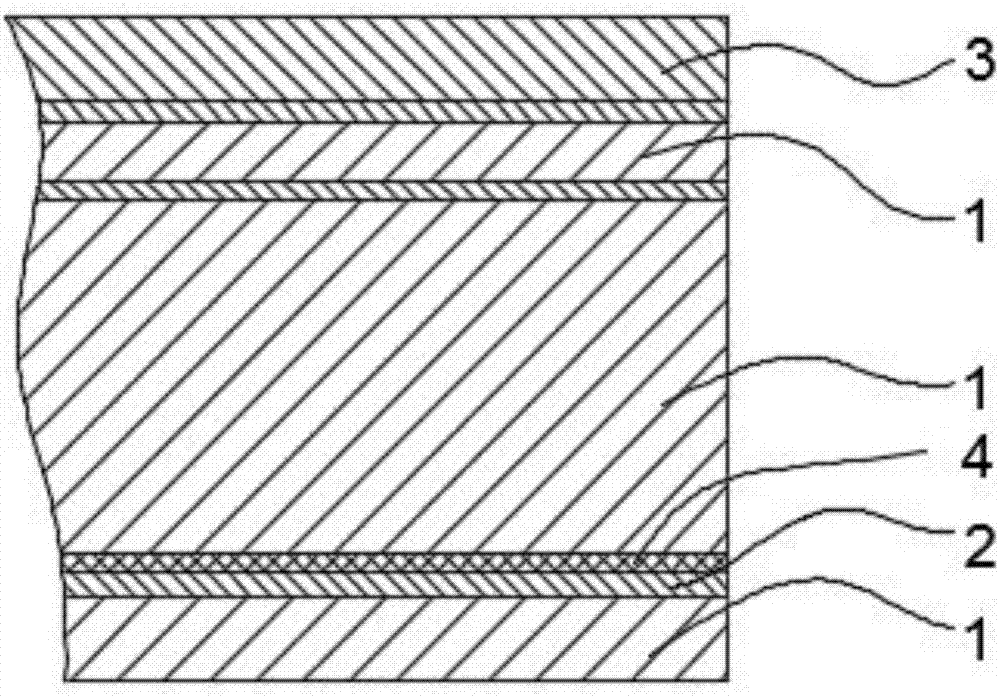

[0027] A tempered glass, comprising three layers of tempered glass layers 1 and an adhesive layer 2 for connecting each tempered glass layer 1, the adhesive layer 2 is a PVB film layer, and the thickness ratio of the three layers of tempered glass is 1:3-10: 0.5-2, one layer of plexiglass layer 3 is arranged on the outside of each toughened glass layer 1, and the thickness ratio of plexiglass layer 3 to the toughened glass layer 1 of the outer layer is 1:3-5, and the toughened glass of the outer layer here is One of the two layers on either side of the three layers. A conductive layer 4 is also provided between each tempered glass layer 1, and the thickness of the conductive layer 4 is 0.05-0.2mm. One method of the conductive layer 4 is to firstly bond the adhesive layer 2 to form an integral body, and then bond the tempered glass layer. This structure forms a three-layer tempered glass structure with thinner sides in the middle and back. Such a structure can avoid excessive ...

Embodiment 2

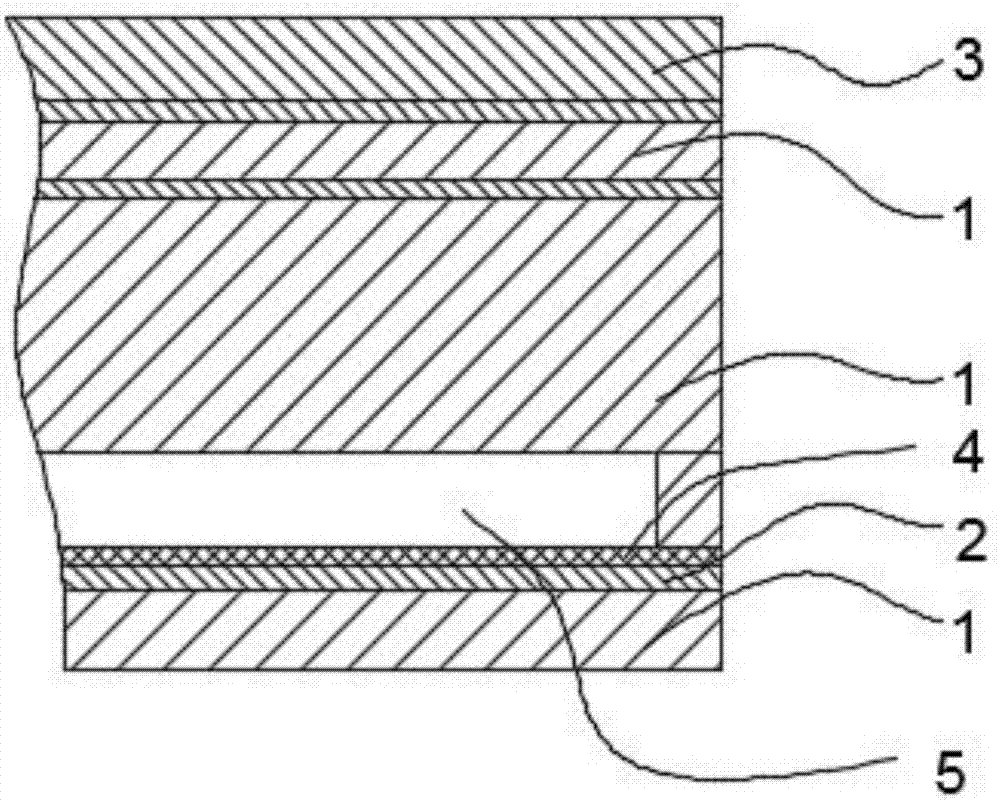

[0029] On the basis of Embodiment 1, a hollow layer 5 is provided between the three tempered glass layers 1 .

Embodiment 3

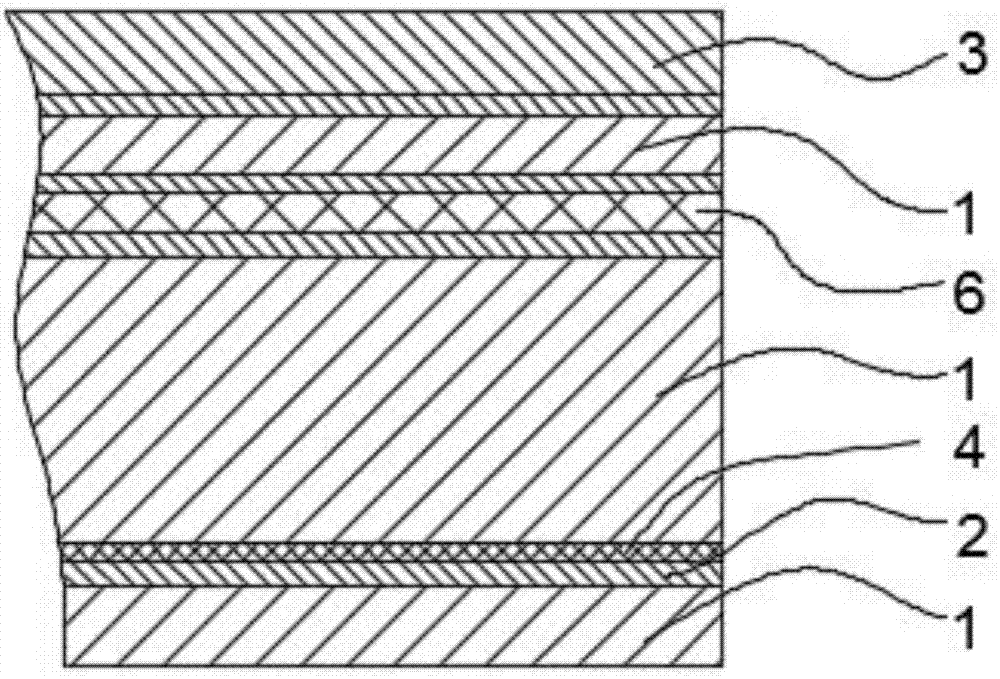

[0031] On the basis of embodiment 1 or 2, a polyester buffer layer 6 is provided between the three tempered glass layers 1, and the thickness of the polyester buffer layer 6 is 0.5-3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com