Back rest structure with adjustable height difference

A technology of difference and back beam, which is applied in the direction of weaving, textiles and papermaking, looms, etc., to achieve the effect of small transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

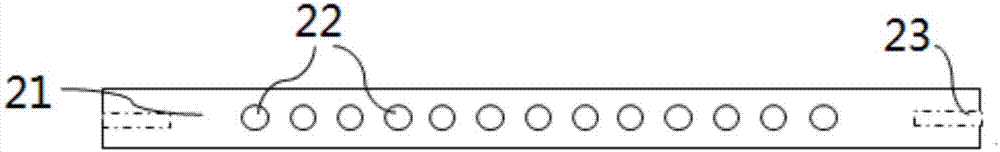

[0056] Embodiment: The preparation of a height difference-adjustable back beam structure mainly adopts a special back beam with height-adjustable insert rods. The specific method is as follows:

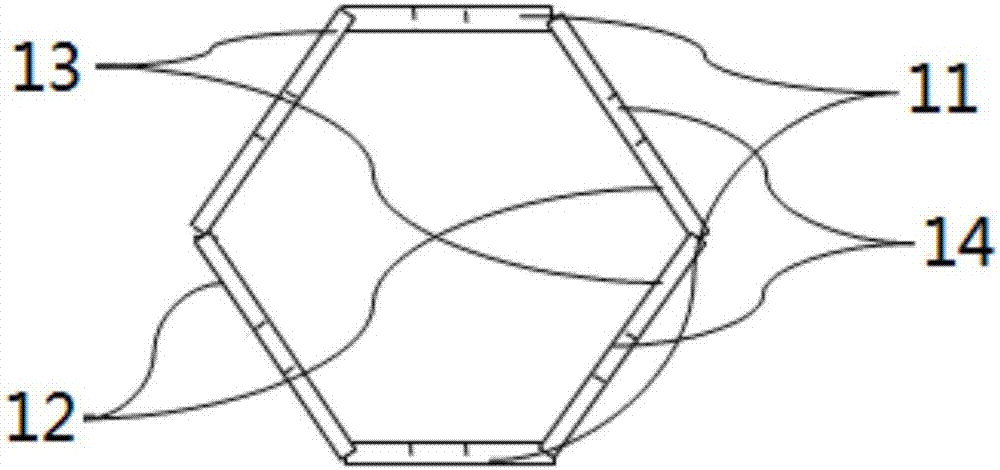

[0057] (1) Preparation of the central axis of the regular hexagon:

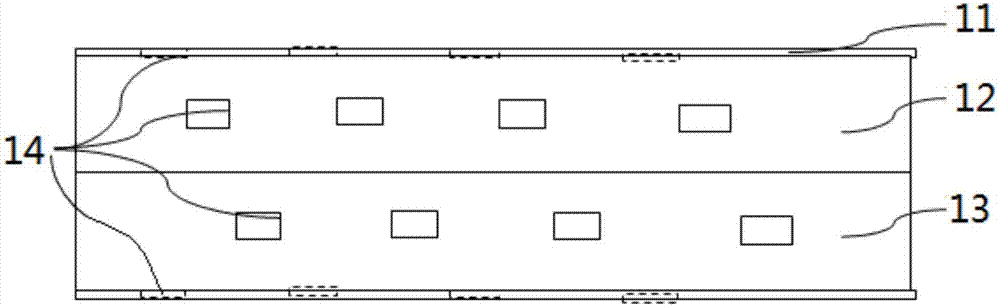

[0058] a. Make 6 strip metal plates with the same material, shape and size as the central axis panel, including two central axis panels A 11, two central axis panels B12, two central axis panels C13, and central axis panels The length is equal to the total width of the loom, the width ranges from 10mm to 20mm, and the thickness is 3mm to 5mm.

[0059] b. Set several rectangular rod holes 14 of the same shape and size on the central axis panel along the length direction. The length of the rectangular rod holes 14 along the length direction of the central axis panel is 5mm~20mm, and the width perpendicular to the length direction is 5mm~8mm ; The rectangular rod hole 14 is located in the middle of the central axis pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com