A roller structure that is easy to adjust

A technology of rollers and adjustment pieces, applied in roads, tracks, buildings, etc., can solve problems affecting the normal operation of roller devices, difficult manufacturing process, complicated installation and debugging, etc., achieve low cost, easy processing, and improve operation accuracy degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

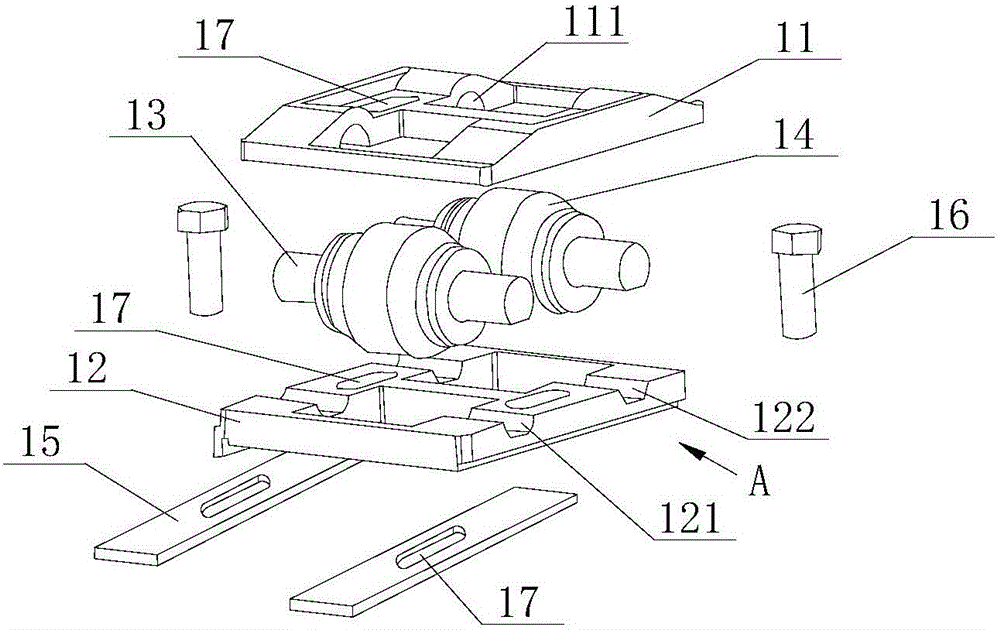

[0028] An easy-to-adjust roller structure, see figure 1 , comprising an upper frame 11, a lower frame 12, a roller body and an adjustment member 15, the roller body is arranged between the upper frame 11 and the lower frame 12, the overall structure is simplified and the cost is low.

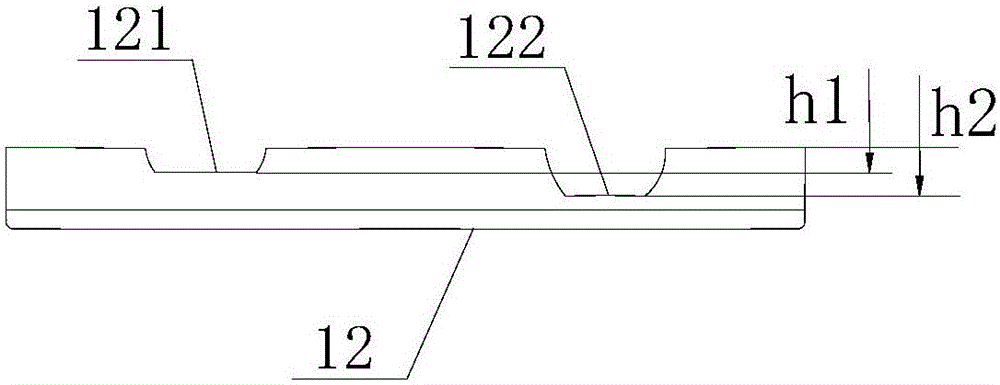

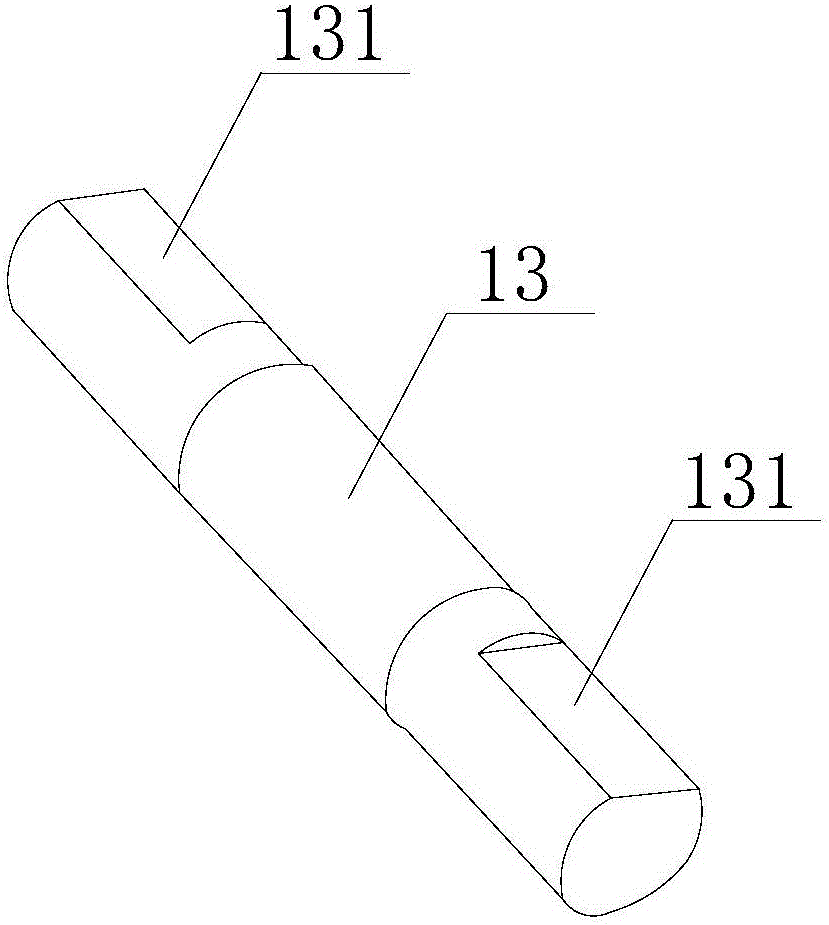

[0029] On the lower surface of the upper frame 11, two groups of upwardly concave installation grooves 111 are arranged in parallel; on the upper surface of the lower frame 12, there are parallel first grooves respectively corresponding to the installation grooves 111 and concave downward. 121 and the second card slot 122, when the upper frame 11 and the lower frame 12 are assembled, the installation groove 111 and the first card slot 121 and the installation groove 111 and the second card slot are formed. The two cavities formed by 122 facilitate the rapid positioning of the central axis 13 of the roller body during the assembly process.

[0030] The height h2 of the second card slot 122 is 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com