Automatic integrated stereo sewing machine

A sewing machine, fully automatic technology, applied in the direction of sewing machine components, program-controlled sewing machines, sewing equipment, etc., can solve the problems of a large number of human resources, low efficiency, low profit margins, etc., to reduce technical requirements, improve production efficiency, and technical level. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

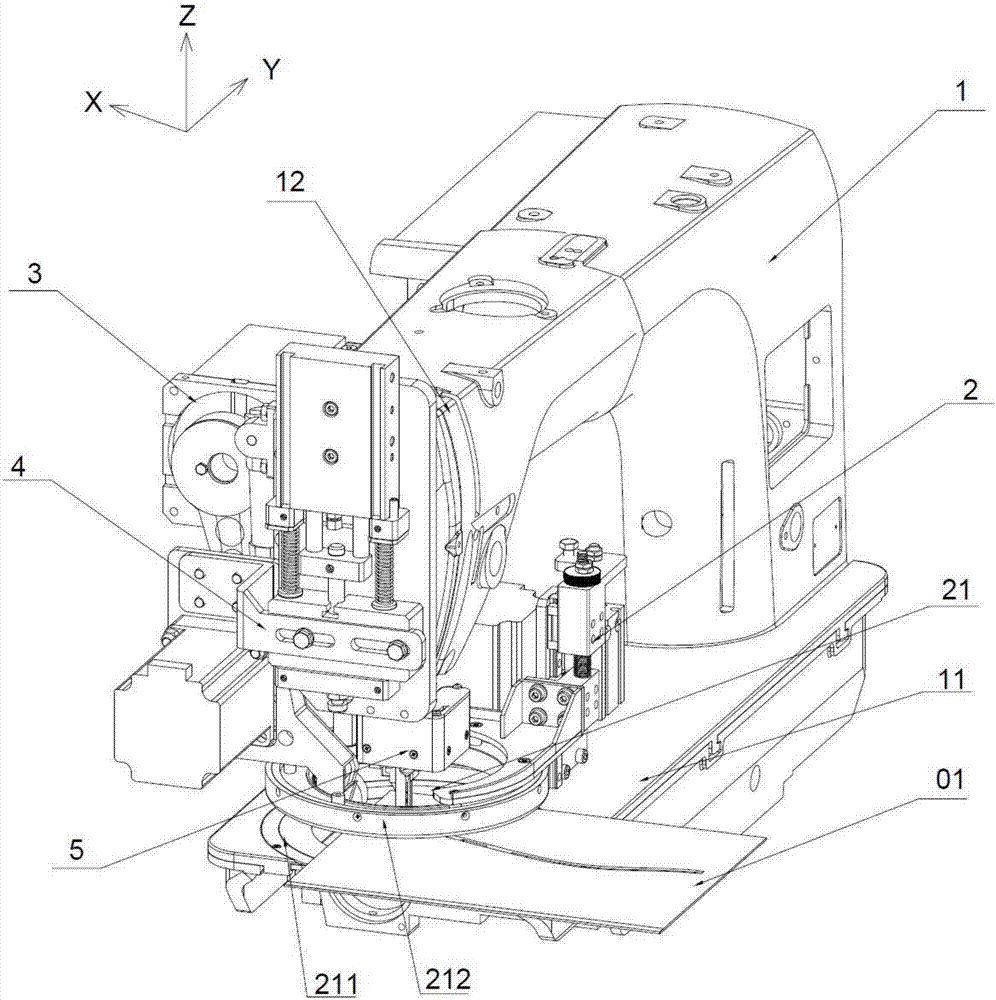

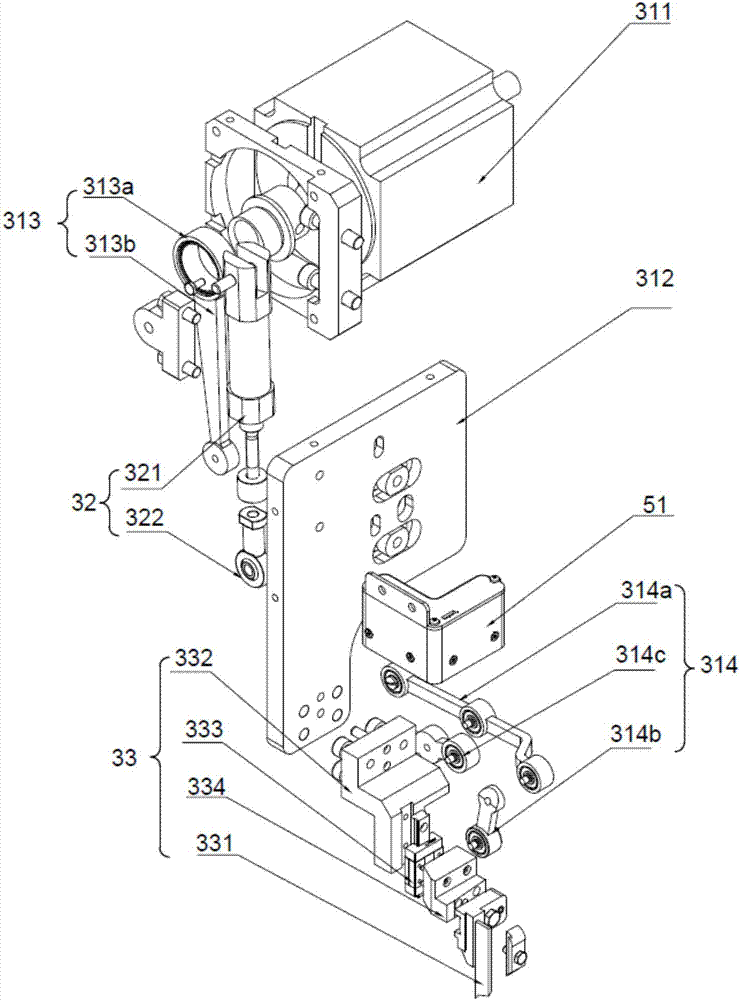

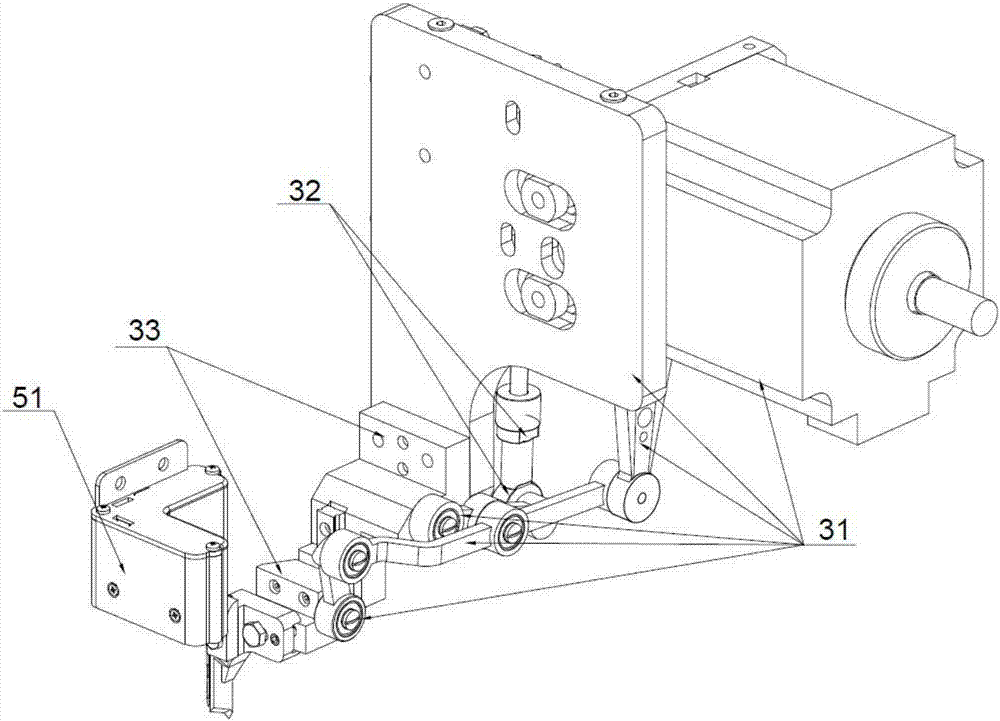

[0027] Example 1, such as Figure 1 to 7 As shown, a fully automatic integrated three-dimensional sewing machine of this embodiment, assuming that the cloth conveying direction is X direction, the cloth deflection direction is Y, and the vertical direction is Z direction, the integrated sewing machine includes a sewing machine main body for sewing 1. An edge-aligning mechanism capable of aligning the fabric 01 in the y-direction 2, a trimming mechanism capable of trimming the fabric 01 in the z-direction, 3, a mopping mechanism capable of dragging the fabric in the x-direction 4 and used to control the alignment Edge mechanism 2, trimming mechanism 3 and mopping mechanism 4 detection control system 5. The sewing machine main body 1 includes a table 11, a machine head 12 arranged on the table and a needle 13 located below the machine head; the side facing mechanism 2 has An offset-adjusting sewing working ring 21 arranged on the platen 11 and surrounding the axis of the needle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com