Well drilling bit for municipal public works

A drilling bit and engineering technology, which is applied in the direction of drill bits, drilling equipment, and driving devices for drilling in boreholes, etc., which can solve the problems of increased time cost, high cost, and uneconomical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to solve the above-mentioned defects in the prior art, the present invention discloses a drilling bit for municipal public works, which is realized by adopting the following technical solutions.

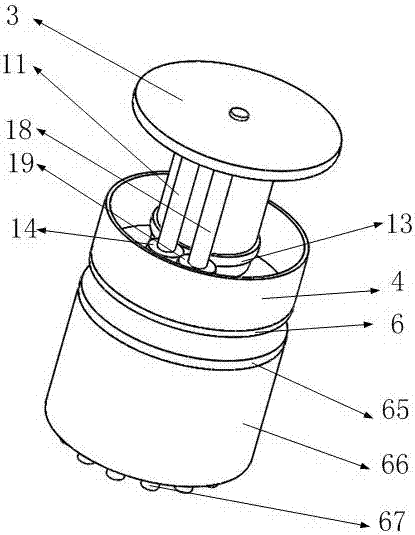

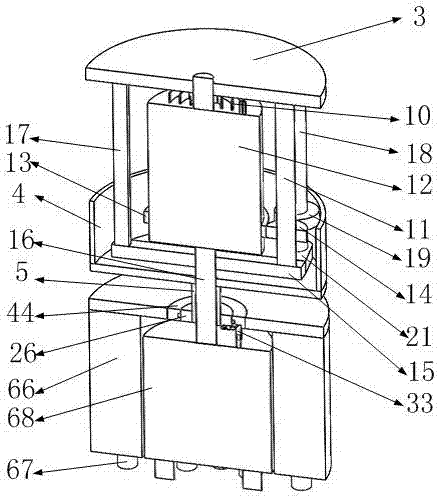

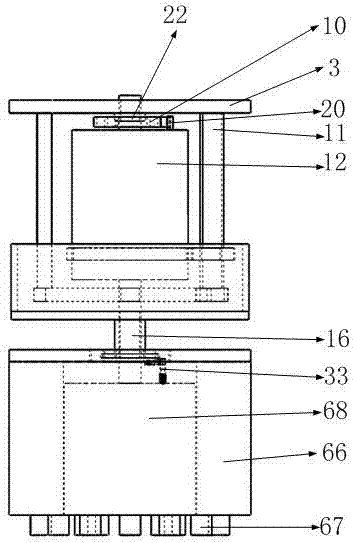

[0026] Such as figure 1 , 2, 3, 4, it includes ring gear 4, ring shaft 5, ring gear side wall 6, support top cover 8, scroll spring 9, second pole 11, motor 12, ring gear 13, first gear 14 , chassis plate 15, motor shaft 16, first pole 17, third pole 18, second gear 19, fixed structure 20, pole fixing plate 21, shaft sleeve 22, shaft hole 23, ring guide ring 25, Inner ring 26, block 33, block inner block 34, outer ring 44, trephine top cover 65, trephine shell 66, drill string 67, inner drill 68, top block 47, centrifugal block 48, centrifugal spring 50, ring Guide groove 51, arc-shaped side block 54, block spring 55, outer ring groove 56, outer ring arc groove 57, inner ring groove 58, inner ring centrifugal sleeve 59, top block slope 60, block slope 61, Among the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com