Coring drilling tool single-action device for preventing following moving of internal assembly

A core drilling tool and assembly technology, which is applied in the direction of extracting the undisturbed core device, earthwork drilling and mining, etc., can solve the problems of reducing the return footage and coring rate, reducing the original shape of the core, and reducing the drilling efficiency, so as to improve the quality of the core Quality and recovery rate, increase the number of rounds of footage, and improve the effect of drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

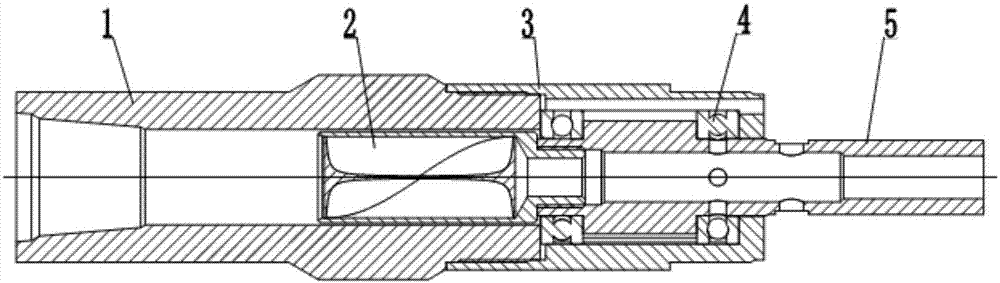

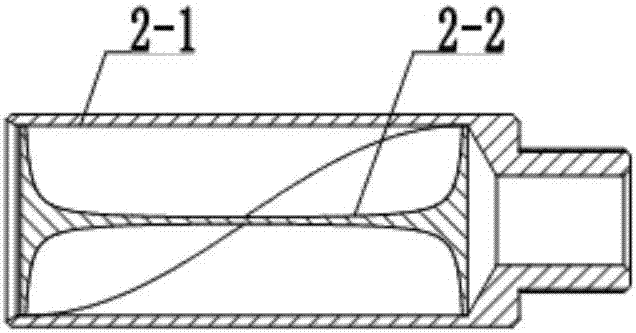

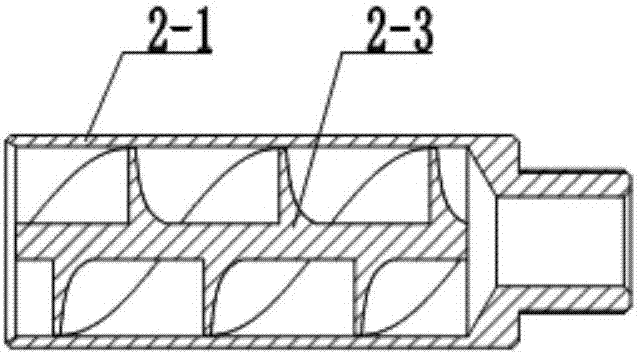

[0030] see figure 1 , a single-action device for core drilling tools that prevents the internal assembly from following, and is composed of an upper joint 1, a reversing mechanism 2, a bearing chamber 3, a single-action bearing 4 and a mandrel 5; the upper joint 1 and the bearing chamber 3 is assembled by screw connection; the mandrel 5 is installed in the bearing chamber 3 through the upper and lower rows of single-action bearings 4; the reversing mechanism 2 is fixed in the housing 2-1 by the cylindrical housing 2-1 The reversing impeller in the cavity is composed of the housing 2-1 fitted in the center hole of the upper joint 1 in a clearance fit manner, and its lower end is connected with the spindle 5 through a reverse thread structure; the housing of the reversing mechanism 2 The fit gap between the body 2-1 and the central hole of the upper joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com