Method for regulating liquid injection of a compressor, compressor and components for liquid injection

A technology of compressors and liquids, which is applied in the direction of liquid variable displacement machines, liquid fuel engines, components of pumping devices for elastic fluids, etc., and can solve problems such as indirect control of injection liquids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

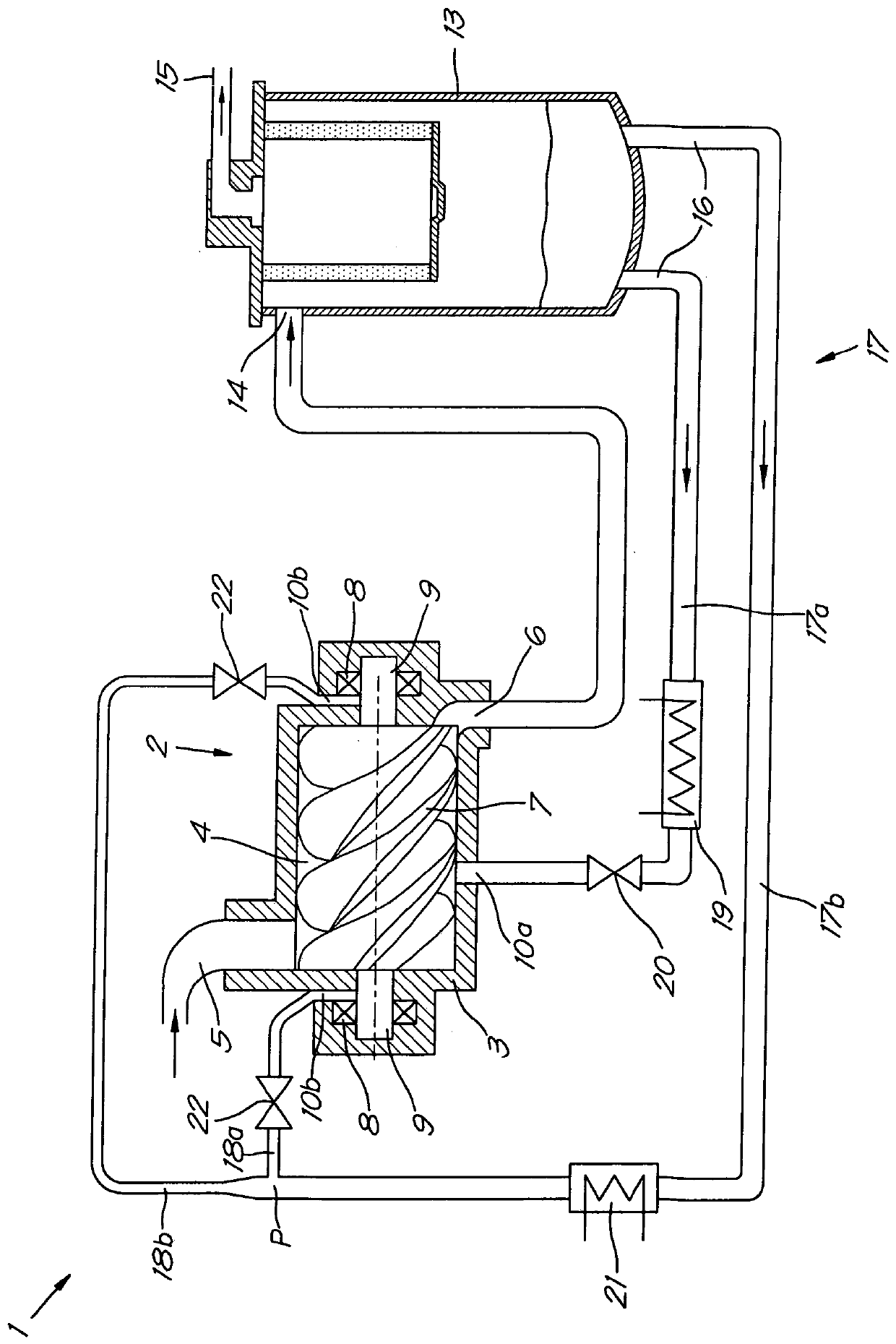

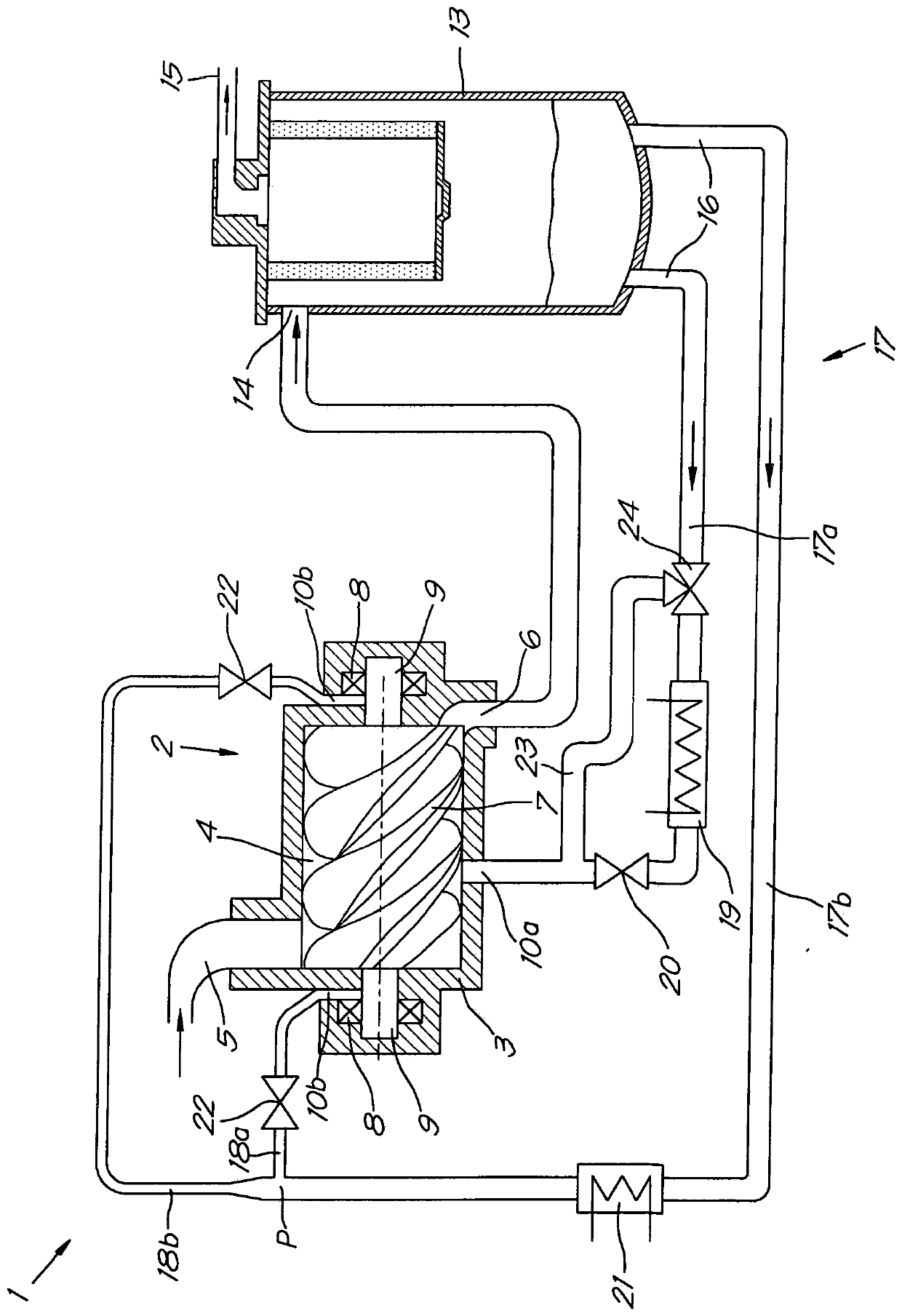

[0040] figure 1 The liquid-injected compressor device 1 shown in includes a liquid-injected compressor element 2.

[0041] The compressor element 2 comprises a housing 3 which defines a compression space 4 and a gas inlet 5 and an outlet 6 for compressed gas.

[0042] One or more rotors 7 are rotatably attached in the housing 3 through bearings 8 attached to the shaft 9 of the rotor 7.

[0043] Furthermore, the housing 3 is provided with a large number of injection points 10a, 10b for injecting liquid.

[0044] The liquid may be, for example, synthetic oil or water, but the present invention is not limited to this.

[0045] The injection points 10a, 10b are provided at the position of the compression space 4 and the position of the aforementioned bearing 8.

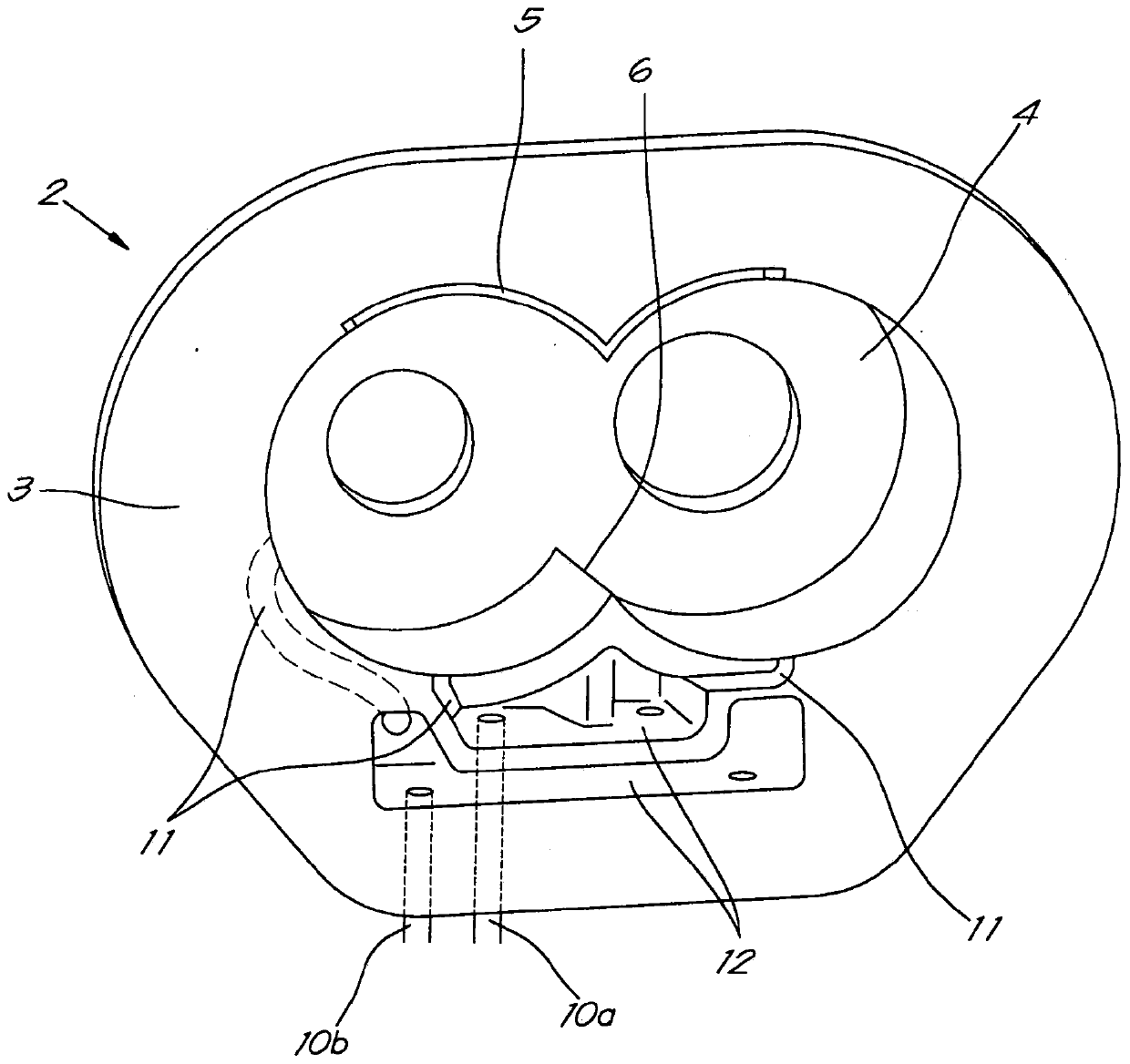

[0046] in figure 2 The compressor element 2 is shown in more detail in, on which injection points 10a, 10b are provided.

[0047] According to the present invention, the housing 3 is provided with separate integrated channels 11, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com