A Phase Shift Compensation Method for Single Resistor Current Sampling

A technology of current sampling and compensation method, applied in the direction of measuring current/voltage, measuring electrical variables, instruments, etc., can solve the problems of inaccurate current sampling, change of duty cycle, inaccurate control, etc., to achieve flexible sampling, simple algorithm, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

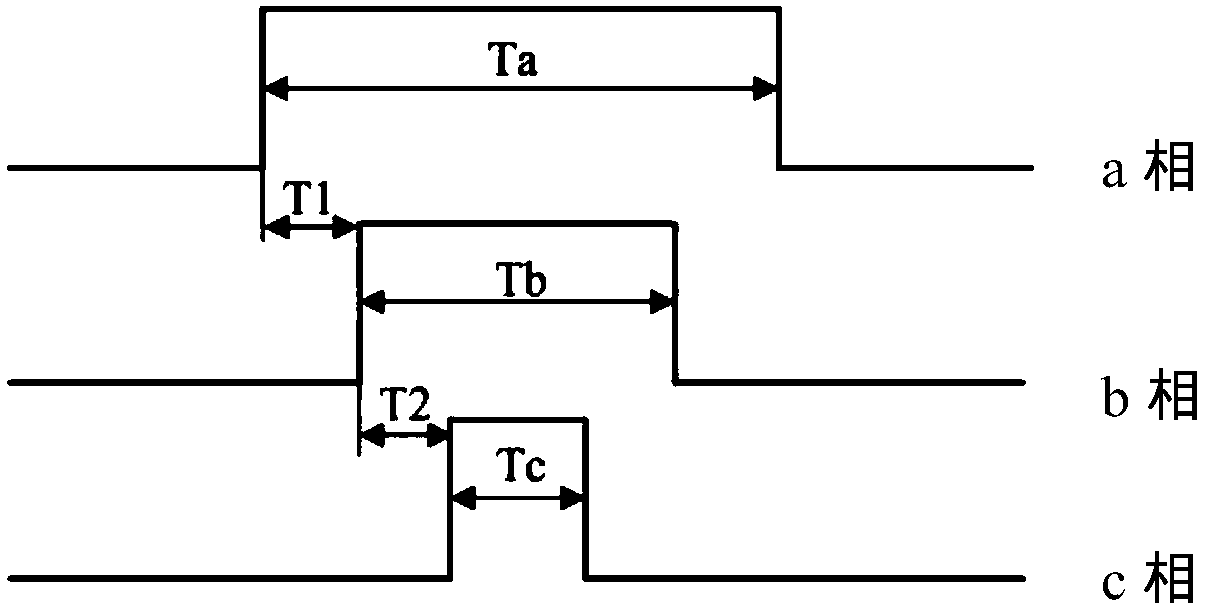

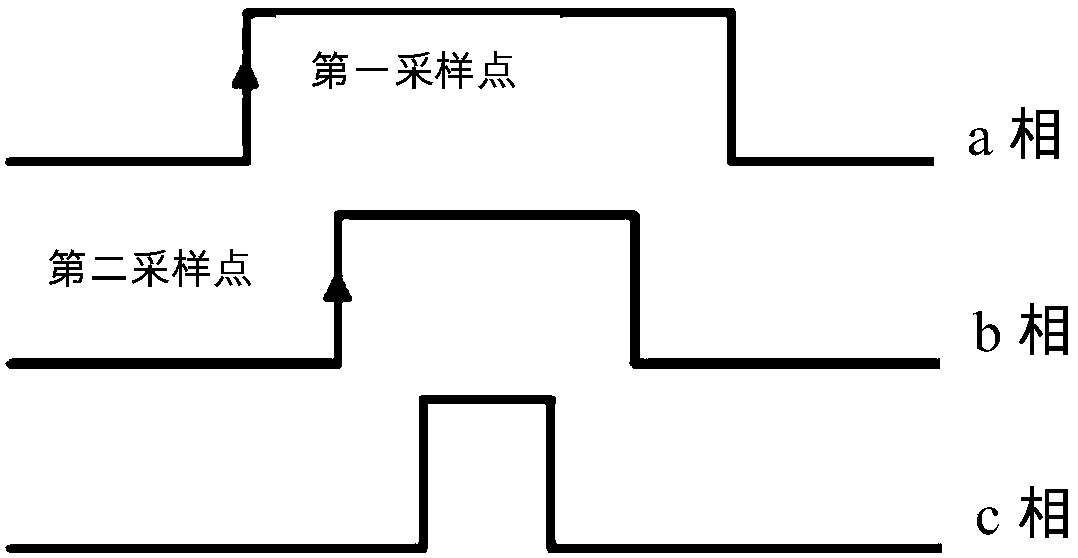

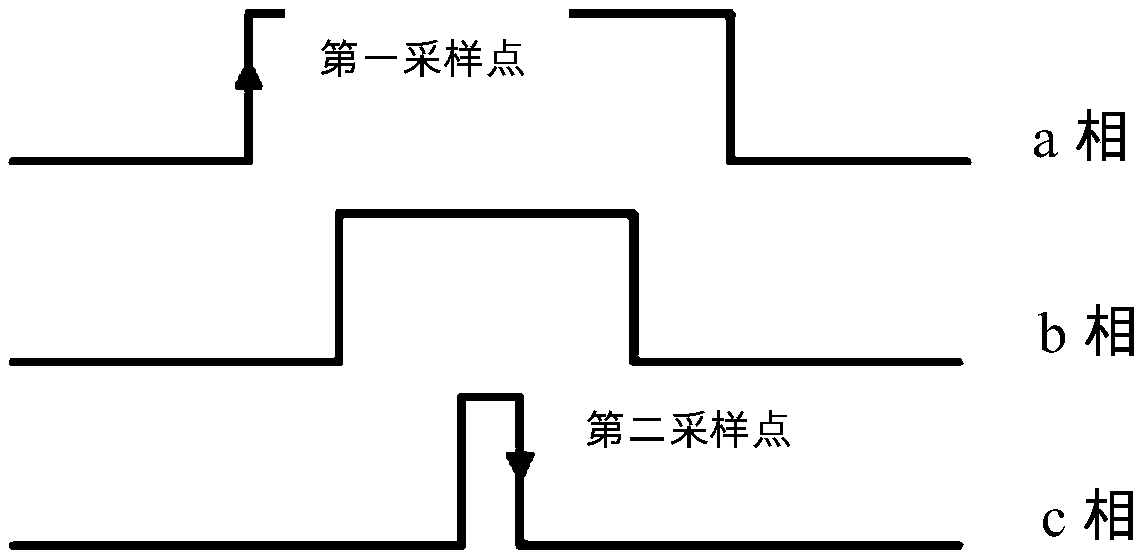

[0032] The embodiment of the present invention discloses a phase-shift compensation method for single-resistance current sampling. The method includes the following steps: S10), determining T1 and T2 according to Ta, Tb, and Tc, wherein T1 is the matching time of the first sampling point, and T2 is The second sampling point matches the time. Ta is the duty cycle time corresponding to the maximum duty cycle in the a, b, and c three-phase PWM signals, and Tb is the corresponding time in the middle of the duty cycle in the a, b, and c three-phase PWM signals. Duty ratio time, Tc is the duty ratio time corresponding to the minimum duty ratio in the a, b, c three-phase PWM signals; S20), judge whether T1+T2 is greater than 2*Tmin, if yes, execute step S31), If not, execute step S32), wherein, Tmin is the minimum current sampling time; S31), judge whether T1 is greater than or equal to Tmin, if yes, execute step S41), if not, shift the intermediate phase of the duty ratio Execute st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com