Batch sequential printing method and device for CAD drawings

A technology of sequential printing and drawing, applied in the direction of digital output to printing unit, data processing input/output process, instruments, etc., can solve the problems of low printing efficiency, inability to print, and small adaptability, and achieve simple structure and easy implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

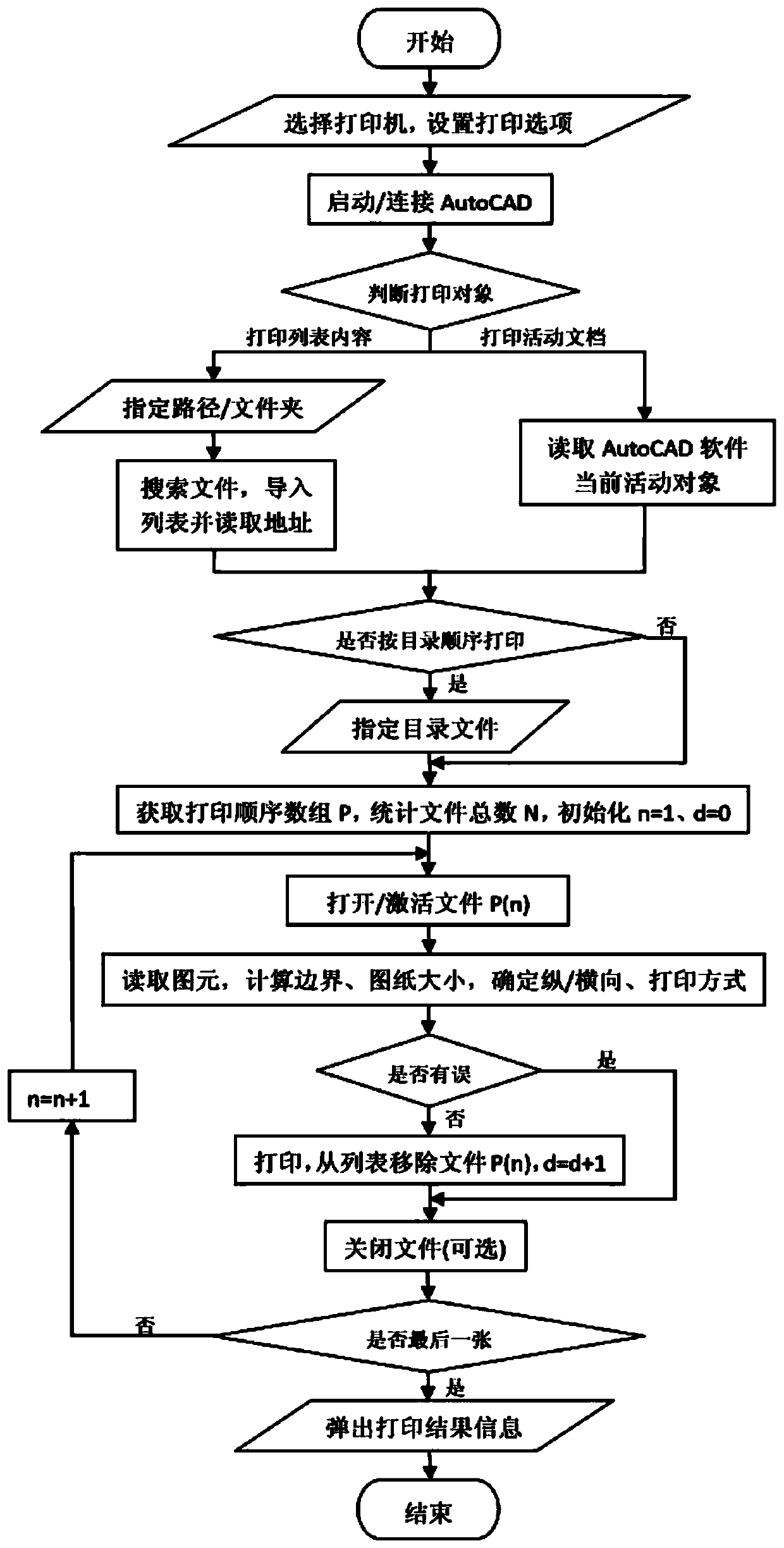

[0055] like figure 1As shown, the batch sequential printing method of the CAD drawings of the present embodiment, the steps are:

[0056] S01, start or connect the AutoCAD software, and connect with the printing device, and complete the setting of batch printing information;

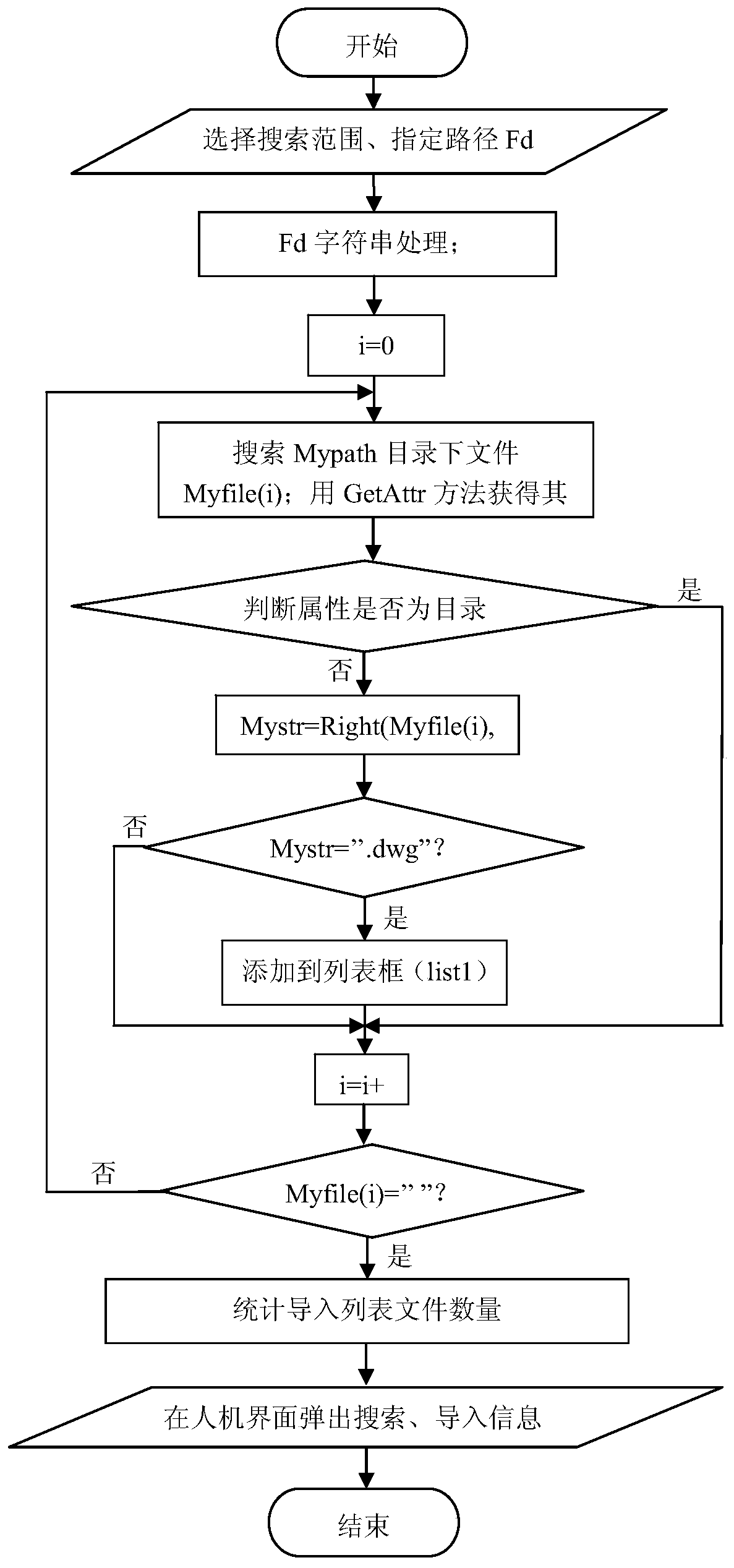

[0057] S02, read the print object: when the selected print object is "print active document", read all the current active objects of AutoCAD software; when the selected print object is "print list content", then search all CADs under the specified range or path file, and read the corresponding address;

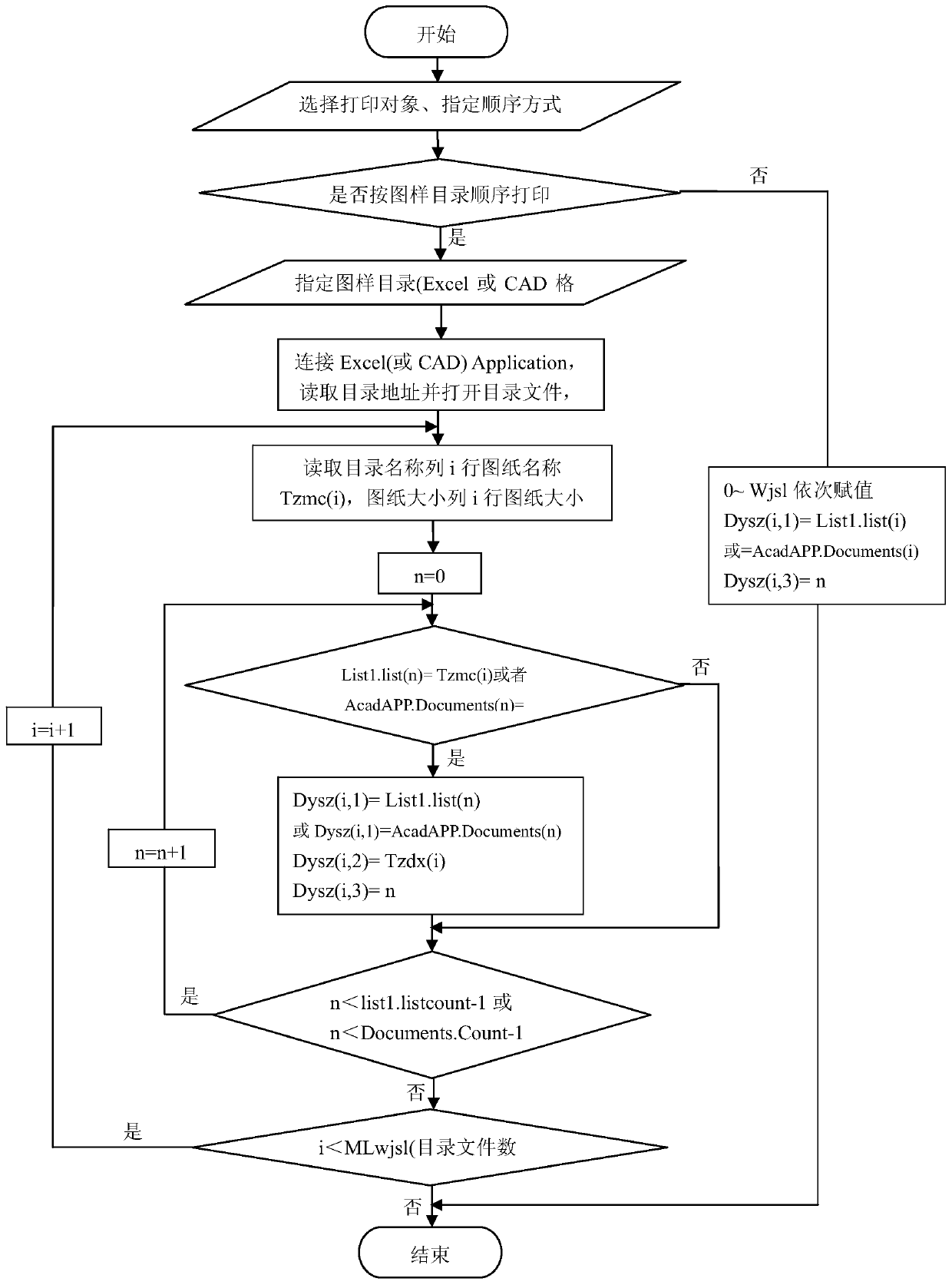

[0058] S03. Establish a print order array: sort the print objects in order to generate a two-dimensional array Dysz (1 to N, 1 to 3), wherein the first dimension represents the serial number, and the second dimension represents the drawing information of each file, incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com