Pre-encapsulated multi-lateral side immerseable lead frame structure and manufacturing method of lead frame structure

A frame structure and wire-wetting technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as unsatisfactory bonding ability, limited wettable area, and increased production costs, and achieve superior winding capacity , increase the wettable area, prevent the effect of falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

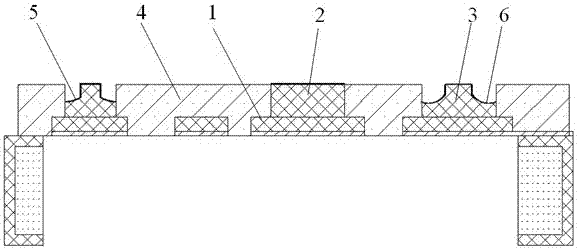

[0038] see figure 1 , figure 2 , a pre-encapsulated multi-sided wettable lead frame structure in this embodiment, it includes a first metal layer 1, the front side of the first metal layer 1 is provided with a base island 2 and pins 3, the first The periphery of the metal layer 1, the base island 2 and the pin 3 is filled with a pre-encapsulated insulating material 4, the front of the pre-encapsulated insulating material 4 is flush with the front of the base island 2 and the pin 3, and the pre-encapsulated insulating material 4 The back side is flush with the back side of the first metal layer 1, and grooves 5 are formed on the edges around the front side of the pin 3;

[0039] The pre-encapsulated insulating material 4 adopts insulating materials such as molding compound, ABF film, insulating glue, etc.;

[0040] The surfaces of the base ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap