A production method of a bright stainless steel pot and its special mold

The technology of a stainless steel pot and production method, which is applied to other household appliances, kitchen appliances, household appliances, etc., can solve the problems of rust, easy cracking, and adverse human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

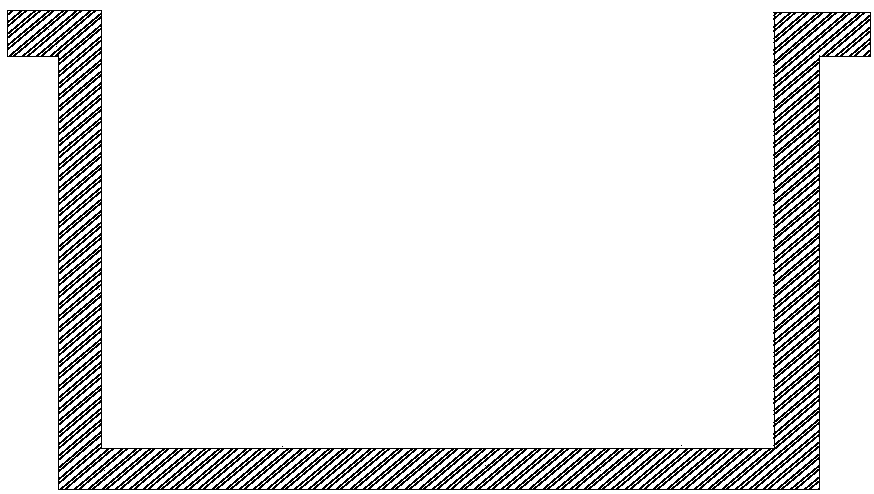

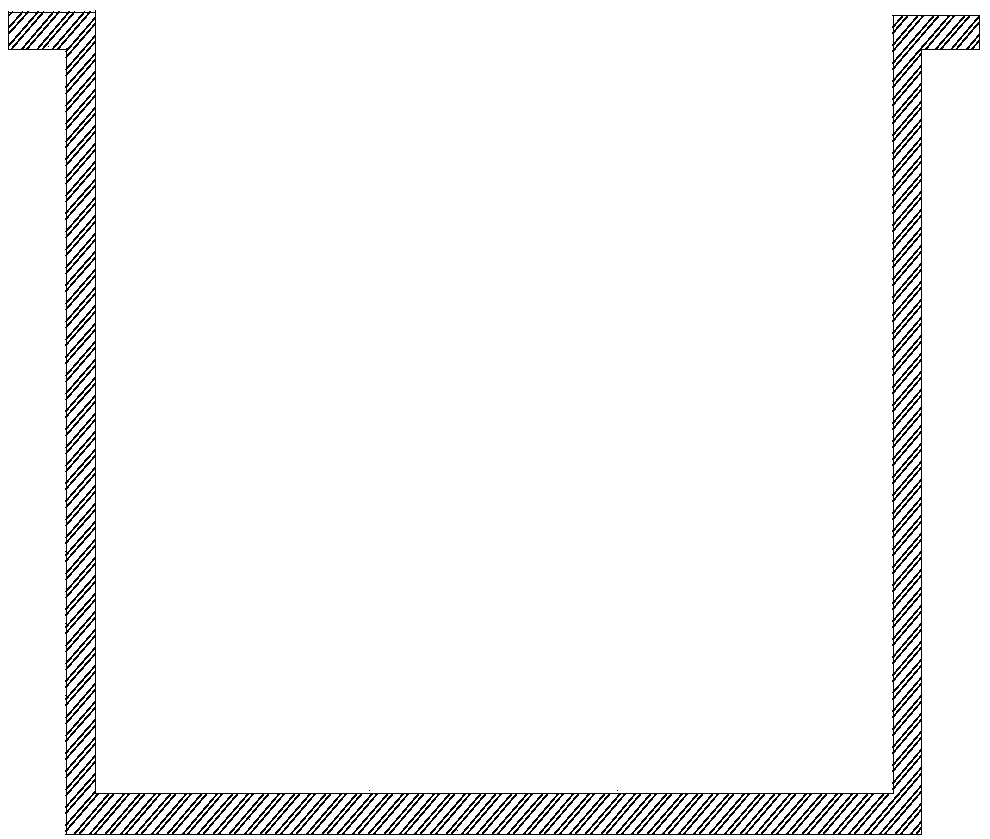

Image

Examples

specific Embodiment

[0025] Step 1. Material selection and blanking

[0026] First of all, symmetrical stainless steel plate is selected as the material, and the elongation rate of the material is 30% to 50%. The selected material is blanked, and the blank size is 700×600mm 2 For example, strictly control the peripheral edge (also called "overflow") of cutting material to be less than 0.15mm, so as to prevent the peripheral edge from being too large and causing the material to overflow to the periphery during the subsequent stretching process, resulting in waste of material. After cutting the material, set up the mold, carefully check the normal working status of the machine before setting up the mold, professional mold-setting technicians regularly add lubricating oil to the mold and its guiding working parts, and after the mold is set up and adjusted, put the stainless steel plate into the adjusted mold In the final mold (in the following mold processes, the steps of mold adjustment and mold adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com